Quality detection method of desepidine

A quality inspection method, Disheping's technology, is applied in the direction of measuring devices, material inspection products, and testing pharmaceutical preparations. It can solve the problems of poor quality control of finished products, insufficient inspection items, and poor reproducibility of results. Easy to operate, good reproducibility, and the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

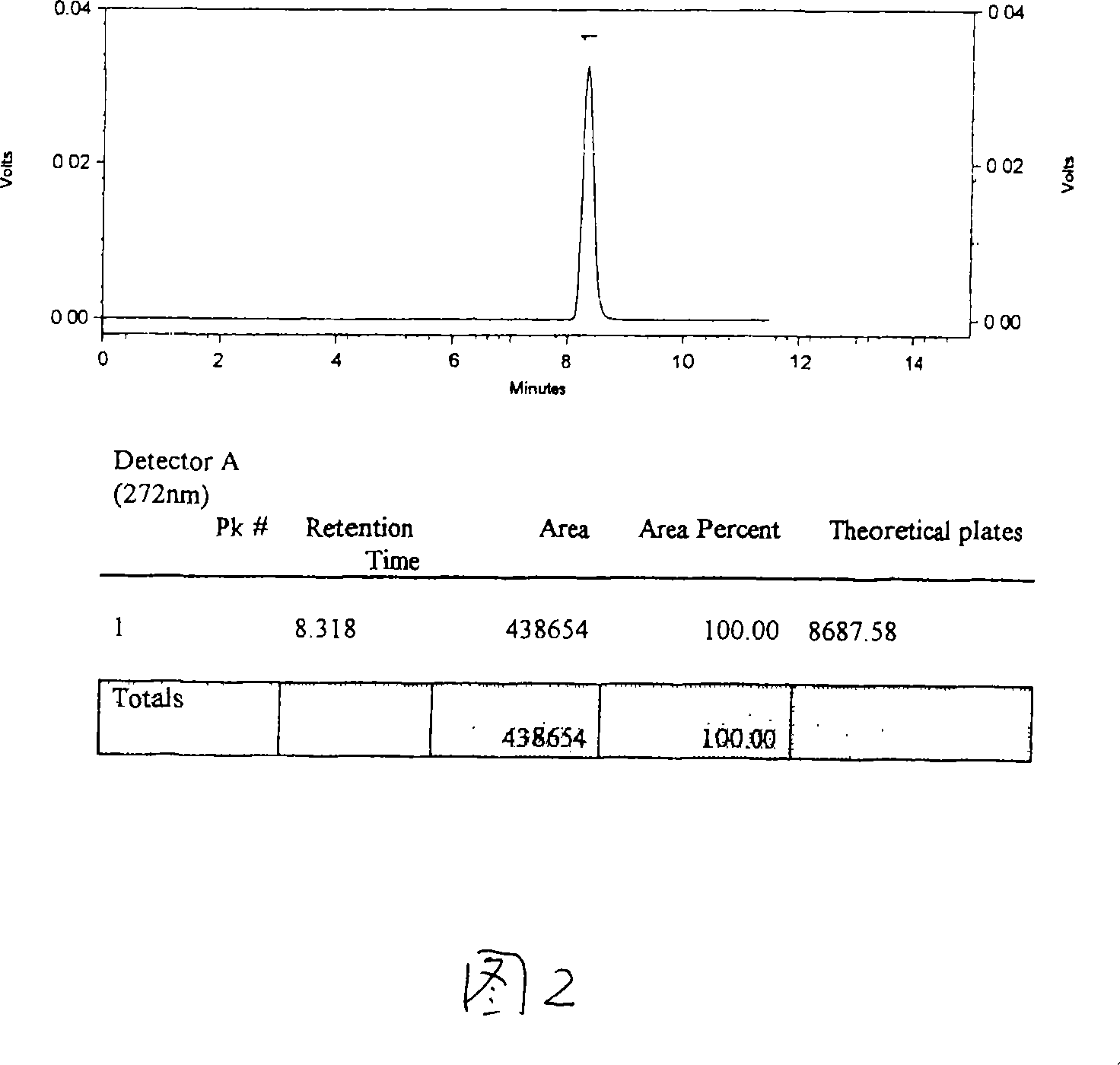

Image

Examples

Embodiment 1

[0019] Take this product containing diserpine (C 32 h 38 N 2 o 8 ) calculated on dry basis, not less than 98.5%

[0020] 【Properties】This product is white or off-white powder, odorless.

[0021] This product is soluble in chloroform, slightly soluble in methanol, ethanol, acetone, insoluble in water.

[0022] Melting point The melting point of this product (Chinese Pharmacopoeia 2005 edition two appendix VI C) is 217.0 ~ 222.0 ℃, and decomposes at the same time when melting.

[0023] Take this product for specific rotation, accurately weigh it, add methanol to dissolve and quantitatively dilute to make a solution containing about 4mg per 1ml, and measure according to the law (Chinese Pharmacopoeia 2005 edition two appendix VI E), the specific rotation is -130°~ -140°.

[0024] [Identification] (1) Take about 0.5mg of this product, add 5mg of p-dimethylaminobenzaldehyde, 0.2ml of glacial acetic acid and 0.2ml of sulfuric acid, mix well, and it will appear reddish brown. ...

Embodiment 2

[0040] 1. Appearance traits

[0041] Method: visual inspection

[0042] Check the appearance properties of the Deshepin sample, and the result sample is all off-white powder; Odorless.

[0043] 2. Specific rotation Take this product, accurately weigh it, add methanol to dissolve and quantitatively dilute to make a solution containing about 4mg per 1ml, and measure it with a polarimeter. As a result, the specific rotation ranges from -130° to 140° between.

[0044] 3. Solubility Take appropriate amount of Disheping raw material and conduct solubility test with different solvents. The results are shown in Table 1.

[0045]

water

0.1mol / L

Hydrochloric acid solution

0.1mol / L

(mg)

20.90

21.71

22.12

21.14

23.65

22.84

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com