Detecting method of rubber material and detecting device

A detection method and technology of adhesive material, which are applied to measurement devices, optical devices, semiconductor/solid-state device testing/measurement, etc., can solve the problems of low gray value of detection points, detection errors, and different gray values, etc. Achieve the effect of improving product quality, increasing accuracy, and increasing correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

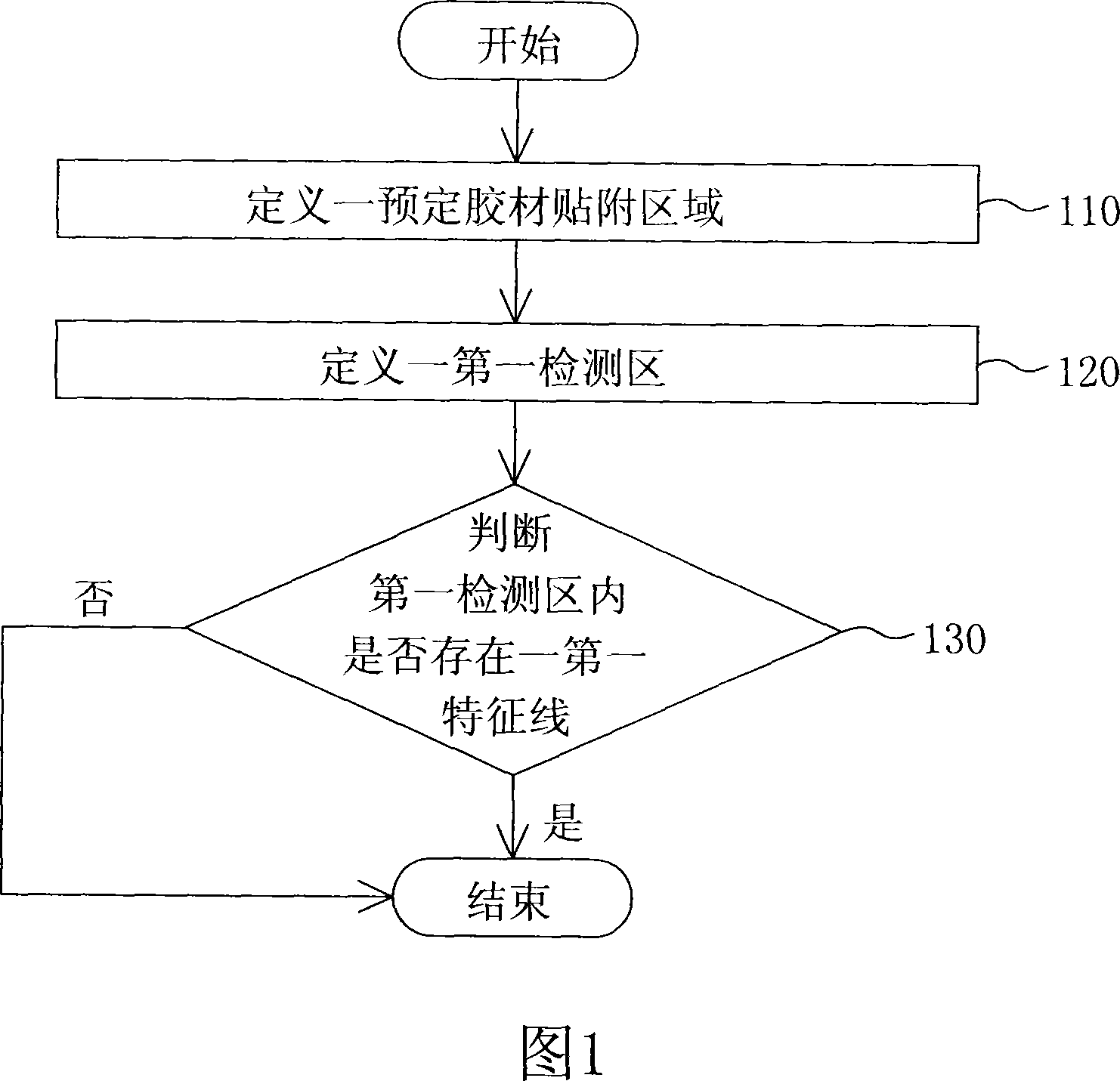

[0031] The adhesive detection method according to the first embodiment of the present invention is used to detect the adhesion status of an adhesive attached to a surface. Please refer to FIG. 1 , which is a flow chart of a detection method for adhesive materials according to a first embodiment of the present invention. A plurality of conductive circuits are arranged on the surface, where the conductive circuit is attached with glue corresponding to a first gray value, and where the conductive circuit is not attached with adhesive corresponds to a second gray value. This detection method includes the following steps.

[0032] Firstly, as shown in step 110 , a predetermined adhesive attachment area is defined on the surface, and the predetermined adhesive attachment area has a first edge.

[0033] Next, define a first detection area on the surface, as shown in step 120 . The first detection area covers a part of the first edge.

