Reused process for waste water in calcium hydrogen orthophosphate production

A calcium hydrogen phosphate and waste water technology, applied in the fields of phosphorus compounds, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of water resource waste, high cost, environmental pollution, etc., to solve the discharge problem, reduce The effect of dosage and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

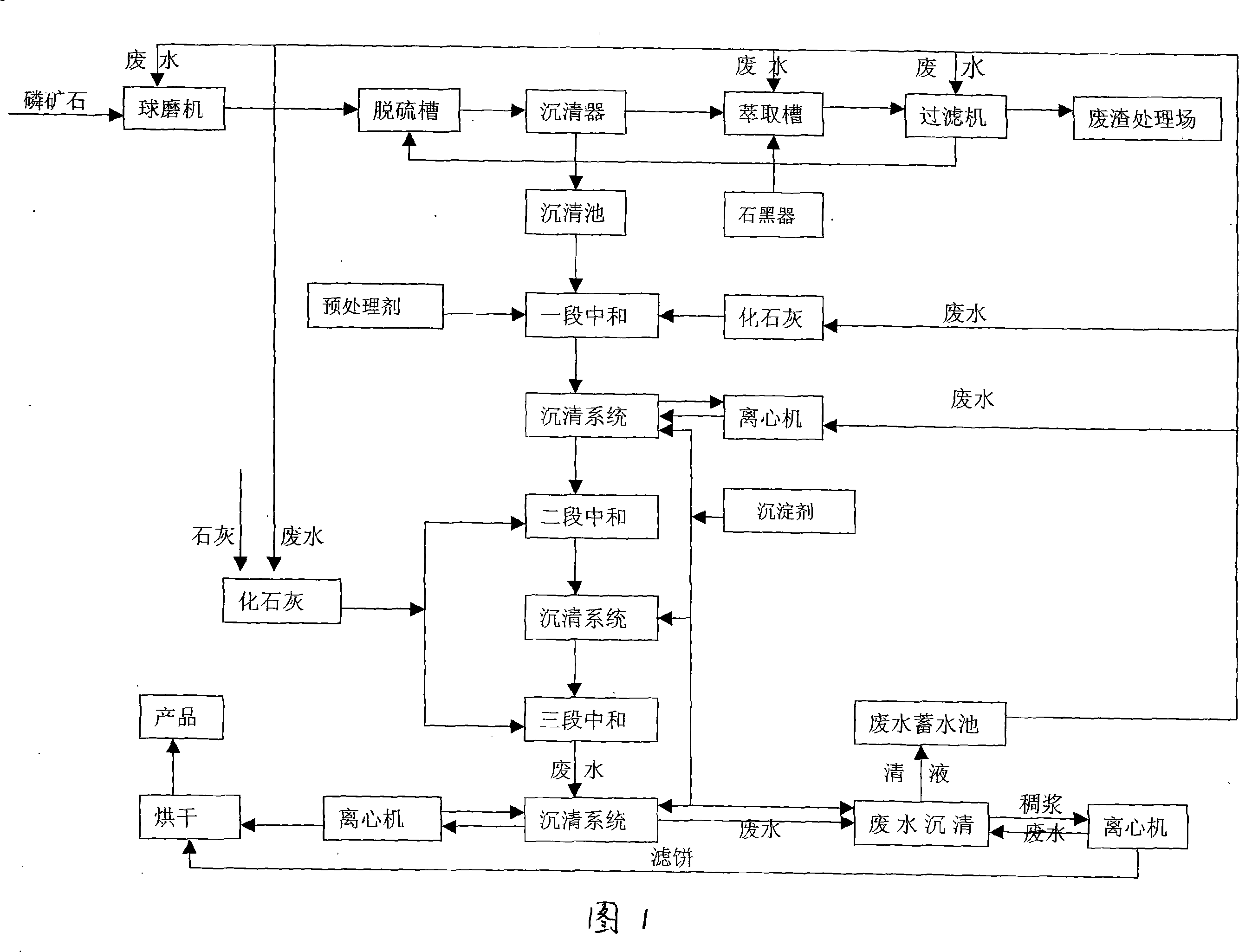

Image

Examples

Embodiment Construction

[0015] The phosphate rock is crushed into a phosphate rock slurry with a water content of 30% by a ball mill. After adding sulfuric acid, it is settled and extracted to obtain wet process phosphoric acid. Before a stage of neutralization, the phosphoric acid is pretreated to remove impurities, that is, the Add 10Kg of sodium sulfate, 30Kg of diatomaceous earth, and 2Kg of ammonia hydroxyl complexing agent to rice phosphoric acid, then add 100-300Kg of lime milk, and control the pH value of the thick slurry at 2.0-2.5. A polyacrylamide precipitating agent accounting for 1% by weight is added to the thick slurry. The slurry separated by sedimentation and centrifugation can be used as phosphate fertilizer. After adding lime milk to the first-stage sedimentation water, the second-stage neutralization is carried out. At the same time, the pH value of the thick slurry is controlled at 2.5-3.5, and the thick slurry can be added 1% by weight polyacrylamide precipitation agent. The th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com