Container in automobile

A technology for containers and vehicles, applied to pressure vessels, buses, outer walls of container structures, etc., can solve the problems of negative effects on dimensional stability, increased risk of warping, and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

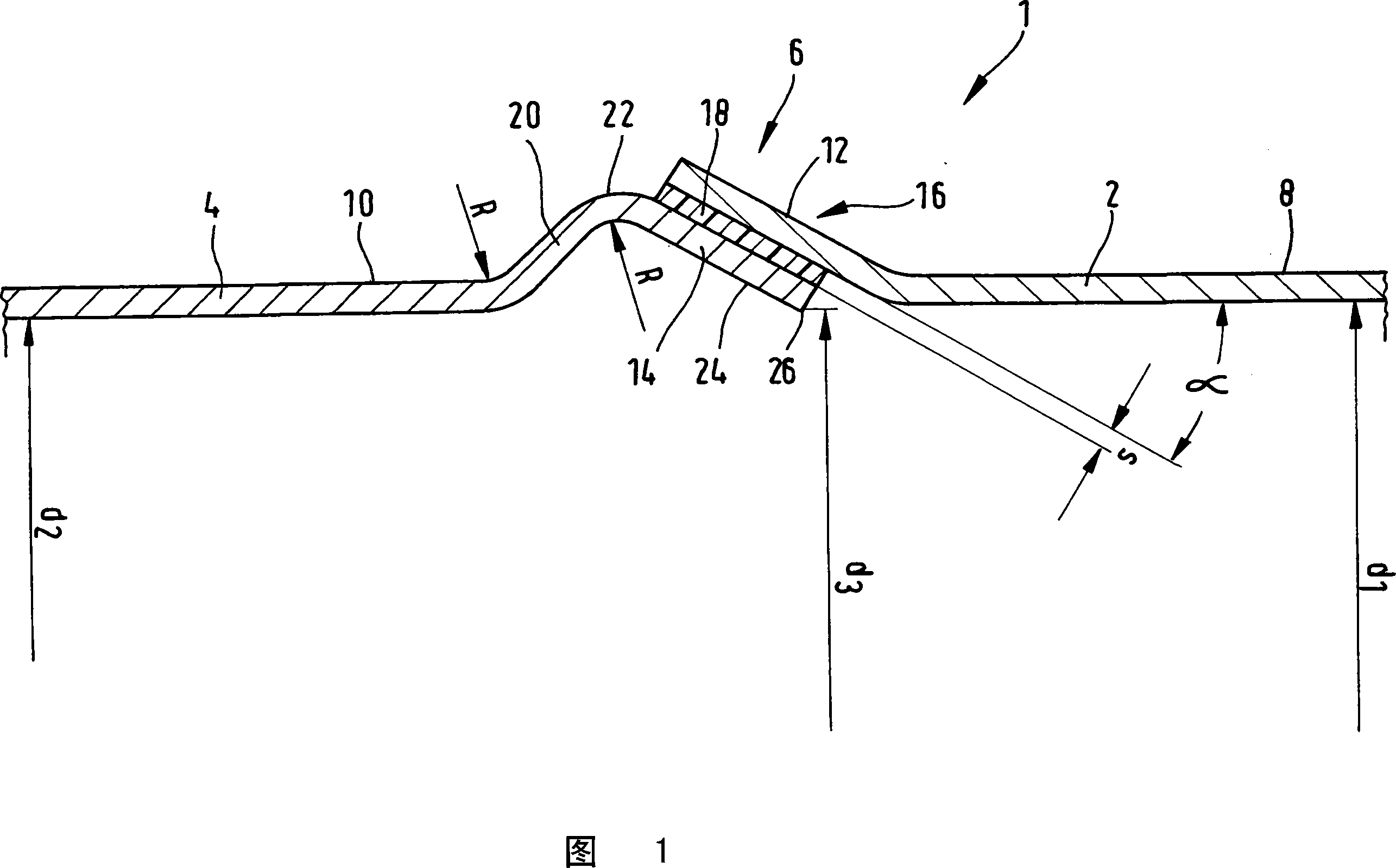

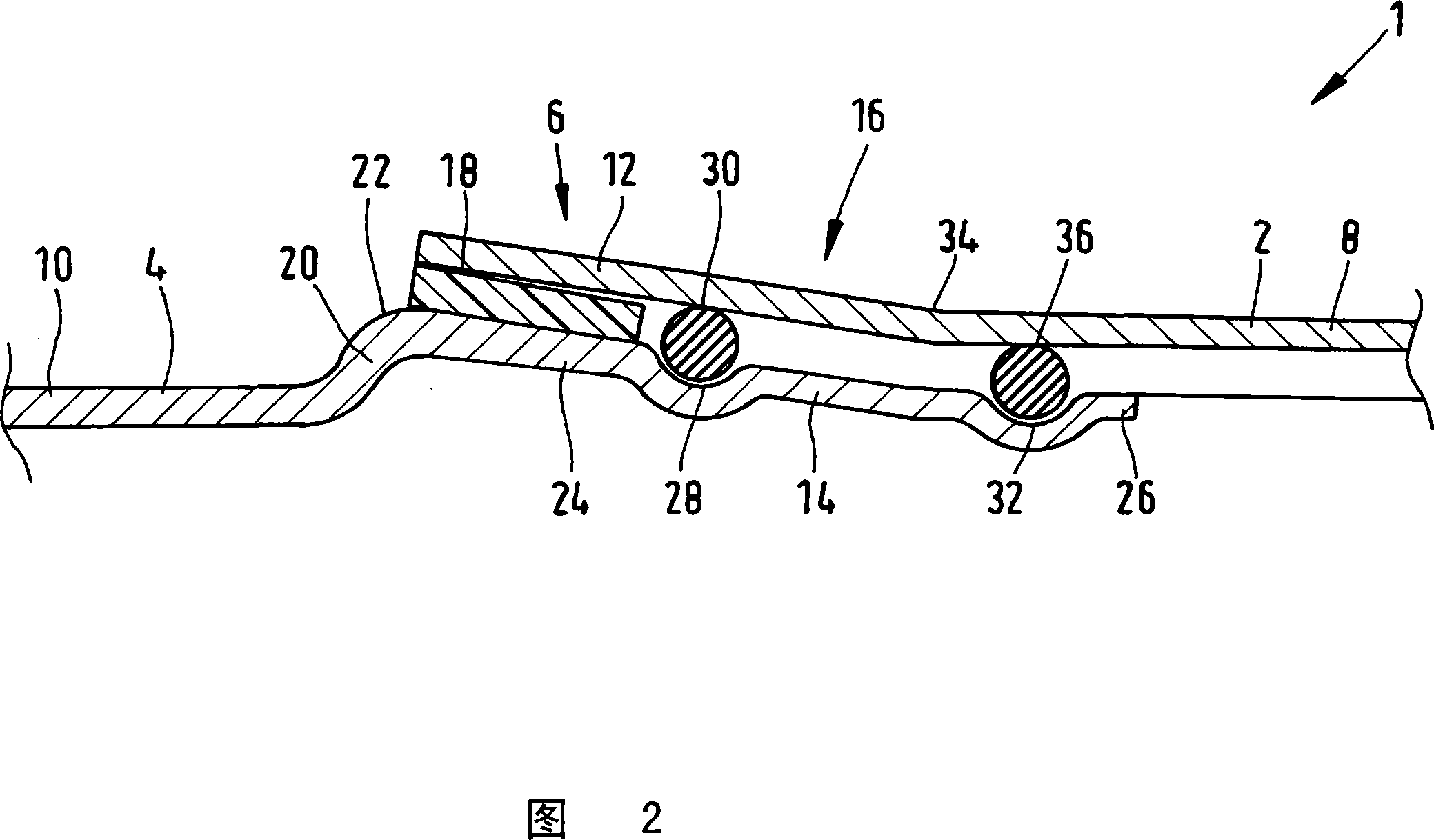

[0019] The container shown only in section in FIG. 1 and marked as a whole with 1 is preferably used as a compressed air container for storing compressed air for a compressed air brake system of a truck. Alternatively, the container can be used to store compressed air for any compressed air user in the vehicle, for example for pneumatic door operators, for compressed air springs or for other pneumatic vehicle devices or vehicle mechanisms.

[0020] As shown in FIG. 1 , a compressed air container 1 is assembled, for example, from two container halves 2 , 4 of equal size, preferably with a circular cross section, which are joined to each other by their common connecting region 6 . Tightly connected. The container halves 2, 4 are preferably produced from a steel sheet provided with an anti-corrosion coating on the inner surface, which is formed into a cup-like shape by deformation, for example by deep drawing. This means that each of the container halves 2 , 4 consists of a bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com