Heating cooker

A technology for cookers and heating chambers, which is applied to electric heating fuels, steam cooking utensils, lighting and heating equipment, etc., can solve problems such as increased cost, unsuitability for household microwave ovens, and narrow irradiation range of laser monomers, and achieves prevention of delicious ingredients. The effect of reducing and preventing the reduction of delicious ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

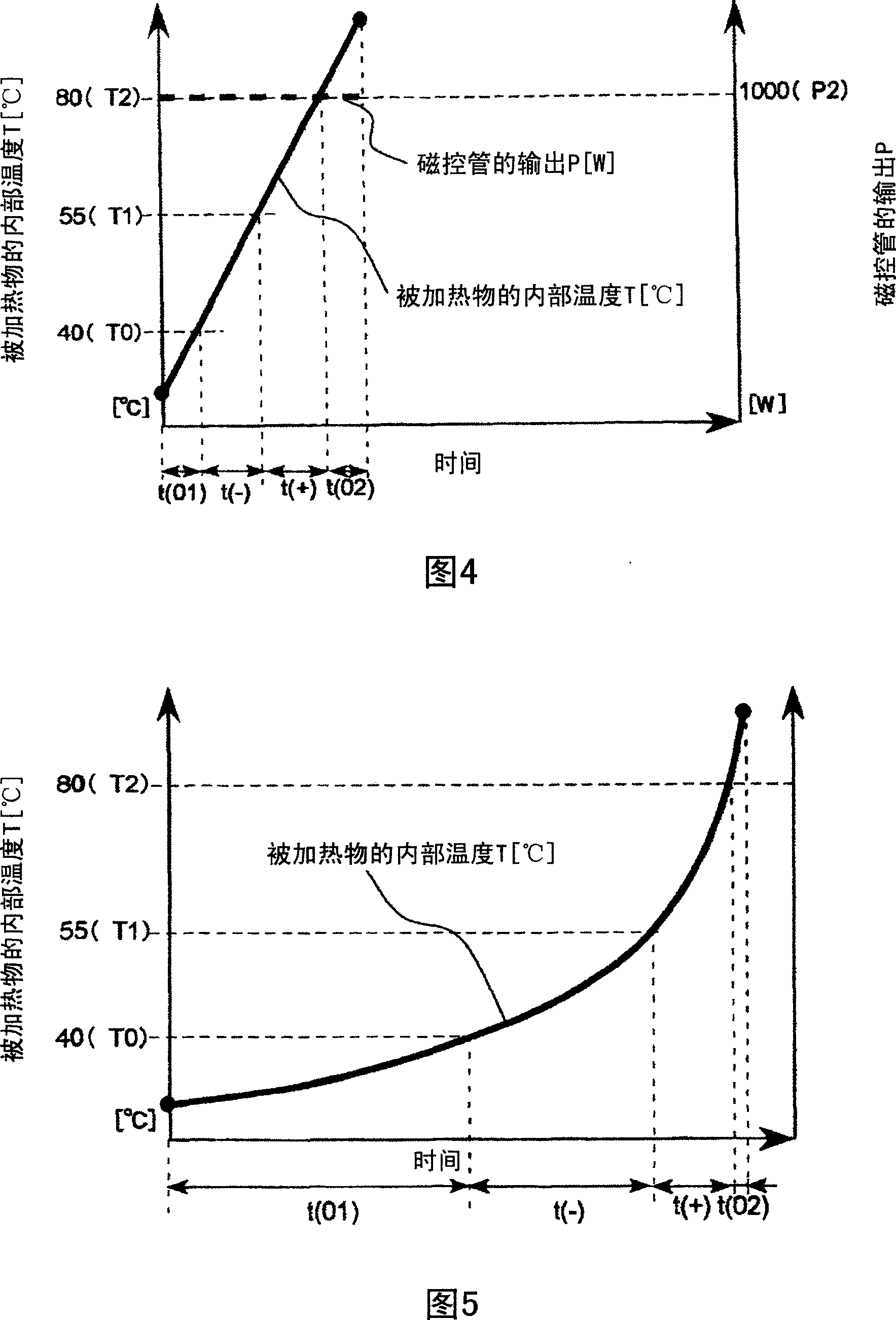

[0127] Fig. 6 shows the temporal change of the internal temperature of the object to be heated and the heating pattern during heating and cooking in the microwave oven according to the second embodiment of the present invention.

[0128] The heating and cooking mode of the microwave oven 1 of the present invention is as follows: at the beginning of heating, a combination of low-output microwave heating and low-output oven heating is performed, then high-output microwave heating is performed, and then low-output oven heating and low-output oven heating are combined. Steam heating for heating and finally grilling for heating.

[0129] Here, each heating mode is described in detail.

[0130] First, cooking is performed by combining microwave heating with low output (350W) and oven heating with low output (650W) until the internal temperature of the object reaches T0.

