Process for reifining Nedaplatin

A technology for nedaplatin and refined products, applied in the field of refining nedaplatin, can solve the problems of low purity and low yield in high performance liquid chromatography analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

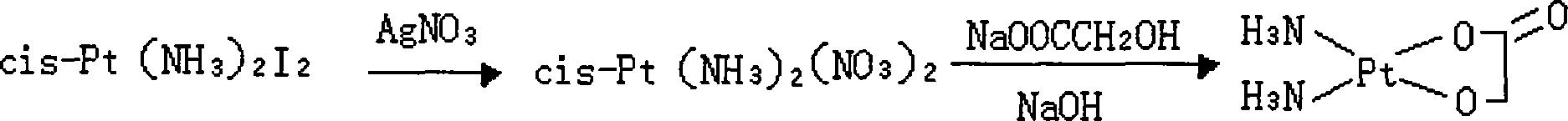

Method used

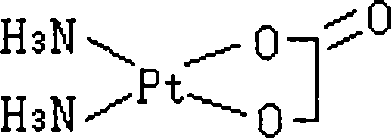

Image

Examples

example 1

[0018] Dissolve 10 g of nedaplatin containing 150 ppm of silver in 800 ml of hot water at 60°C, add about 1.5 mg of KI, stir for 10 min, and filter with a 0.22 μm filter membrane. After stirring, add 1200ml of ethanol next time, cool to -18°C and crystallize for 15 hours, filter the precipitated solid, and vacuum dry at 50°C for 6 hours to obtain the refined product of Nida Platinum 8.2, yield: 82%; no flame atomic absorption spectrometry analysis, silver The content is less than 5ppm, and the high performance liquid chromatography analysis shows that the content is greater than 99%.

example 2

[0020] Dissolve 10 g of nedaplatin containing 150 ppm of silver in 500 ml of hot water at 70°C, add about 1.5 mg of KI, stir for 10 min, and filter with a 0.22 μm filter membrane. After stirring, add 1000ml of ethanol next time, cool to -18°C to crystallize for 15 hours, filter the precipitated solid, and dry it in vacuum at 50°C for 6 hours to obtain the refined product of Nida Platinum 8.6, yield: 86%; no flame atomic absorption spectrometry analysis, silver The content is less than 5ppm, and the high performance liquid chromatography analysis shows that the content is greater than 99%.

example 3

[0022] Dissolve 10 g of nedaplatin containing 150 ppm of silver in 500 ml of hot water at 45°C, add about 1.5 mg of KI, stir for 10 min, and filter with a 0.22 μm filter membrane. After stirring, add 1000ml of ethanol next time, cool to -18°C for crystallization for 15 hours, filter the precipitated solid, and vacuum dry at 50°C for 6 hours to obtain the refined product of Nida Platinum 8.3, yield: 83%; no flame atomic absorption spectrometry analysis, silver The content is less than 5ppm, and the high performance liquid chromatography analysis shows that the content is greater than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com