Fluidized-bed coating machine

A technology of coating machine and fluidized bed, applied in the direction of chemical instruments and methods, chemical/physical processes, and methods of granulating raw materials, etc., can solve problems such as waste, affecting the disintegration and dissolution of active ingredients, and achieve convenience and ease. Release, firm adhesion, and improve the effect of true sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

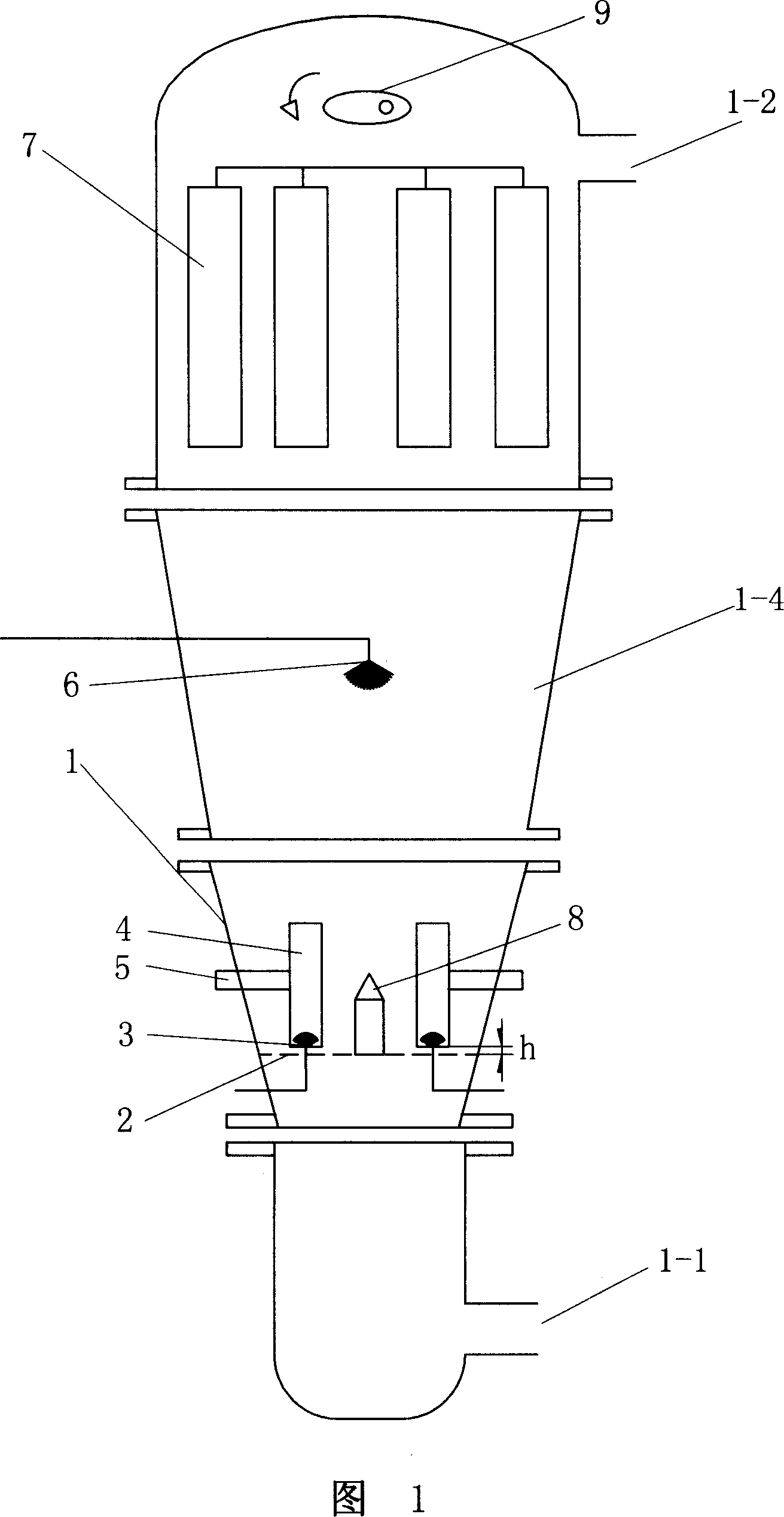

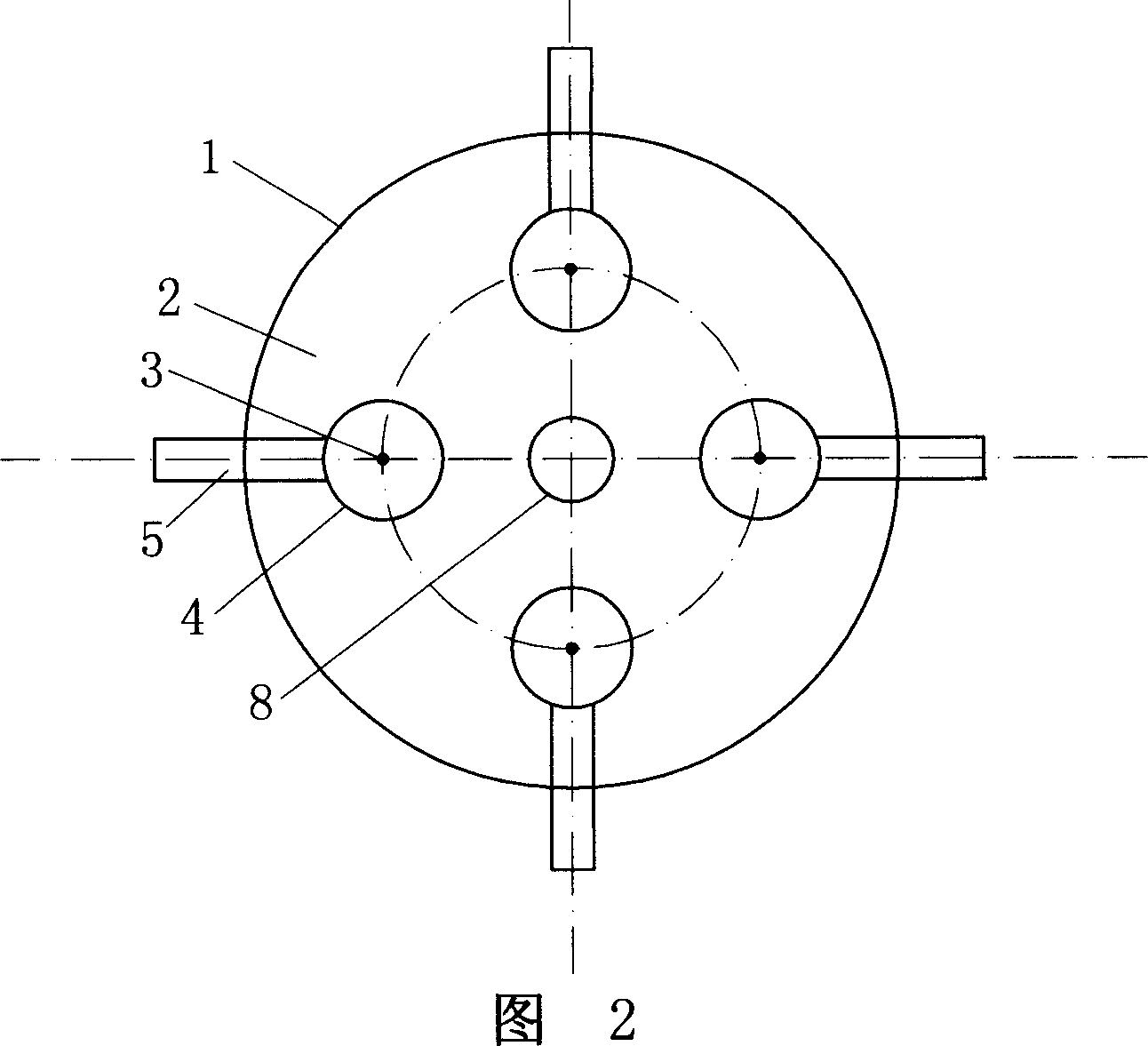

[0023] See Figure 1 and Figure 2. In this example, granulation and coating are completed in the same tank, which is especially suitable for the processing of slow-release and controlled-release pharmaceutical products. It includes a tank body 1, the tank body 1 has a dry air inlet 1-1 and an air outlet 1-2, the tank body 1 is provided with an air flow distribution plate 2, and the fluidization chamber 1-4 of the tank body 1 is in the shape of an inverted cone Form the expansion chamber. A cloth bag filter 7 is provided on the upper part of the tank body 1, and an eccentric rapping device 9 is provided above the filter 7. Filters and eccentric rapping devices are commercially available.

