Building method for plant residue base ecological slope protection

A technology of ecological slope protection and construction method, which is applied in the fields of botanical equipment and methods, infrastructure engineering, excavation, etc., can solve the problems of polluting the atmospheric environment, environmental hazards, waste of resources, etc., and achieves a simple production process, environmental protection and safety in the production process. Reduce the effect of impact washout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

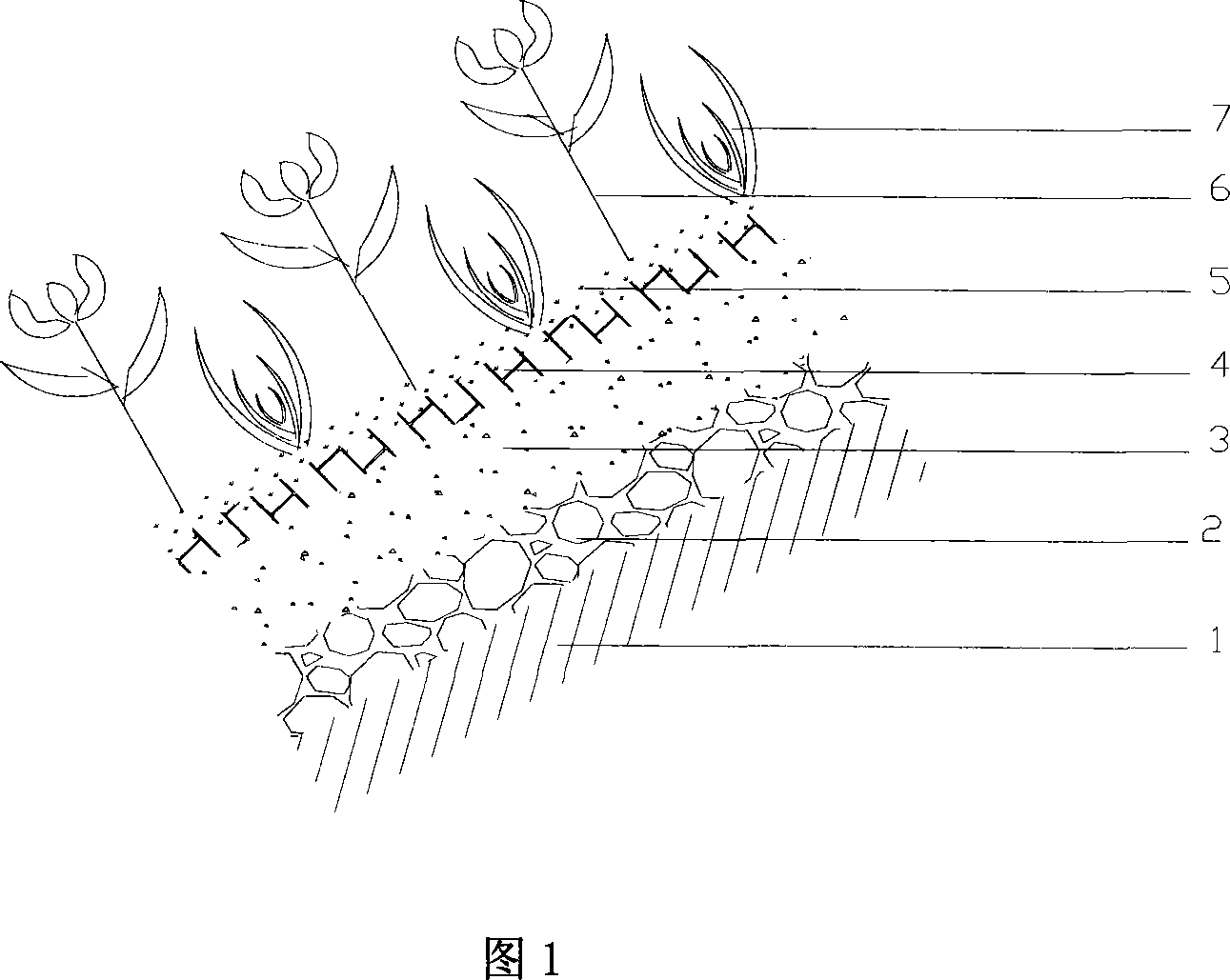

[0018] Cut the dried rice straw obtained from Jiangning, Nanjing into pieces with a length of 2-3 cm, soak it in hot water at 98°C for 6 hours, dry the pretreated rice straw, keep the moisture content at 15%, and add 5% of environmental protection Hydrophobic agent (specification brand: LS-1001, manufacturer: Shanghai Ziheng Material Technology Co., Ltd.), sizing MDI, the glue amount is 8%, the hot pressing process is: temperature 150 ° C, hot pressing time 6 minutes and hot pressing Compression pressure 3MPa, compression density 0.6kg / cm 3 . The formed slope protection brick has a thickness of 3.5cm and two circular holes in the middle. The construction process is carried out according to the traditional ecological slope protection construction technology. The original slope protection base 1 is leveled, the hardened layer 2 is laid, and the soil layer 3 is laid. The hardened material stone is 10cm thick, and the soil layer is 30cm thick. Willows and calamus are planted in ...

Embodiment 2

[0020] Cut the dried rice straw obtained from Jiangning, Nanjing into pieces with a length of 5 cm, and soak it in hot water at 98°C for 2 hours. After the pretreated rice straw is dried, the moisture content is 5%, and 3% of an environmentally friendly hydrophobic agent is added. (Commercial tung oil, place of origin: Zigui County, Hubei Province), sizing MDI, the glue content is 15%, the hot pressing process is: temperature 180 ° C, hot pressing time 20 minutes and hot pressing pressure 5 MPa, pressing density 0.9kg / cm 3 . The formed slope protection brick has a thickness of 3.5cm and four circular holes in the middle. The construction process is carried out according to the traditional ecological slope protection construction technology. The slope protection is leveled, and the hardened materials and soil layers are laid. The hardened material waste concrete is 30cm thick, and the soil layer is 50cm thick. On the straw base, ecological slope protection bricks are laid, and ...

Embodiment 3

[0022] Cut the dried rice straw obtained from Jiangning, Nanjing into pieces with a length of 0.5 cm, soak it in hot water at 98°C for 2 hours, and dry the pretreated rice straw with a moisture content of 10%, add 1% of environmentally friendly (commercial tung oil, place of origin: Zigui County, Hubei Province), sizing MDI, glue amount is 1%, hot pressing process is: temperature 120 ℃, hot pressing time 5 minutes and hot pressing pressure 2MPa, pressing density is 0.4kg / cm 3 . The formed slope protection brick has a thickness of 3.5 cm and a circular hole in the middle. The construction process is carried out according to the traditional ecological slope protection construction technology. The slope protection is leveled and hardened materials are laid, and the soil layer is laid. The hardened material broken bricks are 20cm thick, and the soil layer is 40cm thick. Willows and calamus are planted in the holes of the slope protection bricks, and ryegrass is sown on the other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com