[0131] Since the temperature of the heating chamber is low at the beginning of heating, the ability to heat the...

Embodiment 5

[0167] Fig. 9 is a structural diagram of a microwave oven according to a fifth embodiment of the present invention seen from the front.

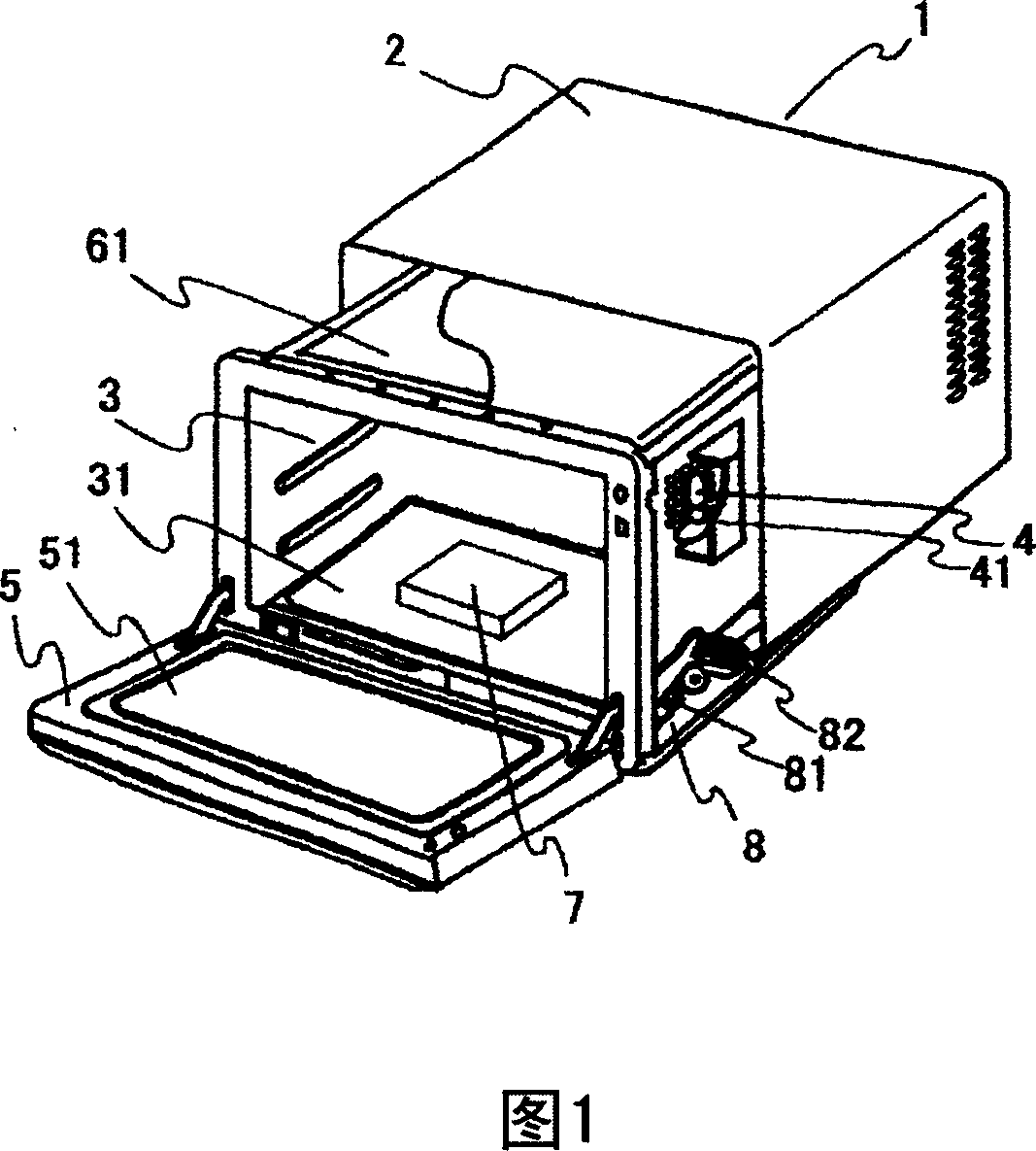

[0168] The present microwave oven 1 has a structure in which a heating chamber 3 and a machine chamber (not shown) on the heating chamber side are surrounded by a casing 2 .

[0169] The object to be heated 7 is placed on the workbench 31 arranged at the lower part of the heating chamber 3 and then heated and cooked.

[0170] The magnetron arranged in the mechanical room, the upper heater arranged above the heating chamber 3, and the hot air heater (any one of which is not shown) arranged at the rear of the heating chamber are heating mechanisms. The heating and cooking of the object to be heated 7 on the 31.

[0171] Here, a temperature sensor 91 is arranged on the side of the heating chamber 3, and a temperature estimation mechanism (not shown) is arranged in the machine room. The surface temperature of the object 7 to be heated is measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com