Method for manufacturing electronic component device

A technology for electronic components and manufacturing methods, applied in the fields of electrical components, printed circuit manufacturing, semiconductor/solid-state device manufacturing, etc., can solve problems such as failure to reach the bonding state, and achieve the effects of improving efficiency, reducing costs, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

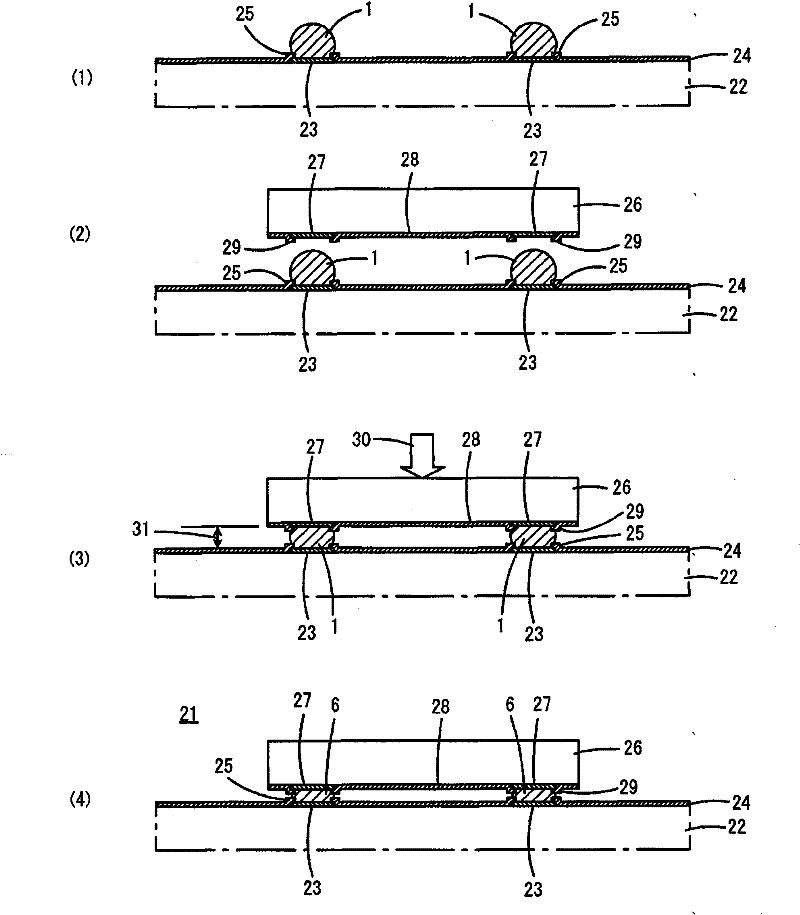

[0072] figure 1 It is explanatory drawing of 1st Embodiment of this invention. figure 1 Representative steps included in the manufacturing method of the electronic component device are shown in figure 1 (4) shows the obtained electronic device 21 .

[0073] First, if figure 1 As shown, a wiring substrate 22 as a first electronic component is prepared. The wiring substrate 22 is constituted by, for example, a resin substrate such as a glass epoxy substrate, a sintered substrate such as an alumina substrate, a Si substrate, or the like. Several substrate-side electrodes 23 are formed on the upper surface of the wiring substrate 22 , and a protective film 24 is formed on substantially the entire upper surface of the wiring substrate 22 . A part of the protective film 24 overlaps the peripheral portion of the substrate-side electrode 23 , thereby forming a bank 25 around the substrate-side electrode 23 . The banks 25 are used to prevent the diffusion of the metal nanopart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com