Method and reactor for removing organic matter, sulfide, and nitrate in wastewater synchronistically

A technology for nitrate and organic matter, applied in chemical instruments and methods, water pollutants, anaerobic digestion treatment, etc., can solve the problems of secondary pollution and high cost, and achieve the effect of no secondary pollution and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

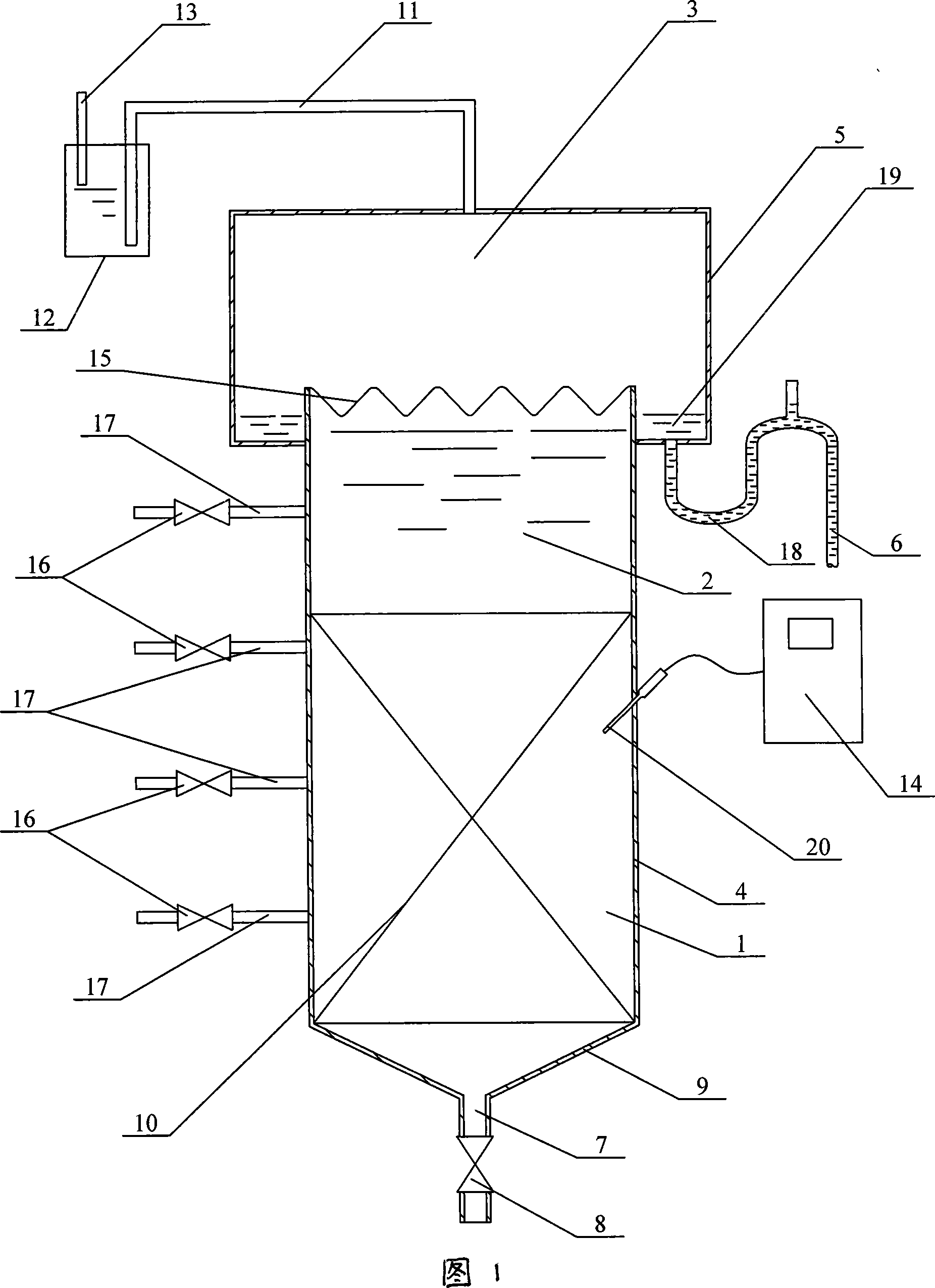

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment one: in this embodiment, the method steps of synchronously removing organic matter, sulfide and nitrate in wastewater are as follows: 1. Start the reaction device: first add activated sludge to carry out biofilm formation, and then only add inorganic The substrate is used to domesticate sulfur autotrophic denitrifying bacteria, and the inorganic substrate consists of reducing sulfur-containing compounds (electron donor), nitrate (electron acceptor), sodium bicarbonate (inorganic carbon source) and dipotassium hydrogen phosphate (phosphorus source ) composition, after the nitrate removal rate reaches 80%, after the sulfur autotrophic denitrifying bacteria occupy a dominant position in the system, then add C to the original substrate 2 ~C 6 carbon-containing organic compounds and increase the dosage of nitrate in the influent to promote the growth of heterotrophic denitrifiers. Finally, the balance between sulfur autotrophic denitrifiers and heterotrop...

specific Embodiment approach 2

[0027] Specific implementation mode two: In this embodiment mode, the reducing sulfur-containing compound is Na in step one 2 S, H 2 S or Na 2 S 2 o 3 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: In this embodiment, the nitrate is KNO in step one 3 or NaNO 3 . Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com