Optical filter for dental light curing machine

A technology of light curing machine and optical filter, applied in the fields of optical filter, dentistry, medical science, etc., can solve the problems of reduced filter life, cut-off wavelength drift, foaming, etc., to increase the curing depth and improve the service life , the effect of stable spectral characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The design process of the present invention will be described in further detail below in conjunction with the accompanying drawings.

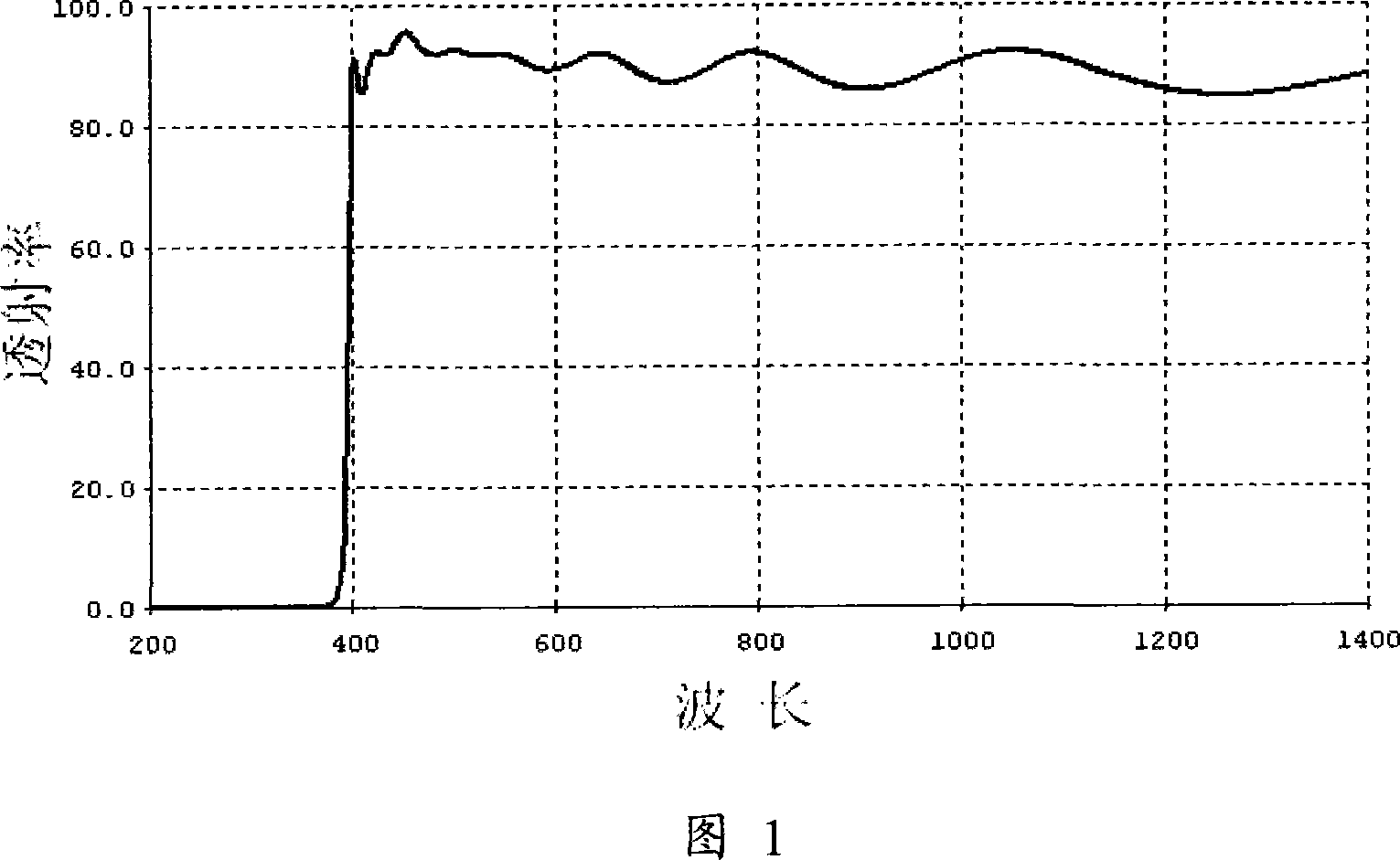

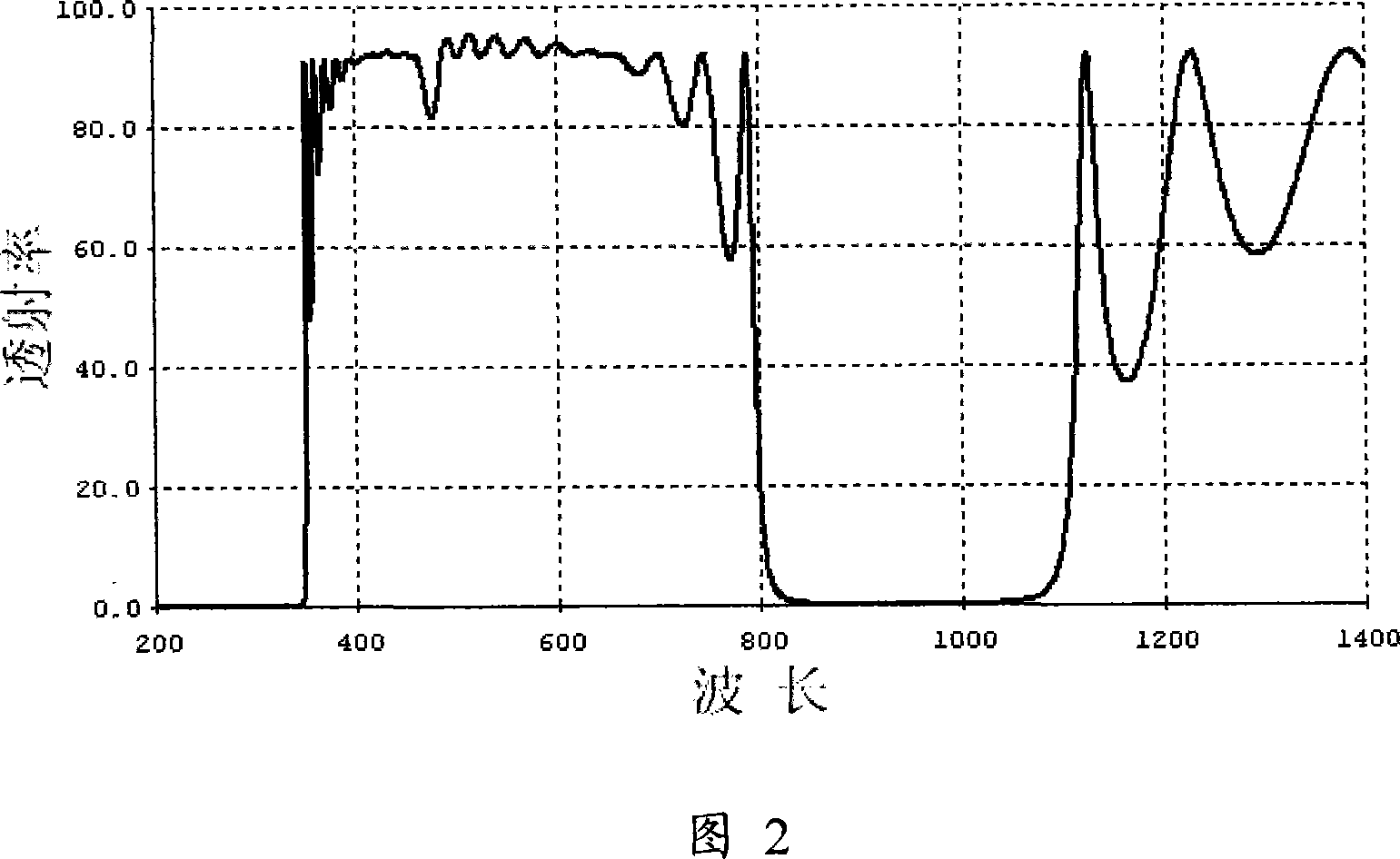

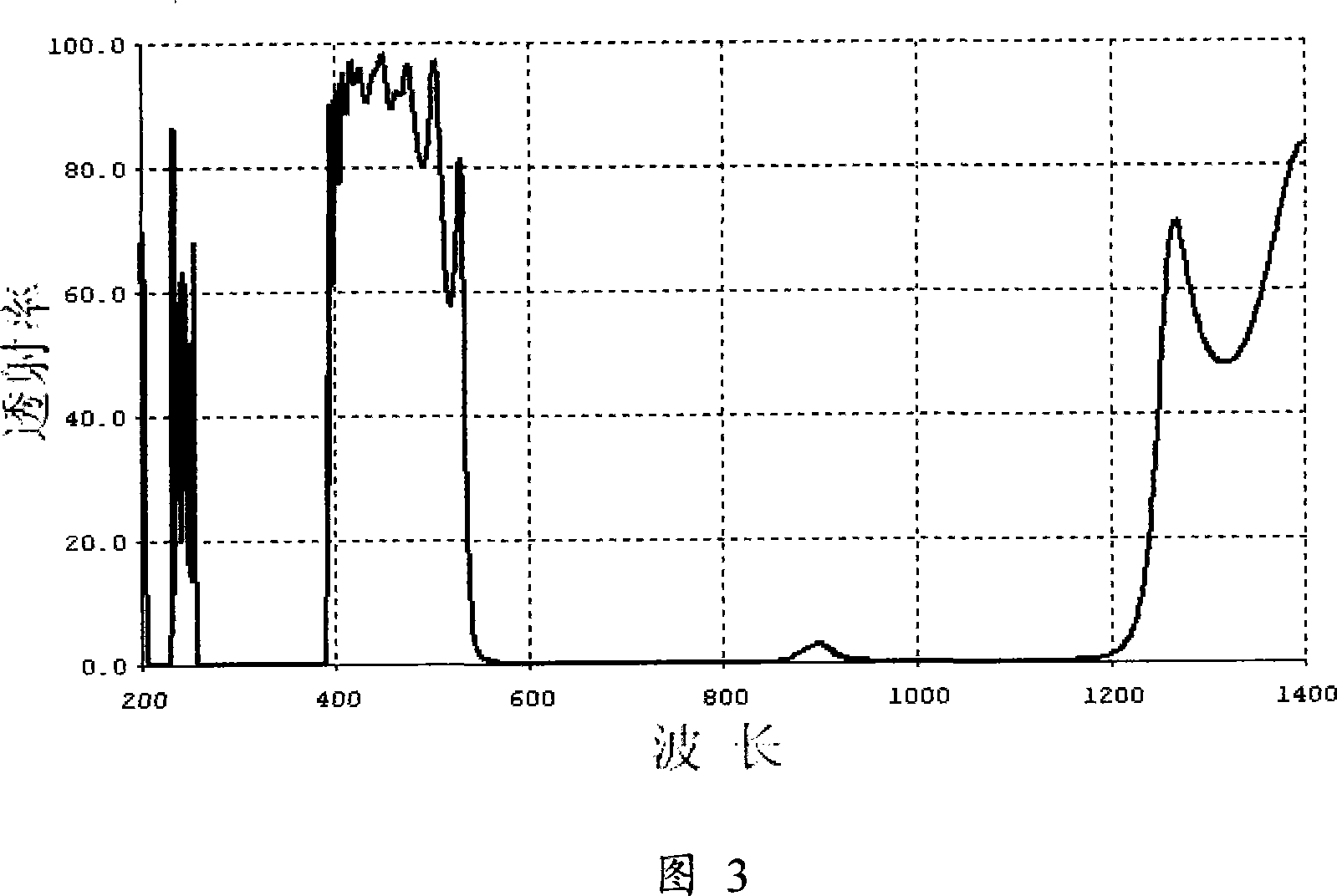

[0020] The invention discloses a dental light curing machine optical filter for eliminating ultraviolet rays and near infrared rays of the dental light curing machine.

[0021] The optical filter among the present invention is to be plated on the substrate of the ultraviolet absorbing material the high and low refractive index alternating composite dielectric film, and the high refractive index material is Ta 2 o 5 、TiO 2 Or ZnS, the low refractive index medium layer is SiO 2 、Al 2 o 3 or MgF 2 . The main structure of the film system is four cut-off filter films with different cut-off wavelengths, and the film system structure is

[0022] ( H 2 L H 2 ) 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com