Resin layer surface micro structure mould-band rolling wheel shaping method and optical film

A molding method and resin layer technology, applied in optics, optical components, nonlinear optics, etc., can solve the problems of optical film microstructure defects, greatly increased manufacturing costs, unusable rollers, etc., to improve product quality and production efficiency. , to ensure the integrity and precise effect of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

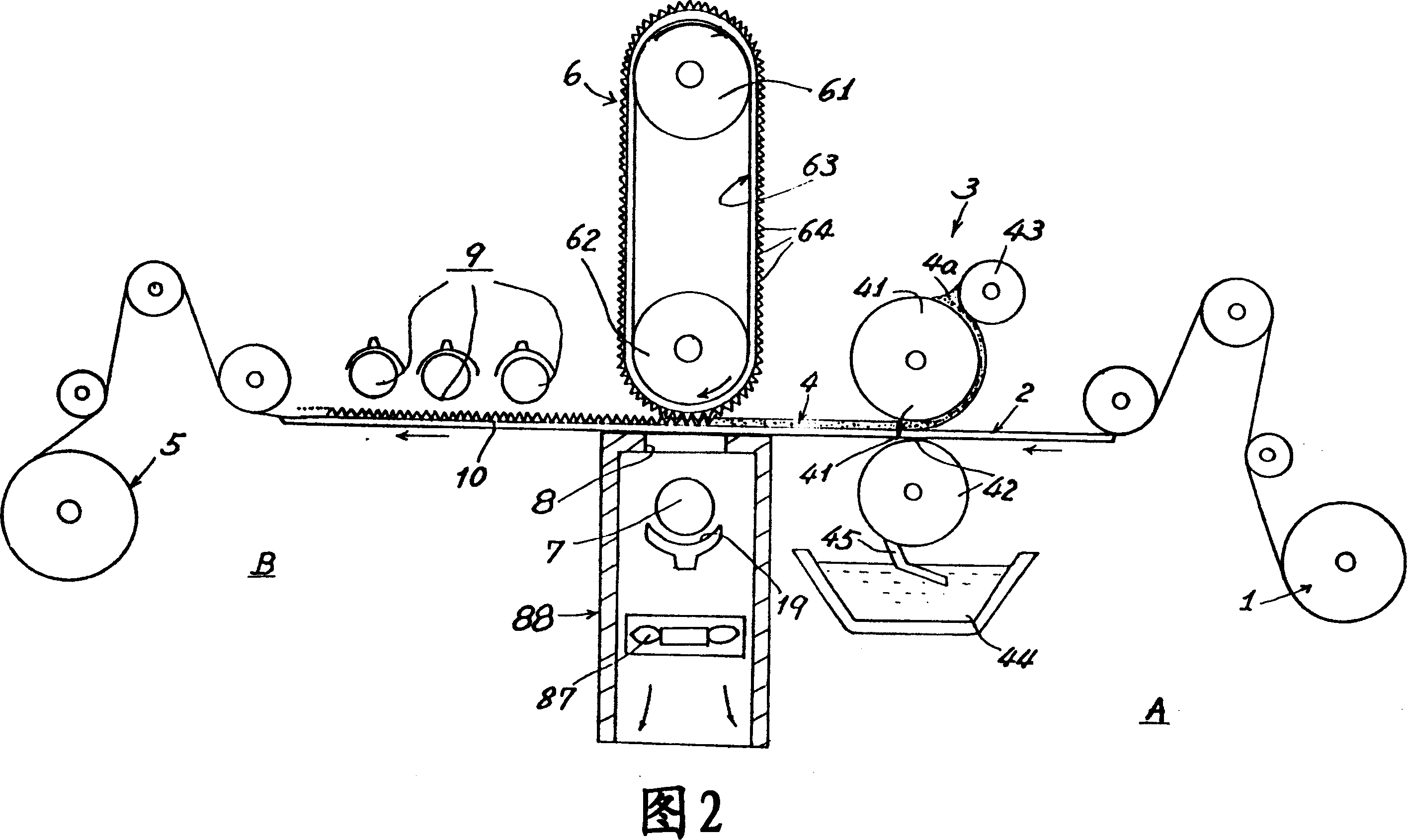

[0050] FIG. 2 shows the first embodiment of the present invention related to a method for forming the surface microstructure of a photosensitive resin layer (such as a UV adhesive layer). The molding method is to make a plastic substrate 2 feed through a gluing feed roller group 3 from its substrate roll 1 (i.e., the A end of FIG. 2 ), and make a gluing wheel of the gluing roller group 3 41 Coating a photosensitive resin layer (such as a UV adhesive layer) 4 on at least one side of the plastic substrate 2, and embossing it on the resin layer 4 through a forming mold belt roller set 6 The required microstructure (including prism array, etc.). Wherein said molding die belt roller set is composed of an upper roller 61 and a lower roller 62 arranged in parallel, wherein the upper roller 61 is a driving roller, and the lower roller 62 is a passive roller. In addition, a forming mold belt 63 (which can be a continuous endless belt (endless)) is wound around the upper and lower roll...

