Freeze-dryer water-trapping system

A technology of freeze dryer and water catcher, which is applied in the direction of drying, drying solid materials, and drying solid materials without heating. It can solve the problems of increased manufacturing cost, energy waste, and small pipe diameter, so as to improve product quality, Effect of reducing energy consumption and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

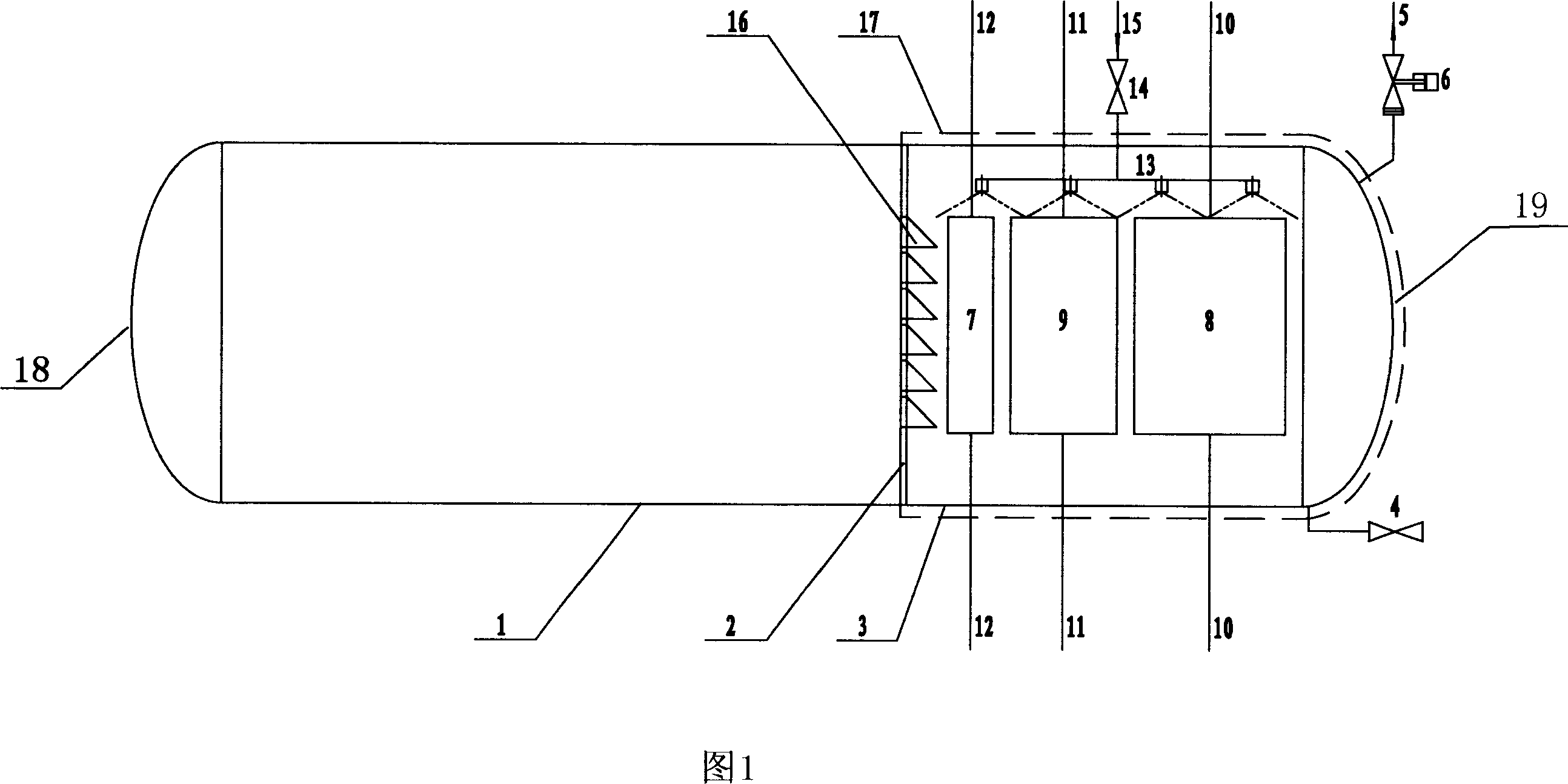

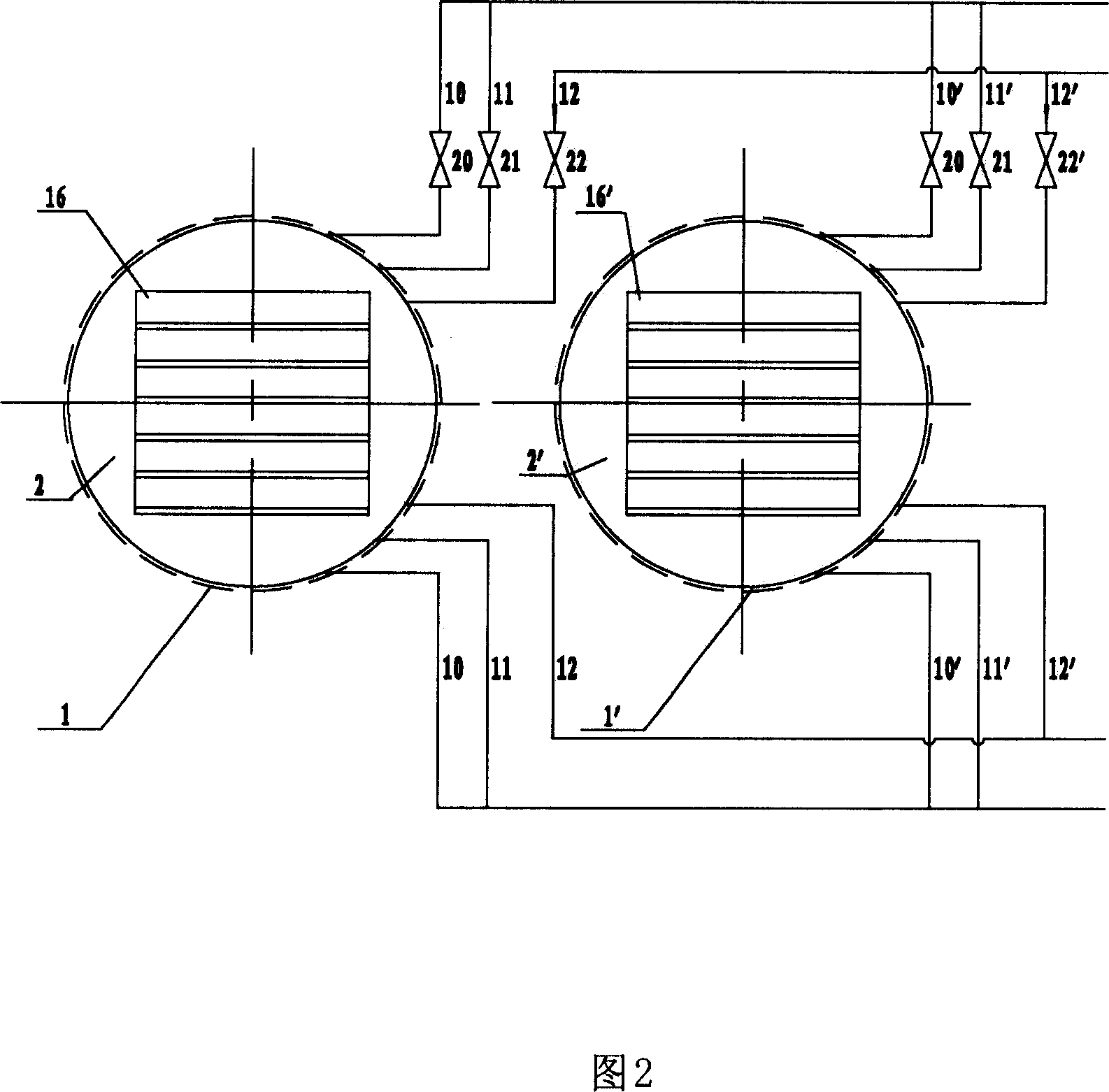

