Method for extracting cholesterine in lanosterol by supercritical CO2

A technology for lanolin and cholesterol, applied in the field of cholesterol, can solve the problems of low purity and yield of cholesterol, and achieve the effects of reducing chemical consumption, light color and omitting refining steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

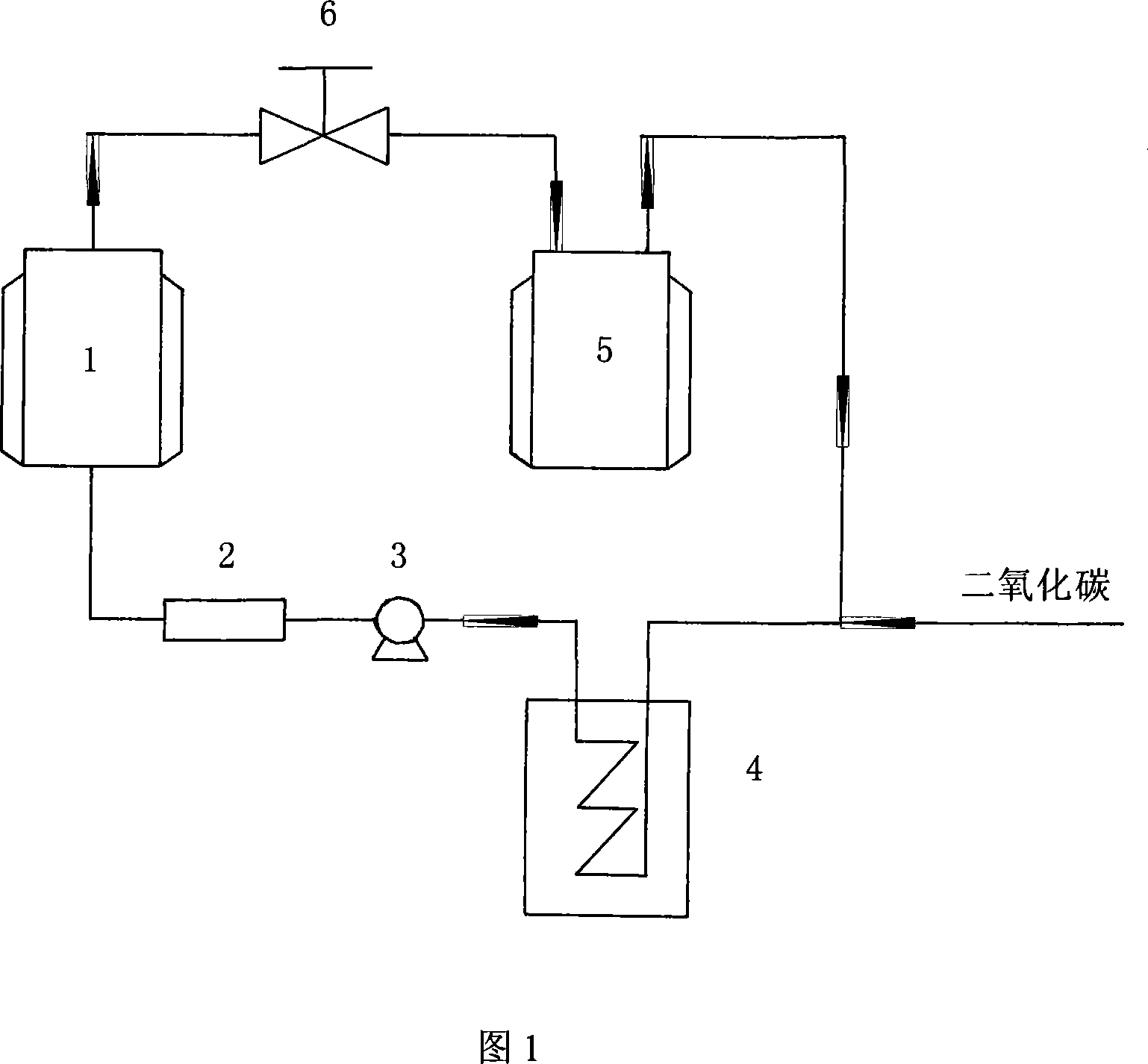

[0028] Referring to Fig. 1, put 100g of lanolin alcohol into 1L extractor 1 after heating and melting, add 30ml of ethanol, seal the extractor, open the gas valve of the carbon dioxide steel cylinder, and make the carbon dioxide pressure reach 35Mpa through circulating cooler 4 and high-pressure pump 3. The critical carbon dioxide is preheated to 45°C by the preheater 2, enters the extractor 1, and extracts for 120 minutes. After the pressure is released and reduced by the pressure regulating valve 6, 78.0 g of lanolin alcohol is obtained in the separation kettle 5, and the extraction residue is obtained in the extractor. After dissolving with 70ml of ethanol, 17.5g of cholesterol was obtained after cooling down and crystallizing, with a cholesterol content of 95.2%.

Embodiment 2

[0030] Similar to Example 1, heat and melt 80g of lanolin alcohol into a 1L extractor, add 35ml of water, seal the extractor, open the gas valve of the carbon dioxide steel cylinder, and make the carbon dioxide pressure reach 35Mpa through a circulating cooler and a high-pressure pump, supercritical Carbon dioxide is preheated to 50°C by the preheater and enters the extractor. After 300 minutes of extraction, the pressure regulating valve is released to reduce pressure, and 60.3g of lanolin alcohol is obtained in the separation kettle. The extraction residue obtained in the extractor is dissolved in 60ml of ethanol and then cooled. After crystallization, 12.0 g of cholesterol was obtained, with a cholesterol content of 93.7%.

Embodiment 3

[0032] Similar to Example 1, heat and melt 80g of lanolin alcohol and put it into a 1L extractor, add 35ml of acetone, seal the extractor, open the gas valve of the carbon dioxide steel cylinder, and make the carbon dioxide pressure reach 25Mpa through a circulating cooler and a high-pressure pump, supercritical Carbon dioxide is preheated to 50°C by the preheater and enters the extractor. After extraction for 120 minutes, the pressure regulating valve is released to reduce the pressure, and 63.6g of lanolin alcohol is obtained in the separation kettle. The extraction residue obtained in the extractor is dissolved in 80ml of ethanol and then cooled. After crystallization, 13.04 g of cholesterol was obtained, with a cholesterol content of 94.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com