Method for automatically filling mineral insulated electric cable

A technology for mineral insulated cables and automatic filling, which is applied in the manufacture of cables/conductors, circuits, and electrical components. It can solve the problems of low qualified rate of finished products, high production costs, and high labor intensity, and achieve high labor intensity and high production efficiency. The effect of high and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] 1. Clean and decontaminate the copper pipe 3 and wire core 1, put them in the tank for cleaning, put an appropriate amount of water in the cleaning tank, add 1% industrial cleaning agent, and carefully clean the outer surface of the copper tube by hand, the copper The inner surface of the tube needs to be scrubbed with a bougie, annealed and straightened, and the rough part of the copper tube mouth is smoothed to facilitate assembly. After the water on the surface is dissipated, the wire core is inserted into the copper tube and assembled. One end of the copper tube is closed and fixed into a core copper tube with a plug and a terminal cap;

[0023] 2. Magnesium oxide powder 2 is baked at 950°C to remove carbon, magnetic substances and moisture, and is kept at 250°C to 300°C.

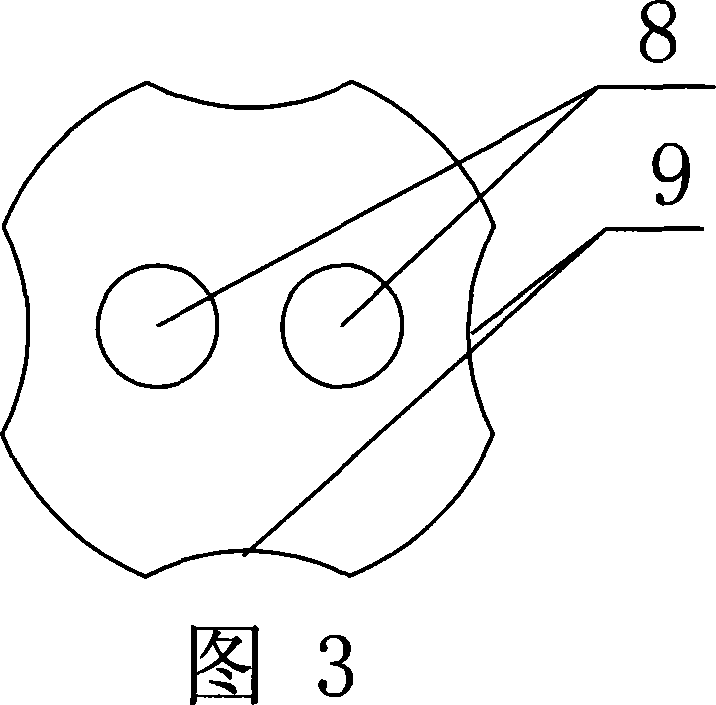

[0024] 3. A tamping mechanism consisting of a bracket 7, a tamping rod 5, a tamping head 4, and a weight 6 is adopted. The tamping head is installed and connected to the lower end of the tamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com