Inline process type coating apparatus

A coating device and on-line technology, applied in the direction of spraying devices, spraying devices, devices for coating liquid on the surface, etc., can solve the problems of reduced production efficiency, complicated operation, excessive time, etc., to prevent bad coating, Ease of coating operation and improvement of coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings, and will be described within the range in which those skilled in the art can practice the embodiments of the present invention.

[0036] In addition, since the embodiments of the present invention can be implemented in various forms, the scope of claims of the present invention is not limited to the scope of the following embodiments.

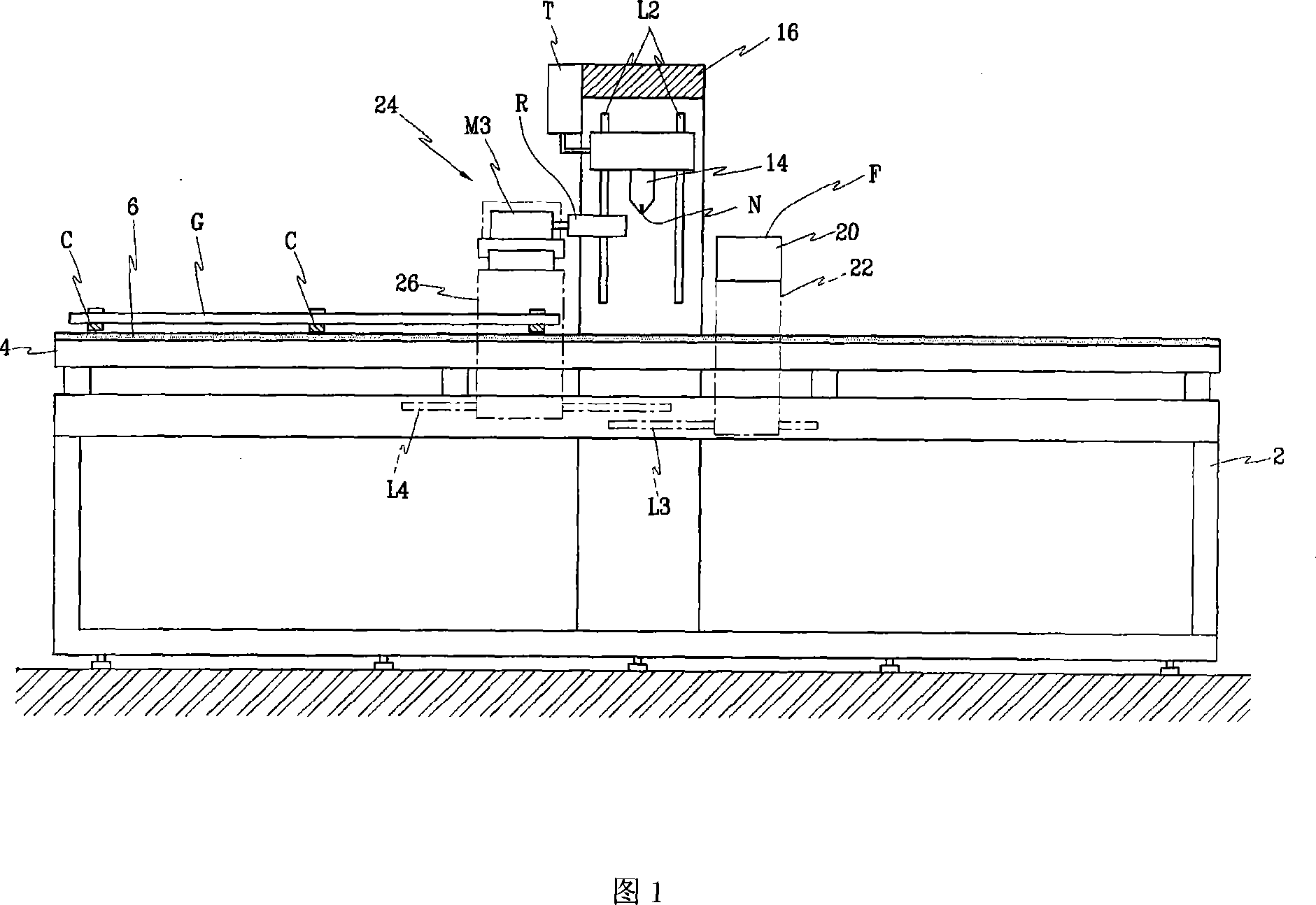

[0037] Fig. 1 is a front view illustrating the overall structure of an in-line coating device according to an embodiment of the present invention, and the symbol 2 in the figure refers to a working platform.

[0038] The working platform 2 has a working surface 4 , and the size of the working surface 4 is suitable for coating the photoresist W in an on-line manner during the conveyance of the substrate G.

[0039] The working platform 2 may use a metal bracket formed by welding or connecting metal steel with screws, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com