Evaporator and heat absorber of separated gravity hot pipe

A gravity heat pipe and evaporator technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of large liquid mass, inability to exert the efficiency of "heat collection tubes", and uneven liquid inlet into "heat collection tubes"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

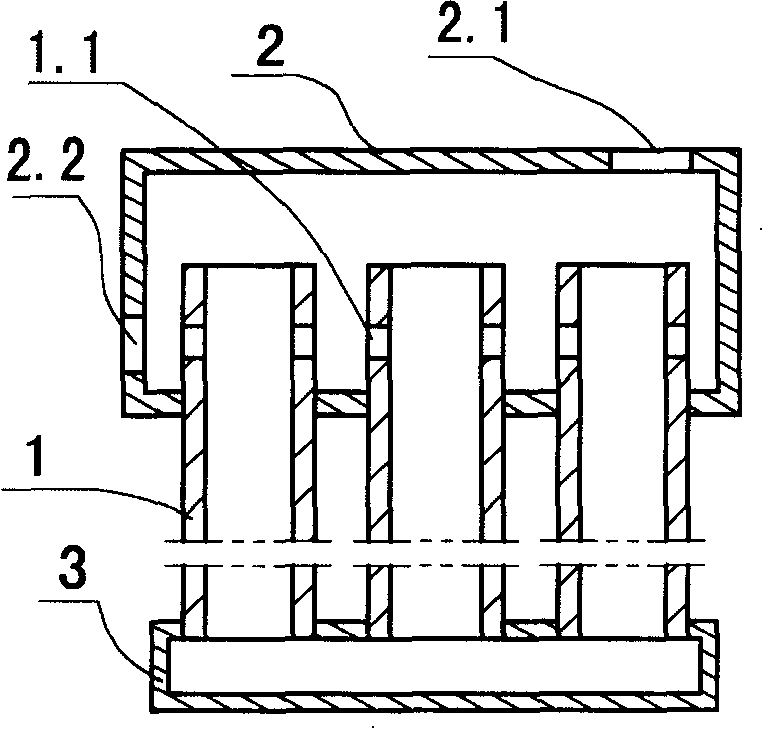

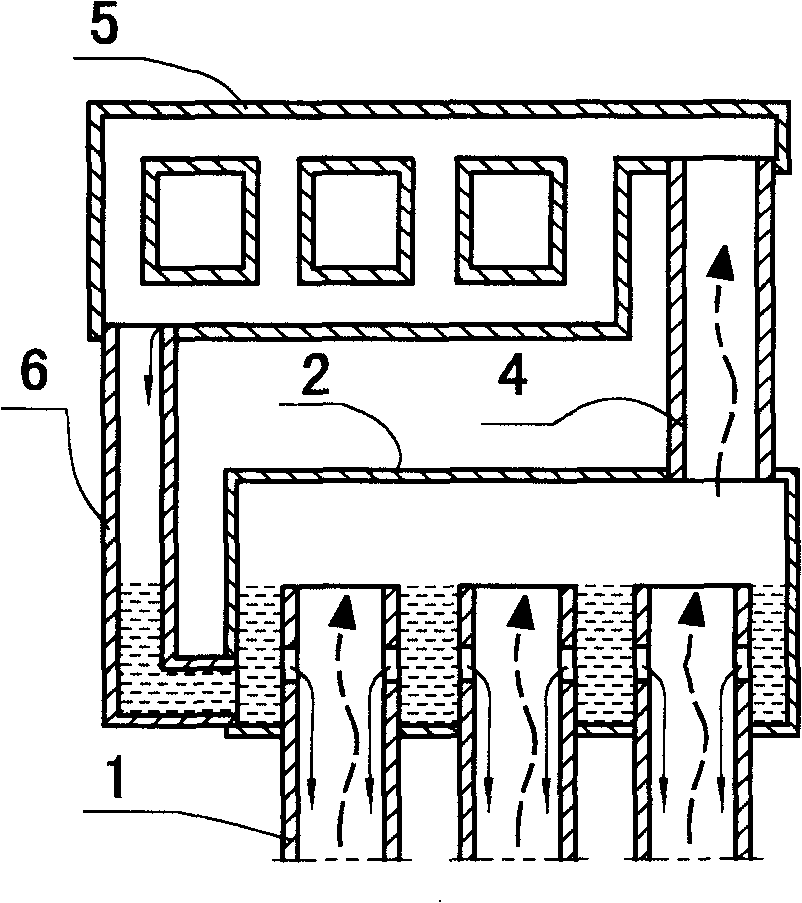

[0041] The evaporator adopting technical solution A or technical solution B is used in a separate heat pipe system. The steam outlet (2.1) of the evaporator is connected with the steam rising pipe (4) of the heat pipe system, and the liquid inlet (2.2) of the evaporator is connected to the heat pipe The liquid return pipe (6) of the system is connected, as attached image 3 . The evaporator can be used as attached figure 1 , Attached figure 2 Any form shown.

[0042] If there is no error during implementation, it can be ensured that the upper ports of all the evaporating tubes (1) are at the same height, and it can be used in applications where the heat load is fixed or where the heat load changes.

[0043] If an error occurs during implementation, it can be used in situations where the heat load varies within a certain range. Contrasting with the description in the “Summary of the Invention” of this specification, the highest evaporating tube is higher than the lowest evaporati...

Embodiment 2

[0050] Adopt technical solution C or technical solution D heat pipe type heat sink. For the occasions where the heat load is fixed, the heat pipe type heat sink of technical solution C or technical solution D can be used.

[0051] If there is no error during implementation, it can be ensured that the upper ports of all the evaporating tubes (1) are at the same height, and it can be used in applications where the heat load is fixed or where the heat load changes.

[0052] If an error occurs during implementation, it can be used in situations where the heat load changes within a certain range. The analysis using the technical solution C is the same as the technical solution A of the first embodiment.

[0053] When the full load is small and the implementation is prone to error, technical solution D should be adopted. A capillary fabric block (12) can be set at the bottom of the upper header (2), and the capillary fabric belt (8) and the capillary fabric block (12) ) Weaving and connec...

Embodiment 3

[0057] As attached Picture 10 The technical solution is: the multiple evaporators of the separated gravity heat pipe of the present invention are matched with a condenser to form a separated heat pipe system, and a separation tank (10) and several separation tubes (9) are used to condense The reflux liquid of the evaporator is evenly distributed to each evaporator. The specific pipeline is that the steam outlet (2.1) of each evaporator is connected to a steam rising pipe, the steam rising pipes (4) of all evaporators are connected to the steam main pipe (11), and the steam main pipe is connected to the steam inlet of the condenser; The liquid outlet is connected to the liquid return pipe (6), the other end of the liquid return pipe (6) is connected to the liquid distribution box (10), the upper ends of several liquid distribution tubes (9) extend into the inner cavity of the liquid distribution box (10), the liquid distribution tube (9) A segment of the pipe wall located in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com