Semiconductor laser self-mixing effect based high reflectivity measurement method

A technology with high reflectivity and measurement method, which is applied in the field of measuring optical component parameters, can solve the problems of poor pulse laser beam quality, high cost of pulse laser system, and high system alignment requirements, and achieve high-precision determination of reflectivity and large measurement range , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

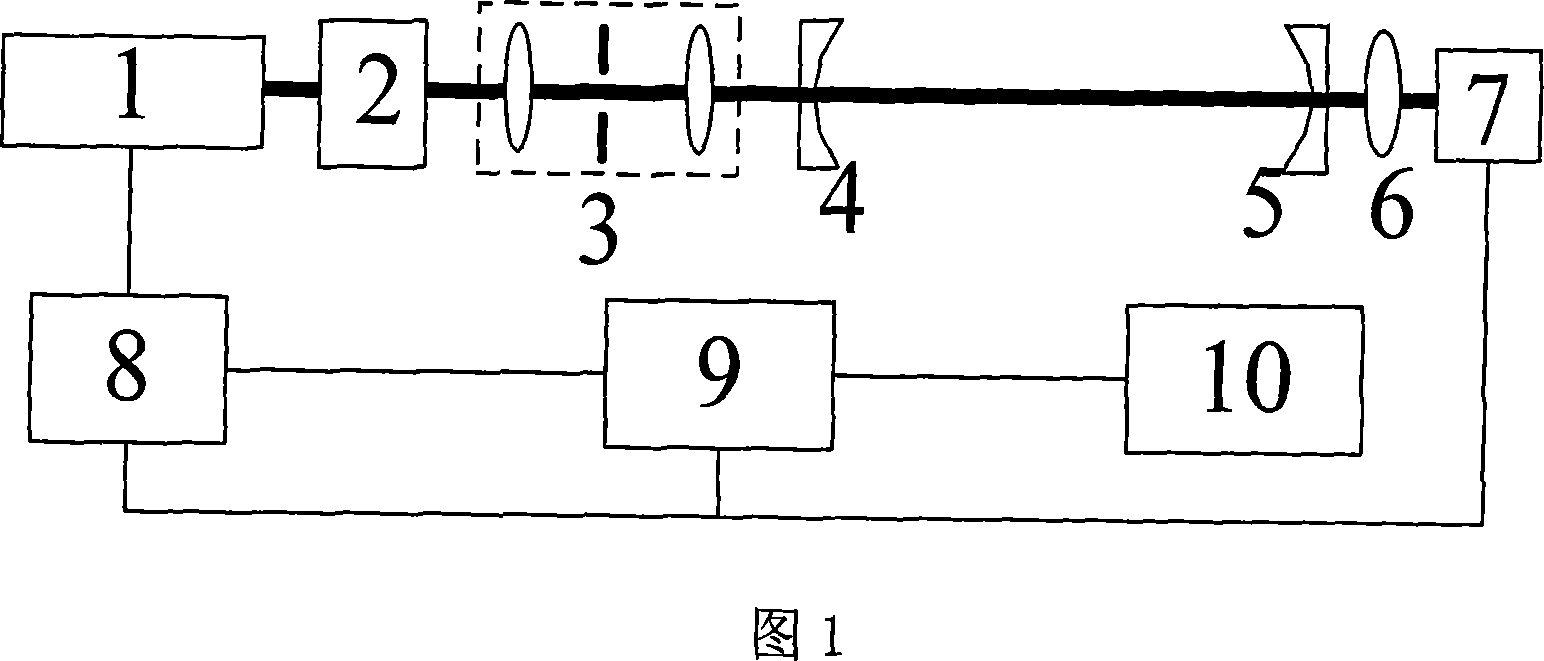

[0027] As shown in Figure 1, the measuring device of the present invention consists of a light source 1, an iris diaphragm 2, a spatial filter and a telescopic system 3, a plano-concave high mirror 4,5, a converging lens 6, a detector 7, and a trigger switch circuit 8 , an oscilloscope or a data acquisition card 9 and a computer 10. The thick line in the figure indicates the optical path, and the thin line indicates the connection of the signal line. The detector 6 generally adopts a photodiode or a photomultiplier tube detector.

[0028] The light source 1 is a continuous semiconductor laser. The iris diaphragm 2 is used to control the intensity of the backward feedback light, and a linear polarizer, an attenuation film or an optical isolator can also be used, or the pitch of the first cavity mirror can be adjusted, or the distance between the semiconductor laser and the first cavity mirror can be adjusted. The distance between them along the direction of the optical path m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com