[0034] According to the detection method of t...

no. 2 example

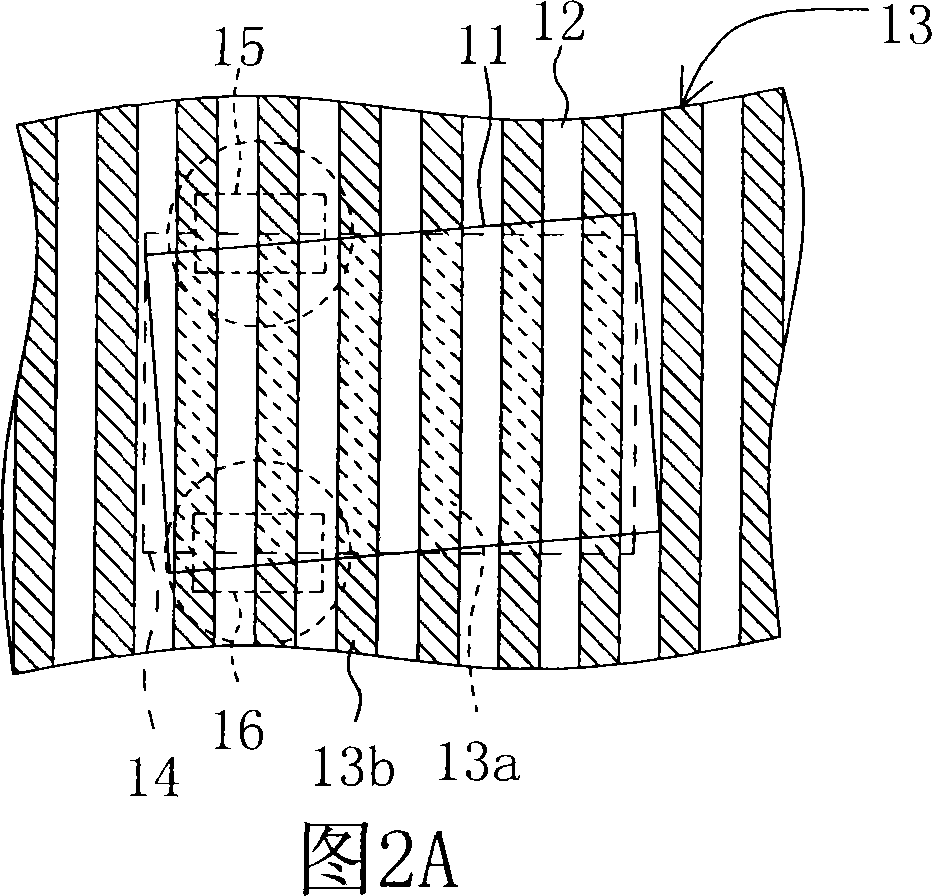

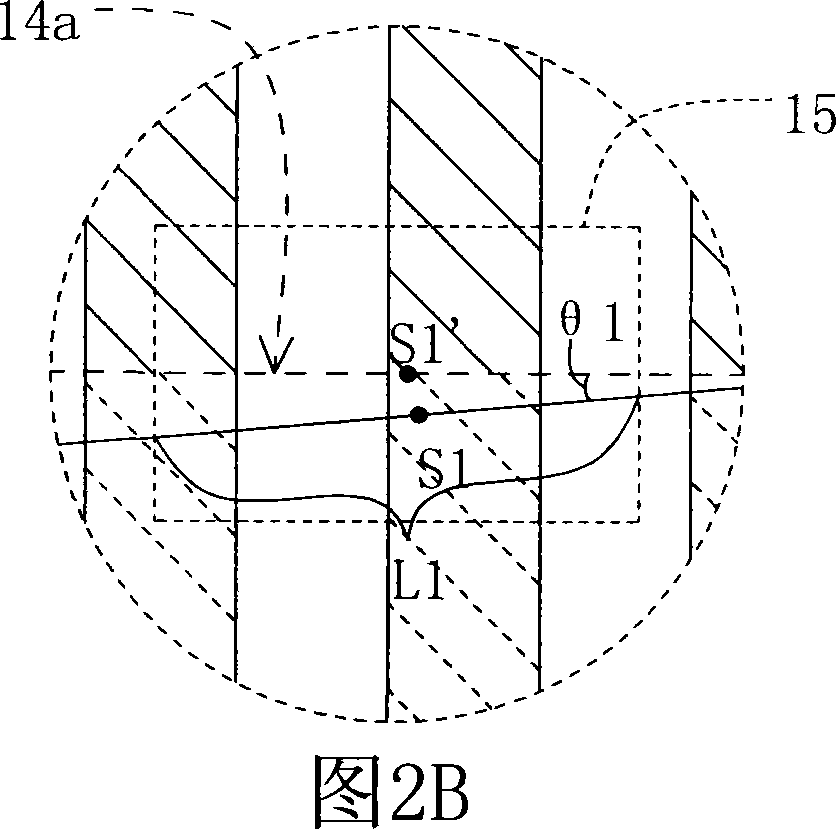

[0037] Please refer to Figures 2A to 5B at the same time. Figures 2A to 2C are schematic diagrams of adhesive materials to be detected attached to the surface in the detection method according to the second embodiment of the present invention; Schematic diagrams of the detection area, the predetermined adhesive attachment area, and the adhesive; FIG. 4 to FIG. 5B are flow charts of the adhesive detection method according to the second embodiment of the present invention. The adhesive material 11 is attached to the surface 12, and a plurality of conductive circuits 13 are disposed on the surface 12, as shown in FIGS. 2A-2C . The portion 13a of the conductive circuit 13 with the adhesive material 11 attached corresponds to a first grayscale value, and the portion 13b of the conductive circuit 13 without the adhesive material 11 corresponds to a second grayscale value. In this embodiment, the surface 12 is, for example, the surface of a printed circuit board (Printed Circuit Board,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com