Method for producing high-temperature alpha-amylase by thermococcaceae aeropyrum pernix and product thereof

A technology of thermophilic archaea and cocci, applied in the direction of biochemical equipment and methods, enzymes, bacteria, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

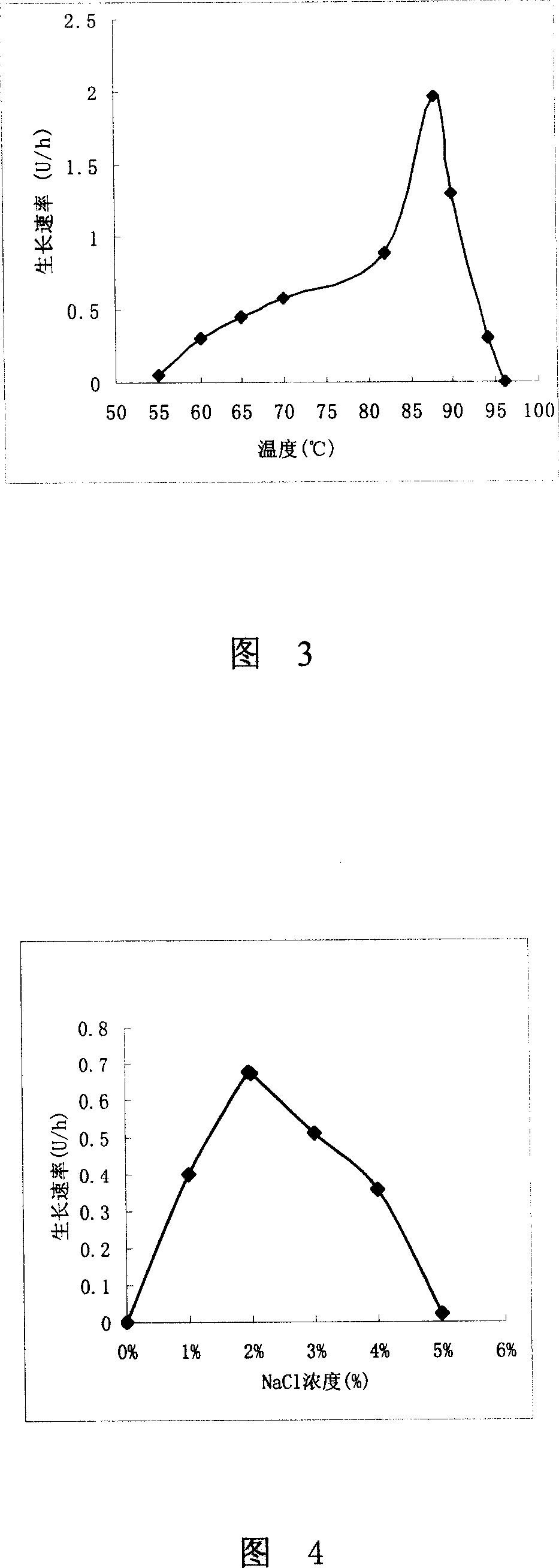

[0063] Example 1. A Thermococcus siculi HJ21 (Thermococcus siculi HJ21) CCTCC NO: M 207010. The strain has the following characteristics: the strain is a strictly anaerobic coccus with a diameter of 0.5-1um; the growth temperature range of the strain is 55-94°C, and its optimum growth temperature is 88°C; the optimum growth pH range is 6.5-7.0, low The strain does not grow at 4.5 or higher than 9.0; the growth NaCl concentration range is 1-5%, 2% is the most suitable NaCl concentration, no NaCl and higher than 5% do not grow; the strain grows well in protein-rich substrates; starch, Maltose, glucose, sucrose, cellobiose, lactose, glycogen, gelatin promote the growth of the strain.

Embodiment 2

[0064] Example 2. Utilize the method for thermostable acid α-amylase produced by Thermococcus thermophilic archaea HJ21 CCTCC NO: M207010 described in Example 1, the steps are as follows,

[0065] (1) Inoculate the strain in YPS medium with a pH of 6.5, and cultivate it at 88°C for 8-9 hours; take out the fermentation broth and cool it to room temperature, filter and remove sulfur particles with a vacuum circulation pump, and then centrifuge at 11000rpm / min for 20min. supernatant to obtain crude enzyme liquid;

[0066](2) Add ammonium sulfate powder to the crude enzyme solution to 70% saturation, stir while adding, continue to stir for 15 minutes after the addition, and then place it in a 4°C incubator for 12 hours; then 11000r / min, 20min Collect the precipitate by centrifugation, add an appropriate amount of 50mM Tris-HCl buffer solution with a pH of 7.5 to dissolve, put the salted out solution in a dialysis bag, place it at 4°C, and dialyze it with a 50mM Tris-HCl buffer so...