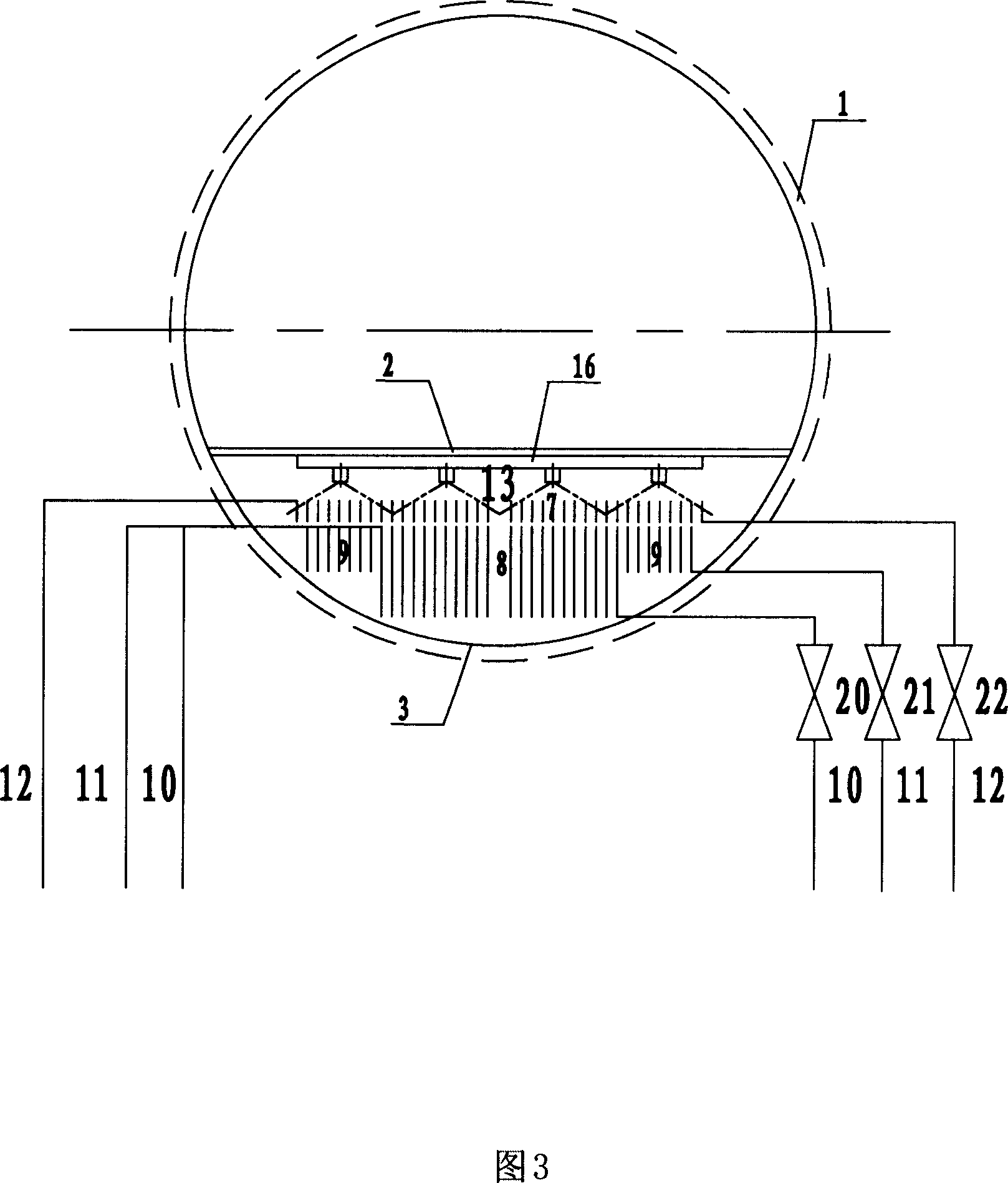

[0036] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0037] As shown in Figure 1, it is a diagram of the water catch structure system of a freeze dryer, which is a rear-mounted internal water catch system, including a water catcher and a defrosting device. The water catchers in this embodiment are 3, including a large water catcher 8 , middle water catcher 9, small water catcher 7. The area size ratio of each water catcher is distributed according to the usage requirements. Drying bin 1 is separated by dividing plate 2 as the cold trap bin body 3 of each water catcher from the extended section of one end of door 18; The louvers inclined inside, the louvers can separate the hot temperature field of the drying chamber 1 from the cold temperature field of the water trap, prevent energy offset caused by radiation heat transfer, and prevent spray water from splashing into the drying chamber 1 during defrosting. It is suita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com