Glassy carbon electrode modified electrochemical detection method for diethylstilbestrol

A glassy carbon electrode, diethylstilbestrol technology, applied in the field of electrochemical analysis, can solve the problems of high detection limit, unable to meet the minimum detection limit of hexene residues, poor repeatability, etc. Human, reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment 1 is implemented under the following conditions of implementation and technical requirements:

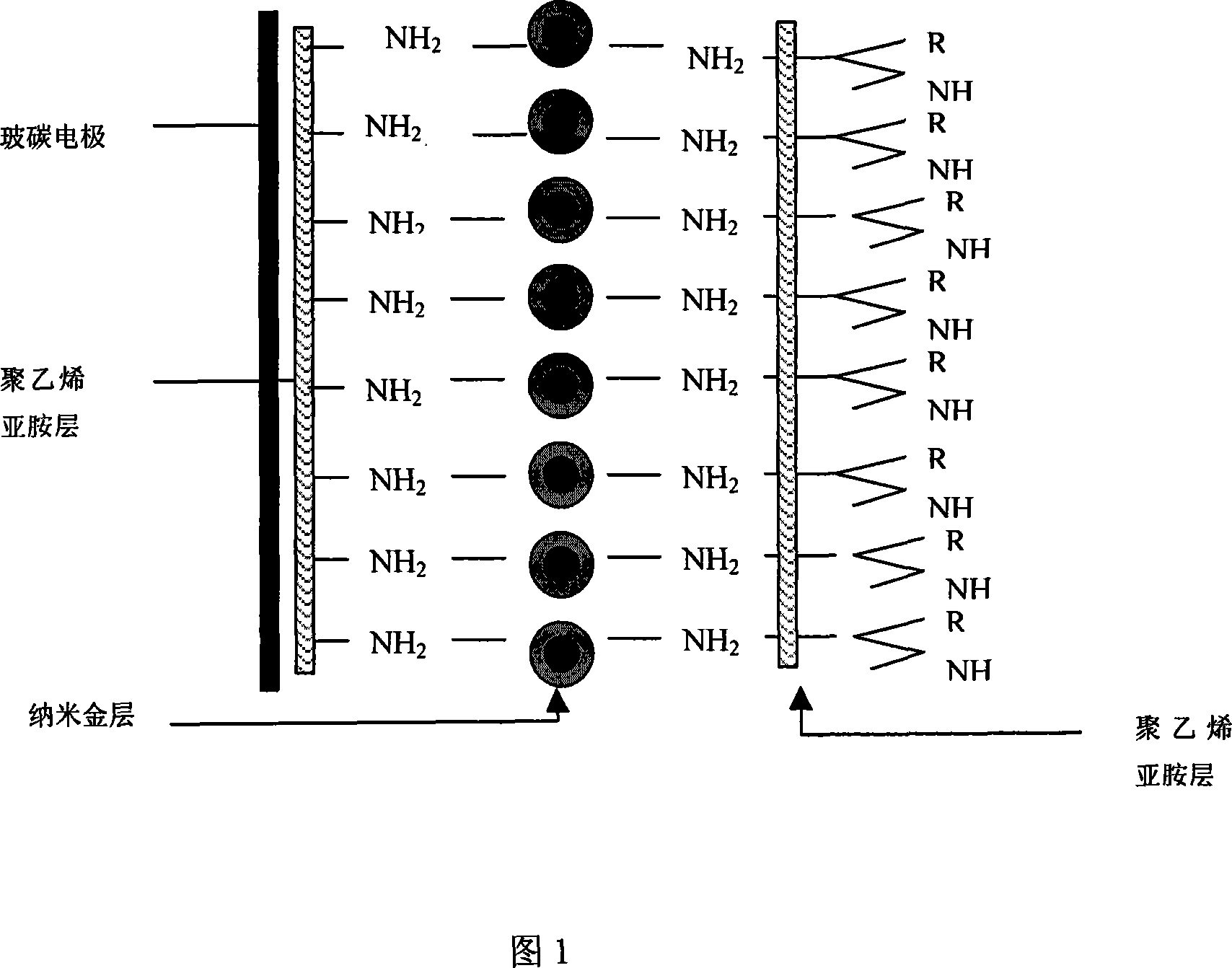

[0038] (1) Preparation of polyethyleneimine-nanogold modified electrode

[0039] (1) Electrode pretreatment:

[0040] First, the glassy carbon electrode is used on the suede with TiO 2 The nano-powder is polished in the shape of "8" to make it into a mirror surface, rinsed with distilled water, and then cleaned with ultrasonic waves for 10 minutes. Then put the cleaned glassy carbon electrode into nitric acid solution and acetone solution with a volume ratio of 1:1 and soak for 3 minutes respectively, and rinse the electrode with distilled water. Finally, the electrodes were dried under infrared lamps.

[0041] (2) Preparation of nano-gold colloidal particles: first add 0.5 ml of 1% chloroauric acid solution to a large beaker with 200 ml of distilled water. Then place the beaker on the electric stove and bring to a boil over high heat. Use a pipette gun t...

Embodiment 2

[0056] This embodiment 2 is implemented under the following conditions of implementation and technical requirements:

[0057] (1) Preparation of polyethyleneimine-nanogold modified electrode

[0058] (1) Electrode pretreatment:

[0059] Firstly, the process of grinding the glassy carbon electrode on the suede and rinsing with distilled water is the same as in Example 1. Then ultrasonic cleaning was used for 30 minutes, and then the cleaned glassy carbon electrode was put into nitric acid and acetone solutions with a volume ratio of 1:1 and soaked for 15 minutes respectively, and the electrode was rinsed with distilled water. Finally, the electrode was dried naturally in the air.

[0060] (2) Preparation of nano-gold colloidal particles: first add 1.0 ml of 1% chloroauric acid solution into a large beaker with 200 ml of distilled water. Then place the beaker on the electric stove and bring to a boil over high heat. Use a pipette gun to add 2.0ml of freshly prepared 1% triso...

Embodiment 3

[0070] This embodiment 3 is implemented under the following conditions of implementation and technical requirements:

[0071] (1) Preparation of polyethyleneimine-nanogold modified electrode

[0072] (1) Electrode pretreatment:

[0073] Firstly, the process of grinding the glassy carbon electrode on the suede and rinsing with distilled water is the same as in Example 1. Then ultrasonic cleaning was used for 20 minutes, and then the cleaned glassy carbon electrode was put into nitric acid and acetone solutions with a volume ratio of 1:1 and soaked for 9 minutes respectively, and the electrode was rinsed with distilled water. Finally, the electrodes were dried naturally in the air.

[0074] (2) Preparation of nano-gold colloidal particles: first add 0.75ml of 1% chloroauric acid solution into a large beaker with 200ml of distilled water. Then place the beaker on the electric stove and bring to a boil over high heat. Use a pipette gun to add 1.0ml of freshly prepared 1% triso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com