Process and apparatus for producing packing plastic material

A packaging material and production process technology, which is applied in the production process and equipment field of all-plastic packaging materials, can solve problems such as insufficient composite strength, low yield rate, and poor appearance, and achieve the effects of recycling, reducing waste, and saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

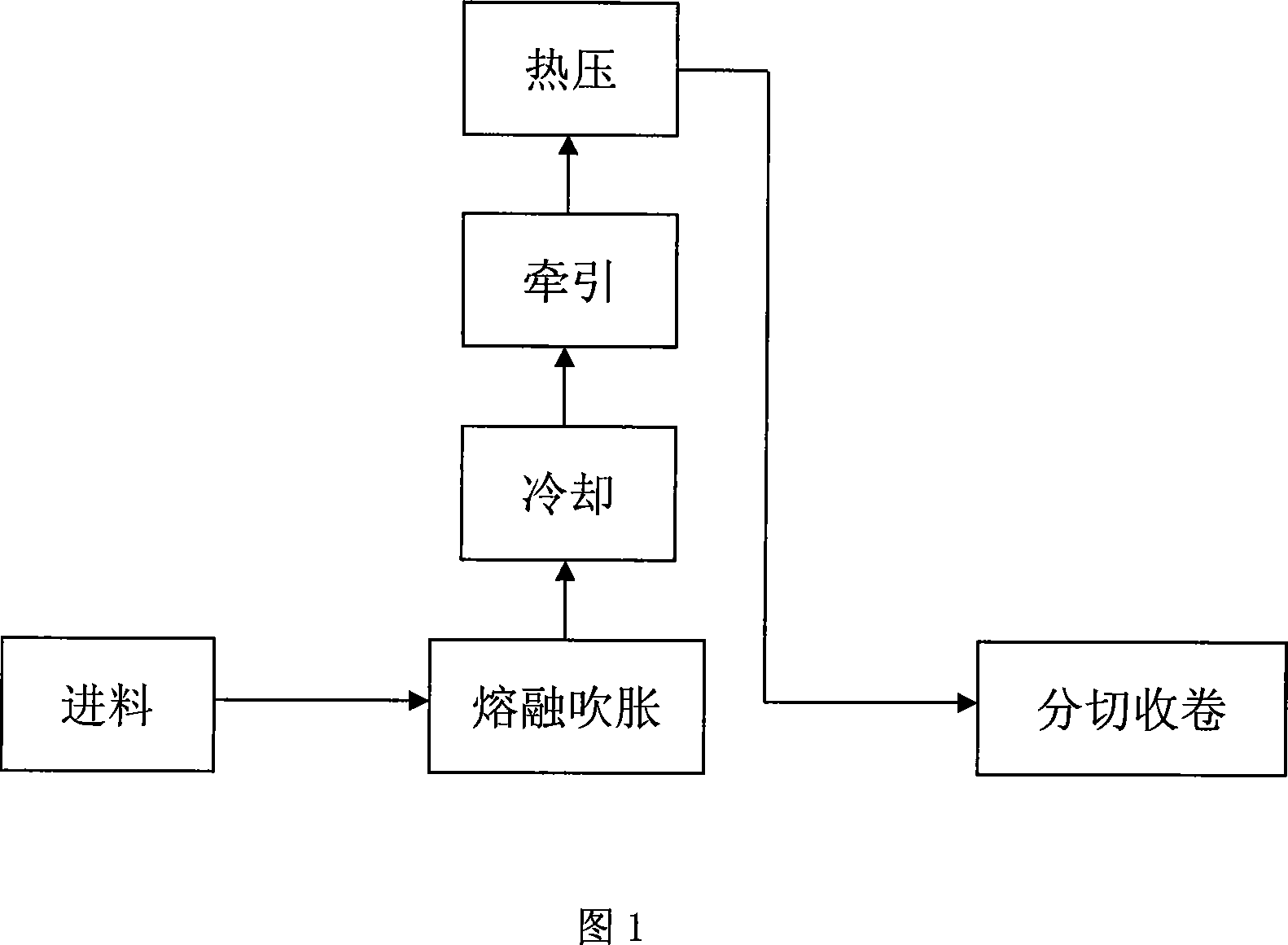

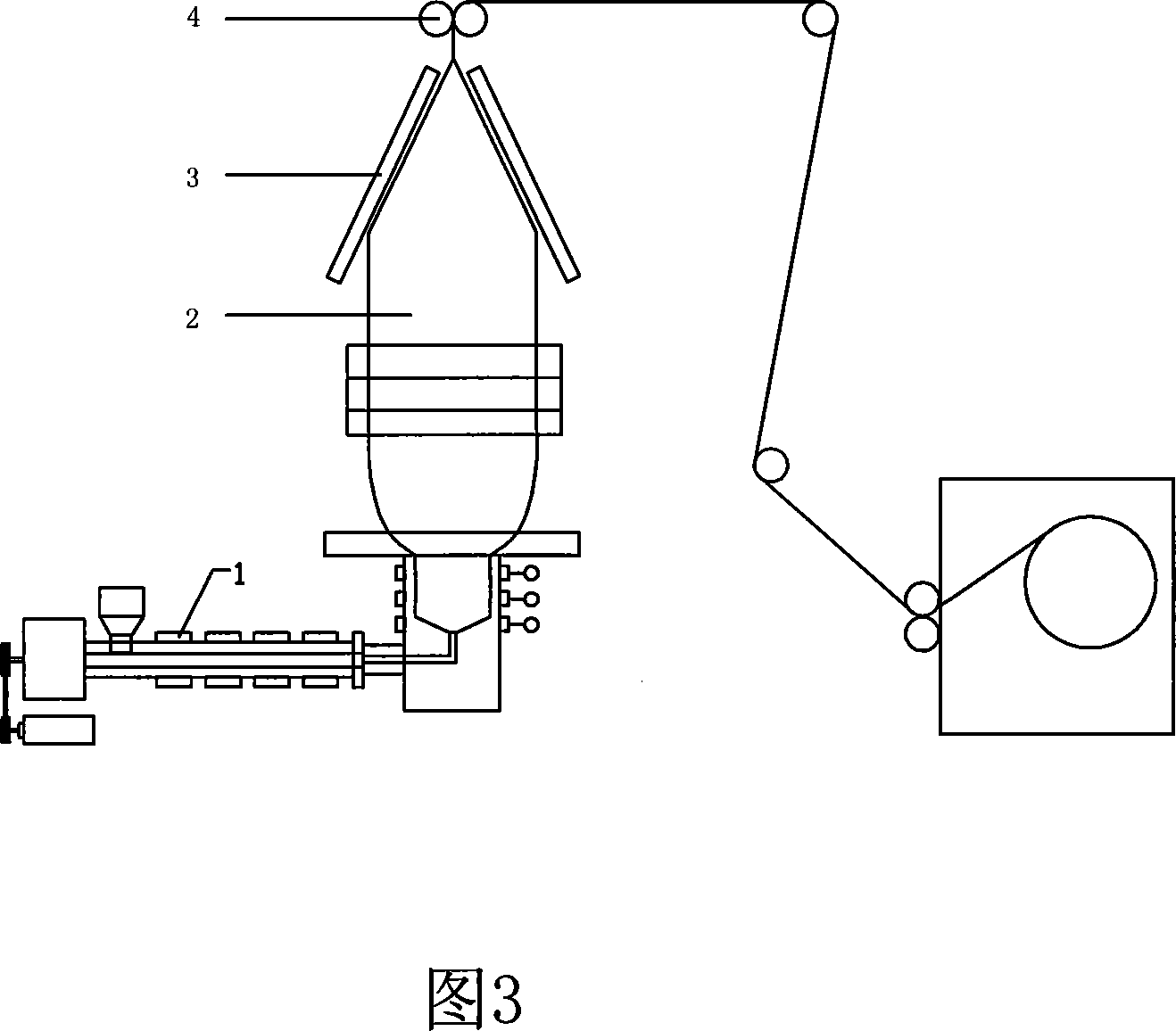

[0029] As shown in Figure 3, the six-layer co-extrusion non-barrier sheet produced by the method of the present invention is processed by a three-layer co-extrusion blown film machine with additional hot pressing rollers.

[0030] The specific manufacturing process is as follows:

