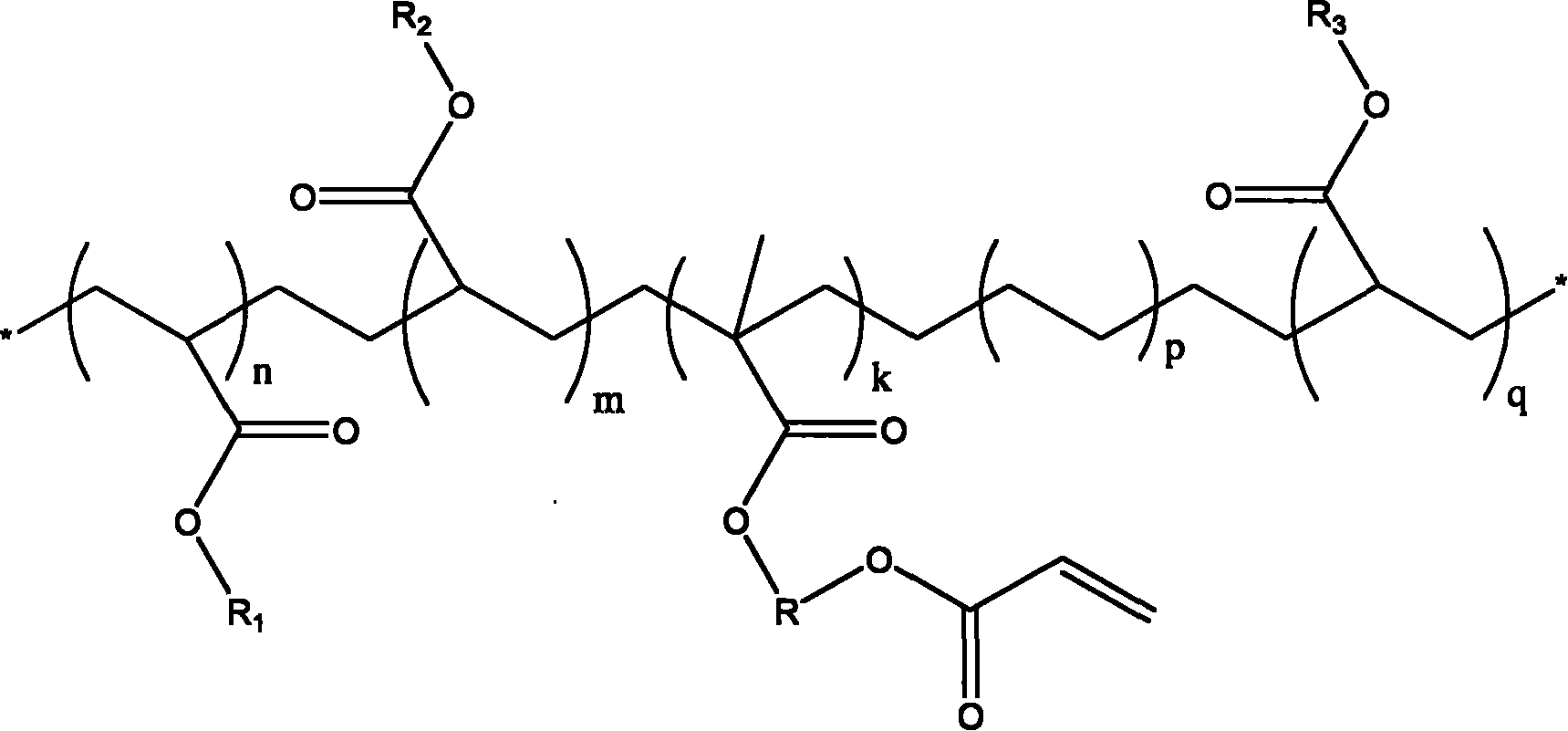

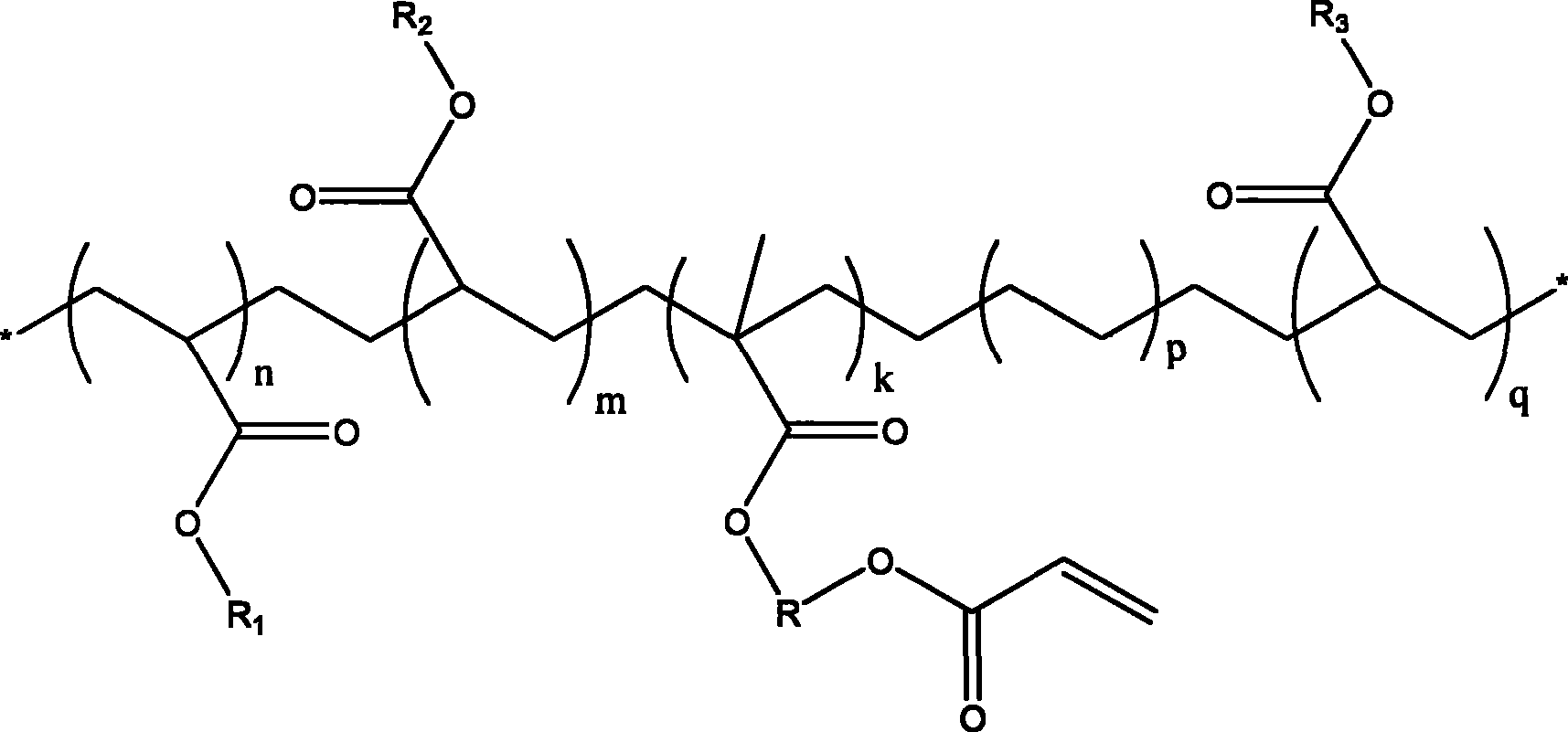

Esterified acrylie-ester high-polymer, its synthesis and use

A technology of acrylates and acrylates, used in the synthesis of special additives, the formulation of cationic photopolymerization systems, and the field of free radicals. It can solve problems such as difficult surface coating, and achieve easy operation, good solubility and simple synthesis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] One, the preparation method of acrylate polymer:

[0028] Under the conditions of stirring and nitrogen protection, thermal polymerization reaction of thermal initiator benzoyl peroxide and acrylate mixture with a monomer content of 0.1-3% in a toluene solution with a concentration of 30-70% An acrylic polymer; wherein, the polymerization temperature is 65-100° C., and the polymerization time is 3-10 hours.

[0029] The above-mentioned acrylate is ethyl acrylate, or butyl acrylate, or glycidyl methacrylate, or octyl acrylate, or acrylic acid, or lauryl acrylate, or octadecyl acrylate, or hydroxyethyl acrylate, or hydroxy acrylate Propyl ester, or propyl acrylate, or at least any one of methyl acrylate.

Synthetic example 1

[0031] Ethyl Acrylate (25% by weight), Butyl Acrylate (20%), Glycidyl Methacrylate (5%), Octadecyl Acrylate (5%), Hydroxyethyl Acrylate (20%), Methyl Acrylate A total of 100 grams of ester (25%) was added in 100 grams of toluene, 0.1 gram of benzoyl peroxide was added, the temperature was raised to 80° C., and the product was used for further reaction after 10 hours of reaction.

Synthetic example 2

[0033] Octyl Acrylate (30%), Butyl Acrylate (20%), Glycidyl Methacrylate (10%), Lauryl Acrylate (5%), Hydroxypropyl Acrylate (20%), Propyl Acrylate (15%) %)) was added into 50 grams of toluene in total, 0.5 gram of benzoyl peroxide was added, the temperature was raised to 65° C., and the product was used for further reaction after 6 hours of reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com