Steam and vacuum cleaner

A technology of vacuum cleaning and steaming, which is applied in the direction of cleaning carpets, cleaning floors, cleaning machinery, etc. It can solve the problems of steam inhalation, unsightly, short-circuit accidents, etc., and achieve the effects of reducing flow speed, expanding volume, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The following are examples illustrating the present invention according to the accompanying drawings.

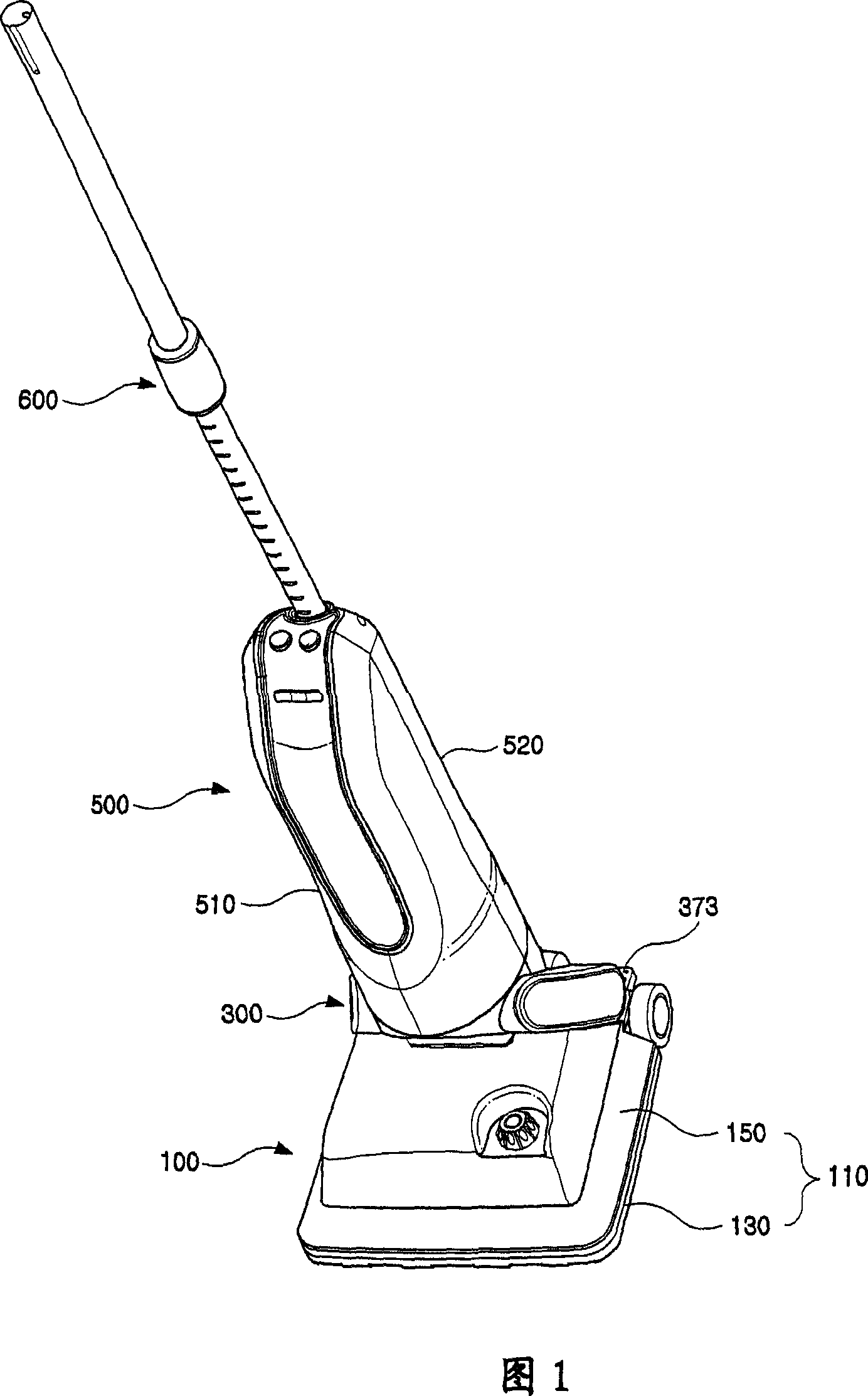