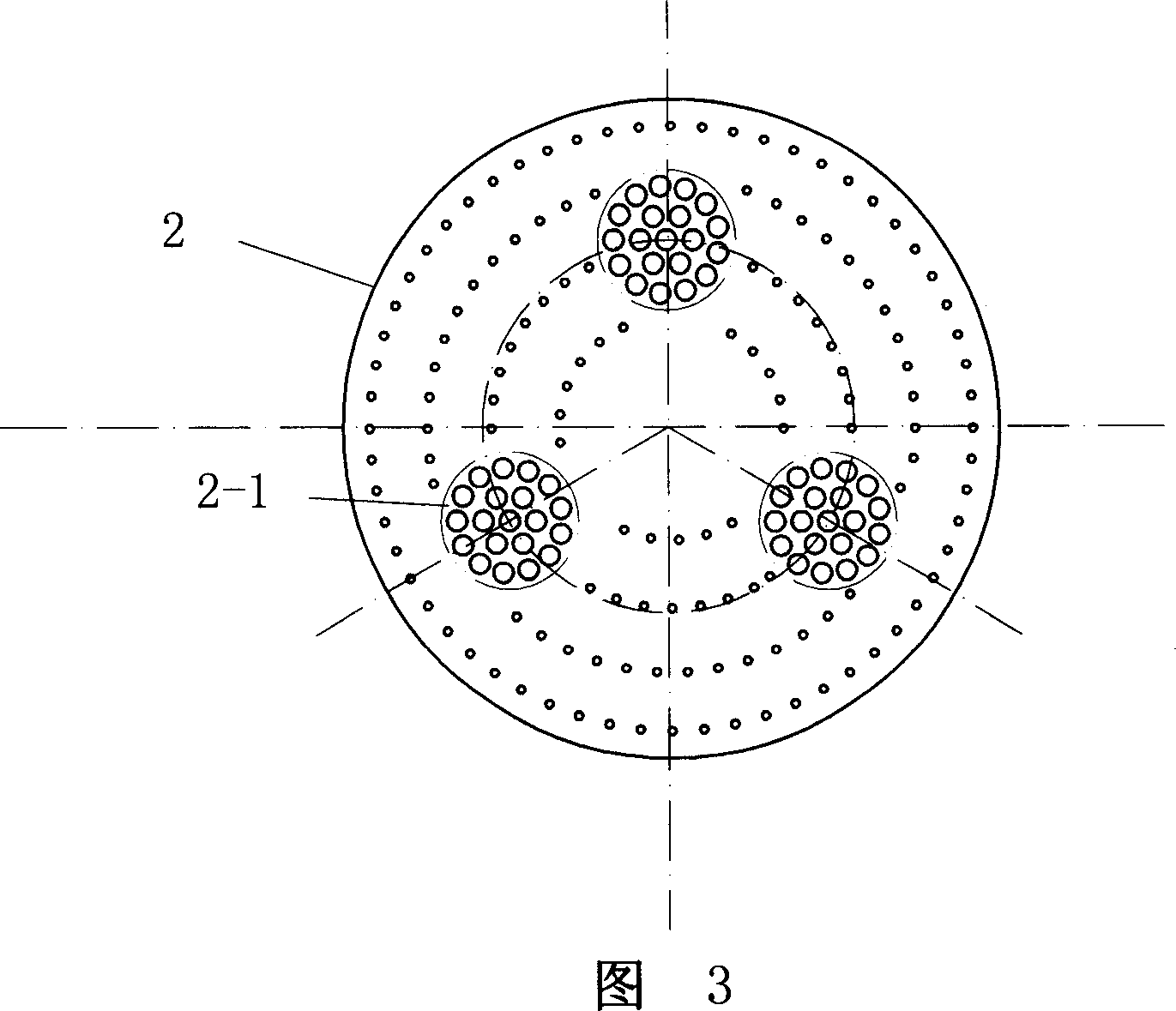

[0024] Referring to FIG. 3 , at least two large-hole areas 2-1 are provided on the airflow distribution plate 2, and generally 3-6 large-hole areas 2-1 can be optionally provided. The large hole areas 2-1 are evenly distributed on the same circumference, that is, the distances between the ce...

Embodiment 2

[0027] As shown in FIG. 3 , the air distribution plate 2 of this embodiment is provided with 3 large hole areas, and correspondingly, 3 guide cylinders are provided. All the other are identical with embodiment 1.

[0028] The embodiment in which 5 or 6 large hole regions are provided on the air distribution plate 2 can be made on the basis of the above description for those of ordinary skill in the art.

Embodiment 3

[0030] See Fig. 5, present embodiment is only coating machine. It includes a tank body 1, the tank body 1 has a dry air inlet 1-1 and an air outlet 1-2, the tank body 1 is provided with an air flow distribution plate 2, and the fluidization chamber 1-4 of the tank body 1 is in the shape of an inverted cone extension room. The upper part in the tank body 1 is provided with a screen filter 7 . The large hole area 2-1 on the airflow distribution plate 2 is set as required, as long as the opening ratio of the large hole area 2-1 is at least 65%. Above the air distribution plate 2 and facing each large hole area 2-1, there is a guide cylinder 4, and there is a gap h between the bottom surface of the guide cylinder and the air distribution plate, and the gap h is 3-15 mm. The center of the air distribution plate 2 is provided with a protrusion 8 whose head is a cone. A coating nozzle 3 is arranged corresponding to each guide cylinder 4, and the coating nozzle 3 protrudes from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com