Embodiment 3

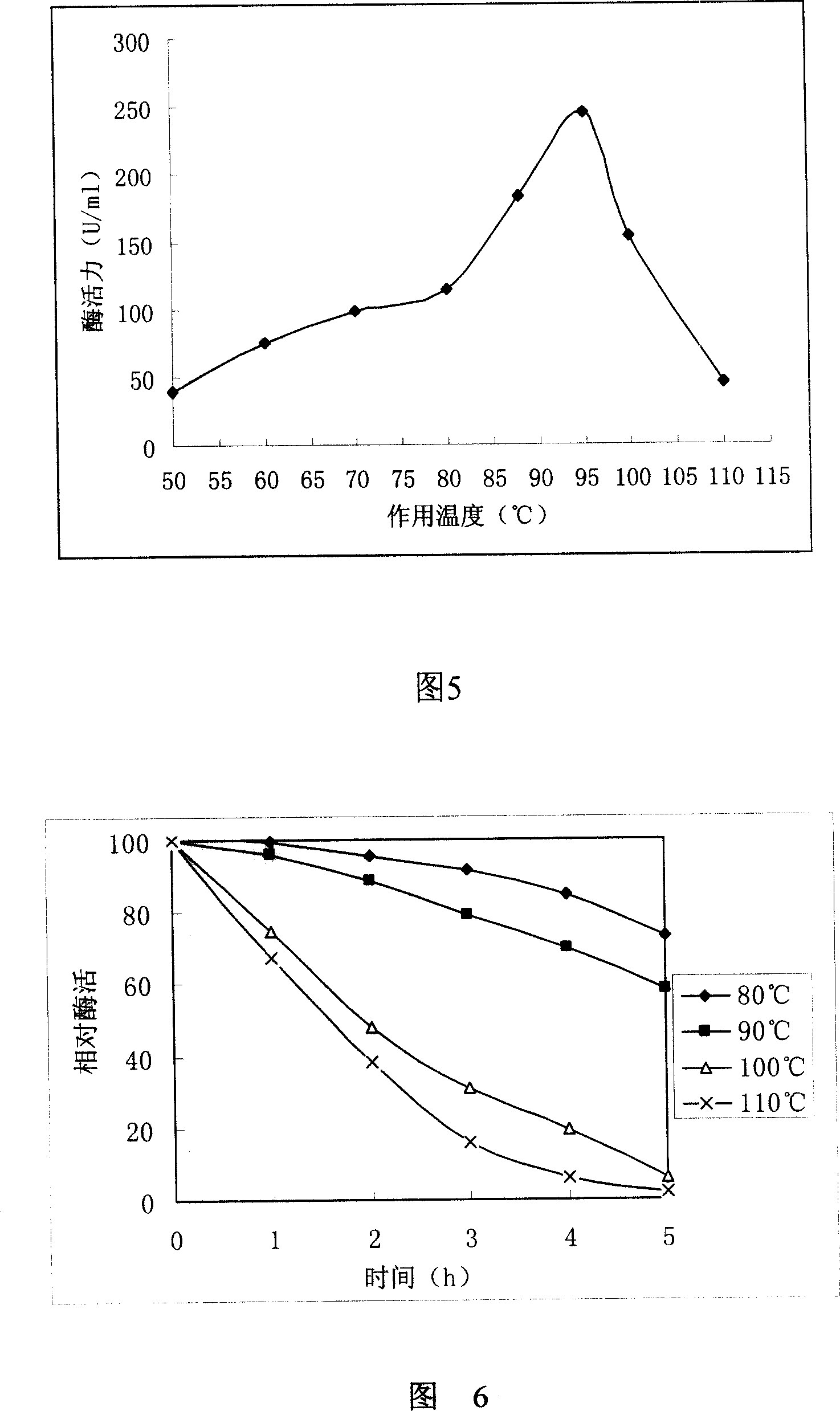

[0067] Example 3. The high temperature-resistant acid alpha-amylase produced by the method described in embodiment 2, described high temperature resistant acid alpha-amylase has the following characteristics:

[0068] (1) The optimum action temperature of the enzyme is 95°C, and the enzyme has good thermal stability. The enzyme keeps the enzyme activity unchanged at 90°C for 2 hours, 75% of the enzyme activity at 100°C for 1 hour, and 110°C for 2 hours. 40% enzyme activity, is a high temperature resistant α-amylase;

[0069] (2) The optimal pH of the enzyme is 5.0, and the most stable pH of the enzyme is 5.5, which is an acid α-amylase;

[0070] (3)K + 、Sr 2+ , Mg 2+ 、Na + It has a certain promoting effect on the activity of α-amylase; Cu 2+ , Pb 2+ , Hg 2+ , Zn 2+ Strong inhibitory effect on α-amylase;

[0071] (4) IAA, PMSF, SDS have a strong inhibitory effect on the enzyme, EDTA-Na and 2-hydroxyethanol have an inhibitory effect on the enzyme activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com