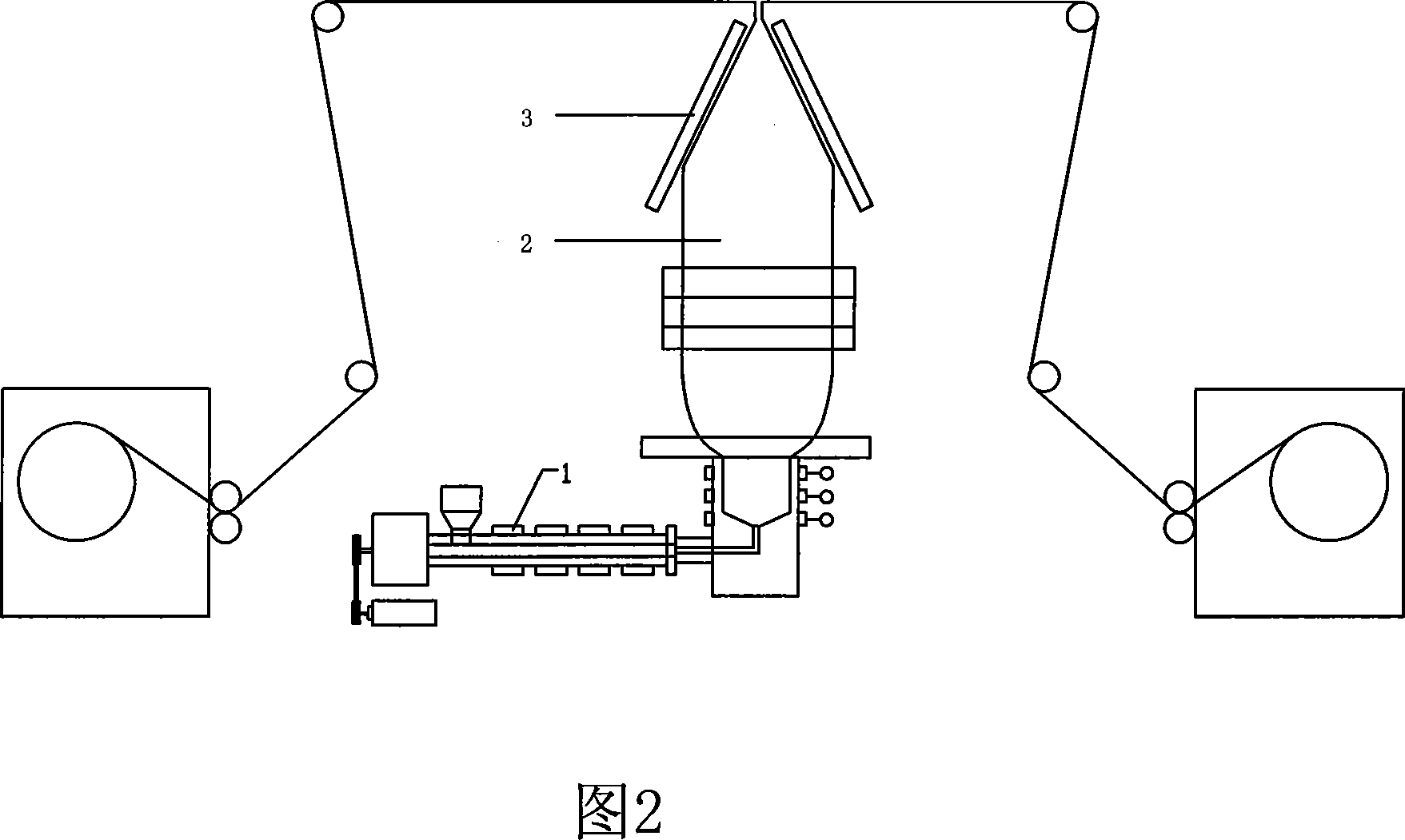

[0031] As shown in Figure 1 and Figure 3, in the existing three-layer co-extrusion blown film equipment (Figure 2), the required various resins and raw materials are weighed according to the set ratio after being weighed through the automatic metering hopper After entering the screw 1, it is heated and melted and blown out from the die head. The blown film bubble 2 is drawn by the herringbone frame 3 to form two co-extruded three-layer films with the inner layers facing each other. Afterwards, make the three-layer film that two inner layers are opposite pass through hot pressing roll 4 simultaneously, the temperature of hot pressing roll 4 is 50 ℃, guarantee good compound strength between the bondin...

Embodiment 2

[0033] As shown in Fig. 4, the fourteen-layer co-extrusion non-barrier sheet produced by the method of the present invention is processed by a seven-layer co-extrusion blown film machine with additional hot pressing rollers.

[0034] The specific manufacturing process is as follows:

[0035] As shown in Figure 1 and Figure 3, in the existing seven-layer co-extrusion blown film equipment (Figure 2), the required various resins and raw materials are weighed according to the set ratio after being weighed through the automatic metering hopper After entering the screw 1, it is heated and melted and blown out from the die head. The blown film bubble 2 is drawn by the herringbone frame 3 to form two co-extruded seven-layer films with opposite inner layers. Thereafter, the seven-layer film opposite to the two inner layers is passed through the hot pressing roller 4 at the same time, and the temperature of the hot pressing roller 4 is 80° C. to ensure good composite strength between th...

Embodiment 3

[0037] The 26-layer co-extrusion barrier-free sheet produced by the method of the present invention is processed by a 13-layer co-extrusion film blowing machine with additional hot pressing rollers.

[0038] The specific manufacturing process is as follows:

[0039] As shown in Figures 1 and 3, in the existing thirteen-layer co-extrusion blown film equipment (as shown in Figure 2), the required various resins and raw materials are weighed through the automatic metering hopper and then weighed according to the set formula. The ratio enters the screw 1, and after being heated and melted, it is blown out from the die head, and the blown film bubble 2 is drawn by the herringbone frame 3 to form two co-extruded thirteen-layer films with the inner layers facing each other. Thereafter, two thirteen-layer films with opposite inner layers are passed through the hot pressing roller 4 at the same time, and the temperature of the hot pressing roller 4 is 100° C. to ensure good composite s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com