Polysaccharides nano material with antibiotic function, preparing method and application thereof

A technology of nanomaterials and polysaccharides, which is applied in the field of antibacterial functional polysaccharide nanomaterials and its preparation, can solve the problem of high toxicity of crosslinking agents, adverse effects on the integrity of cell macromolecular drugs, and the particle size of copper-loaded chitosan particles. major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

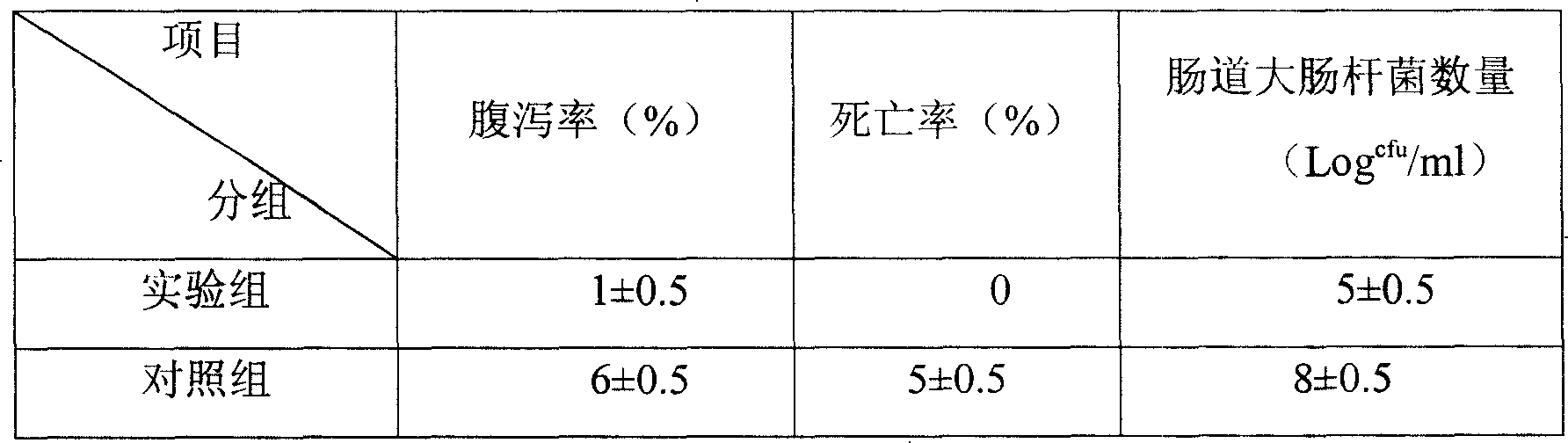

Embodiment 1

[0026] Preparation weight concentration is the aqueous solution of 1% carboxymethyl chitosan (molecular weight 100000, degree of substitution 85%, degree of deacetylation 95), under magnetic stirring condition (stirring speed 600rpm) will concentration be the CuSO of 100mmol / L 4 The solution (20ml) was added dropwise to 100ml of a 1% carboxymethyl chitosan solution (pH 4) and the temperature was kept constant at 25° C. at a rate of 300ml / h. Stirring was continued for 30 minutes after the addition was completed. The pH adopts the NaOH solution that weight concentration is 1% to adjust;

[0027] The resulting reaction mixture was centrifuged at 15,000 rpm for 4 h with a centrifuge, and the centrifuged solid was repeatedly washed with deionized water, washed with BaCl 2 Test solution to no SO 4 2- Existence, the obtained solid was dispersed in 100ml of water under the action of ultrasound. The resulting dispersion was dried by spraying (dryer inlet temperature 165° C.) to obta...

Embodiment 2

[0030] Preparation weight concentration is the aqueous solution of 1% carboxymethyl chitosan (molecular weight 100000, degree of substitution 85%, degree of deacetylation 95), under magnetic stirring condition (stirring speed 600rpm) will concentration be the CuSO of 100mmol / L 4 The solution (20ml) was slowly added dropwise to 100ml of a 1% carboxymethyl chitosan solution (pH 4), and the temperature was kept constant at room temperature at a rate of 300ml / h, and continued to stir for 30min after the addition was completed. The pH adopts the NaOH solution that weight concentration is 1% to adjust;

[0031] The resulting reaction mixture was centrifuged at 15,000 rpm for 4 h with a centrifuge, and the centrifuged solid was repeatedly washed with deionized water, washed with BaCl 2 Test solution to no SO 4 2- Existence, the obtained solid was dispersed in 100ml of water under the action of ultrasound. The resulting dispersion was freeze-dried to obtain copper-loaded chitosan-b...

Embodiment 3

[0034] Preparation weight concentration is the solution of 1% carboxymethyl chitosan (molecular weight 500000, degree of substitution 85%, degree of deacetylation 95), under magnetic stirring condition (stirring speed 600rpm) will concentration be the CuSO of 100mmol / L 4 The solution (20ml) was slowly added dropwise to 100ml of a 1% carboxymethyl chitosan solution (pH 4) and the temperature was kept constant at room temperature at a rate of 300ml / h. Stirring was continued for 30min after the addition was complete. The pH adopts the NaOH solution that weight concentration is 1% to adjust;

[0035] The resulting reaction mixture was centrifuged at 15,000 rpm for 4 h with a centrifuge, and the centrifuged solid was repeatedly washed with deionized water, washed with BaCl 2 Test solution to no SO 4 2- Existence, the obtained solid was dispersed in 100ml of water under the action of ultrasound. The resulting dispersion was dried by spraying (dryer inlet temperature 165° C.) to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com