Method for fastly analyzing chemical oxygen demand by high-pressure flowing injection

A technology of flow injection and analytical chemistry, applied in the field of water environment monitoring and analysis, can solve the problems such as the inability to obtain a constant flow of the measured liquid in the flow cell, the interference of colorimetric measurement, and the poor measurement accuracy, so as to curb the generation of bubbles and avoid inconvenience. Adaptation, the effect of a wide measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

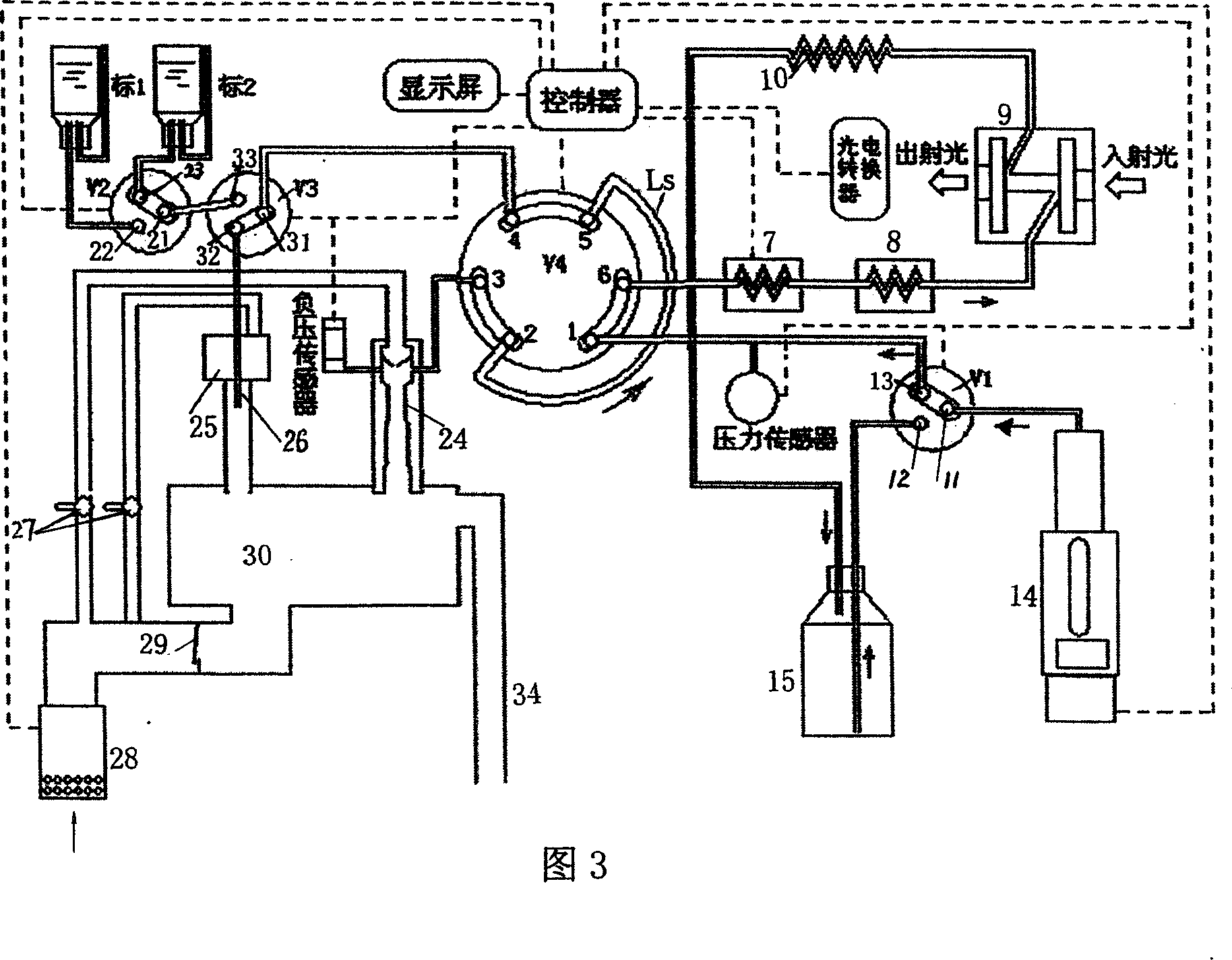

[0023] The principle of the present invention will be explained below in conjunction with Figure 1

[0024] Figure 1 shows the principle flow chart of the method. The pipelines in the figure are all corrosion-resistant fluoroplastic capillary tubes, and a water sample injection valve is connected to the capillary line. Potassium dichromate reagent is continuously delivered by a constant flow pump (pressure ≥ 0.6MPa), flows through the constant temperature heater, cooling water tank, colorimetric flow cell, and returns to the reagent bottle after coming out of the flow cell through a back pressure tube of tens of meters long Inside, a continuous flow of potassium dichromate carrier fluid is formed. During detection, the water sample injection valve is turned to the test position. When the injection valve cuts the water sample into the reaction tube, the sample tape is pushed by the carrier fluid and gradually diffused during the advancement process, and the sample and reagents pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com