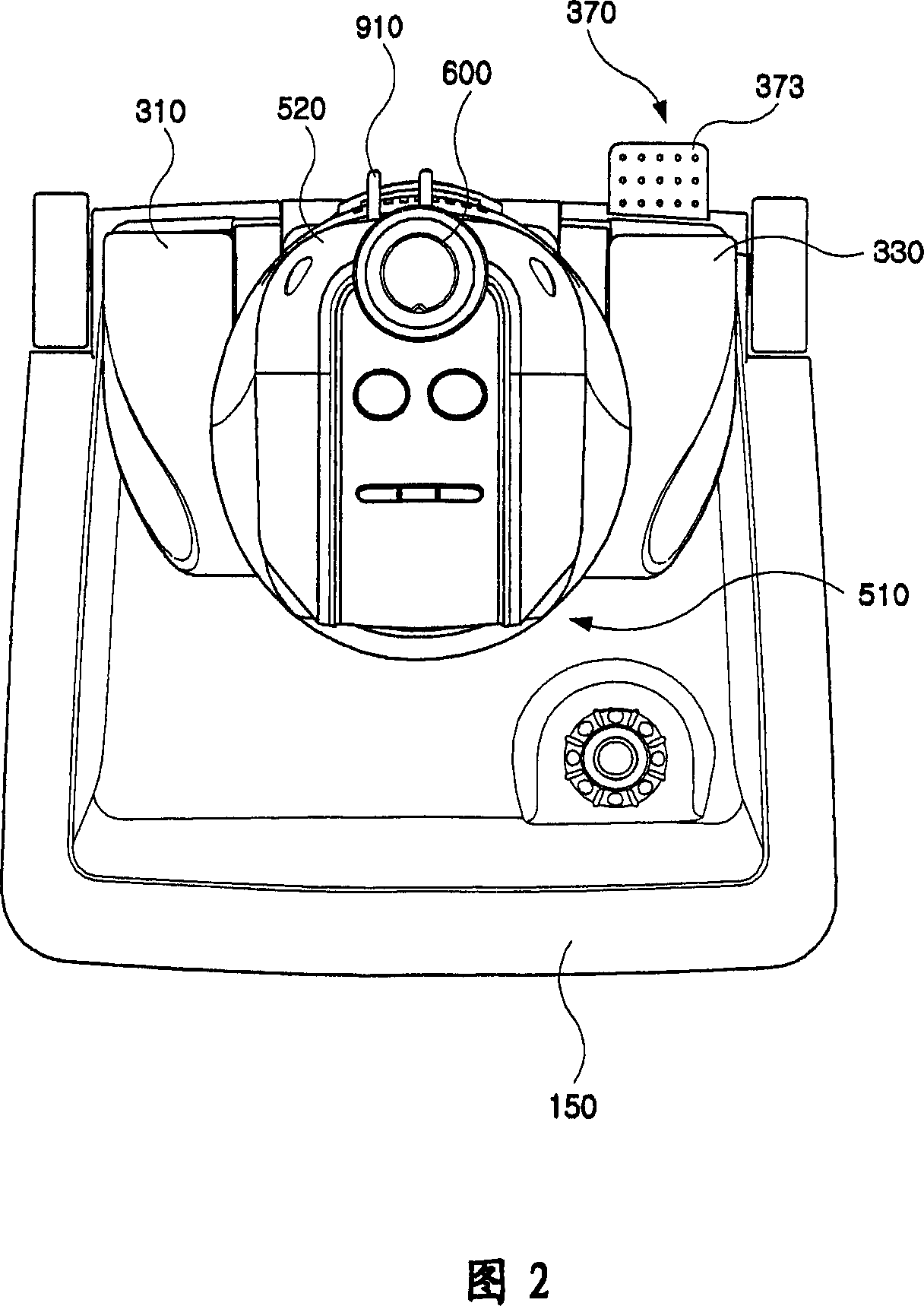

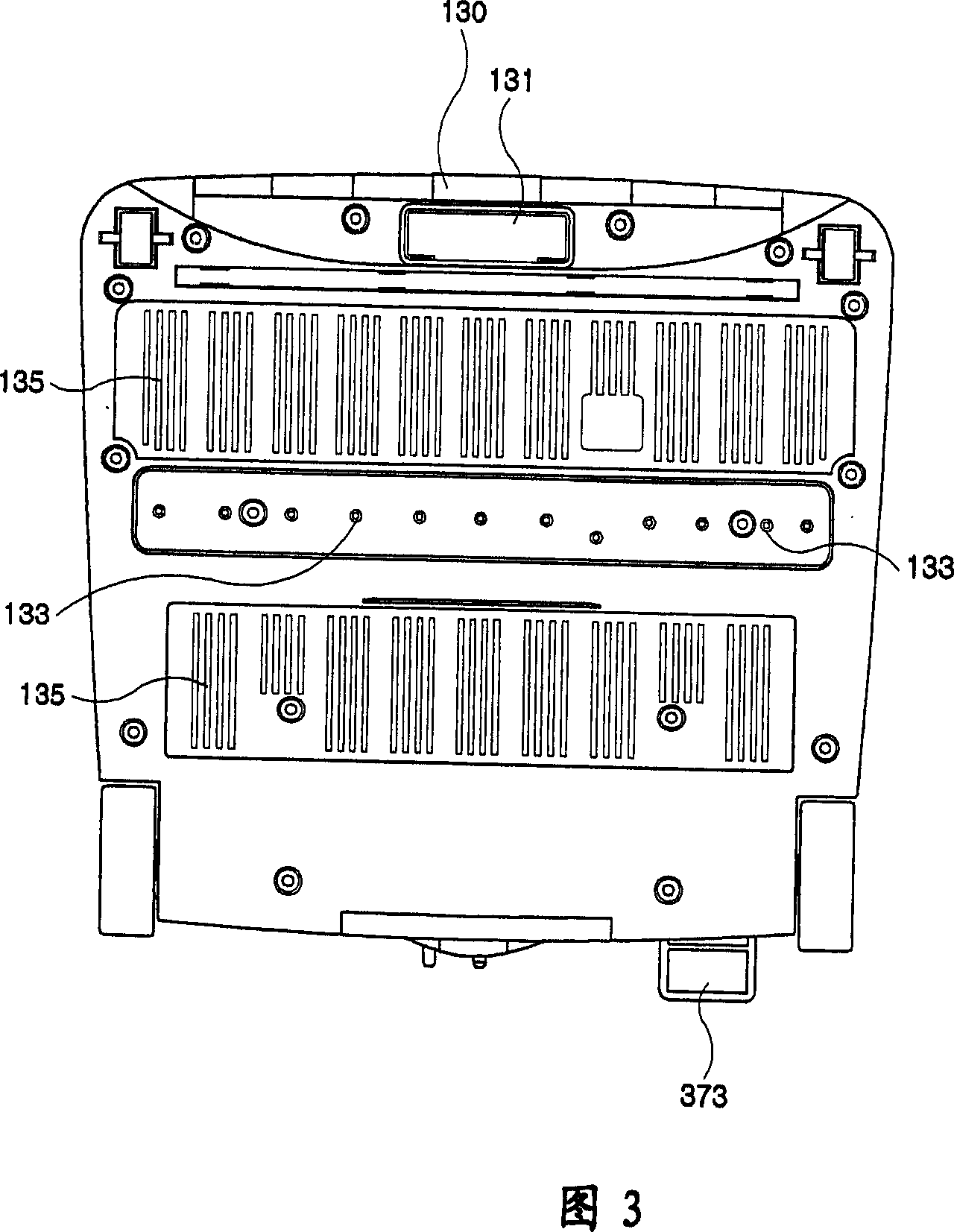

[0081] Fig. 1 is a front perspective view of a steam vacuum cleaner according to an example of the present invention, and Fig. 2 to Fig. 4 are a plan view, a bottom view and a back view of Fig. 1 .

[0082] As shown in Fig. 1 and Fig. 4, the steam vacuum cleaning machine in the present example is made up of base 100, operation main body 500, and neck 300 connecting base 100 and operation main body 500, meanwhile, operation main body There should be a handle bar 600 that can be adjusted in length on the 500, and the handle bar 600 is installed on the pipe 550 to be described in a detachable manner.

[0083] As shown in FIG. 5 , the base 100 is composed of a body 110 composed of a bottom plate 130 and an upper cover 150 , a steam generator 170 mounted on the bottom plate 130 , and a dust box 200 mounted on the back of the body 110 .

[0084] As shown in Figure 4, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com