Embodiment 2

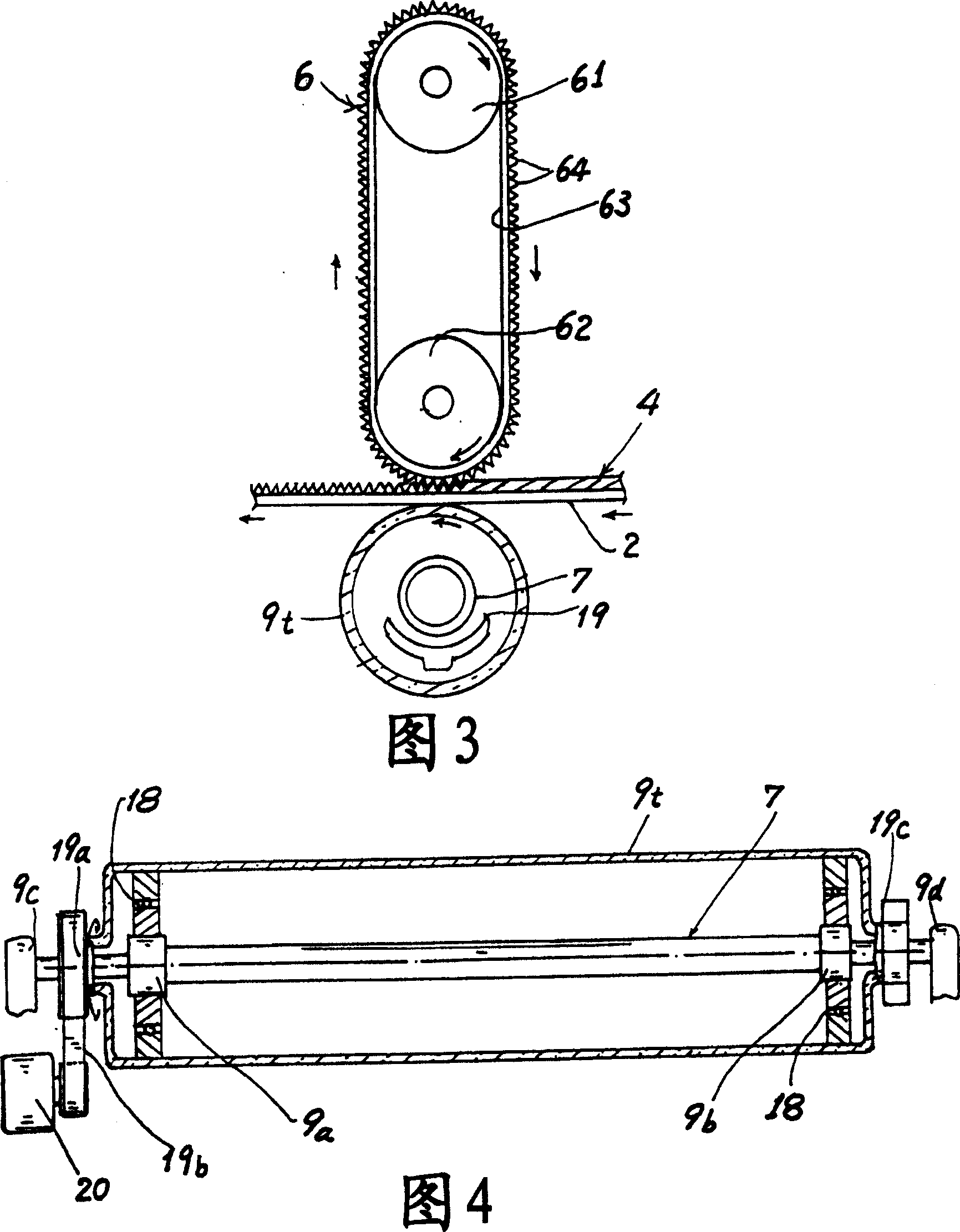

[0057] As shown in Fig. 3 and Fig. 4, the back pressure element of the forming die belt roller group 6 used in the present invention can be modified from the structure 88 shown in Fig. 2 to a back pressure element 9t that is a hollow cylinder (can be It is selected from transparent materials that can penetrate ultraviolet rays, such as quartz), and its axial direction is parallel to the other side of the forming roller group 6; and the two sides of the surface preliminary curing UV lamp 7 are installed on a pair of fixed lamps Between the seats 9a, 9b, two fixed lamp holders 9a, 9b (as shown in Figure 4) are fixedly mounted on a pair of fixed bases 9c, 9d, and are respectively pivotally connected to the peripheral edges of the two fixed lamp holders 9a, 9b. A pair of bearings 18, a hollow quartz tube 9t is stably fixed on the outer edges of the two bearings 18, and a driving end 19a of the hollow quartz tube 9t is connected to a transmission 19b, and a motor 20 is used to drive...

Embodiment 3

[0060] As shown in Figure 5, another preferred design of the forming mold belt roller set 6 used in the present invention includes: a pair of upper rollers 61a, 61b are linked and driven by a synchronous motor, and the lower roller 62 , A forming mold belt 63 is wound on the upper rollers 61a, 61b and the lower rollers 62. The roller 61a is used to take up the mold belt 63 unwound from the roller 61b. On the mold belt surface of this forming mold belt 63, desired microstructure, ornamental pattern or pattern 64 have been made; A back pressure plate 88 is axially parallel and pivotally mounted on the other side of the described forming roller group 6, and makes The distance between the back pressure plate 88 and the forming roller set 6 can be adjusted to adjust the pressure applied by the forming roller set 6 on the photosensitive resin (such as UV glue) layer 4 of the plastic substrate 2, When the plastic substrate 2 coated with the photosensitive resin layer (such as UV glu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com