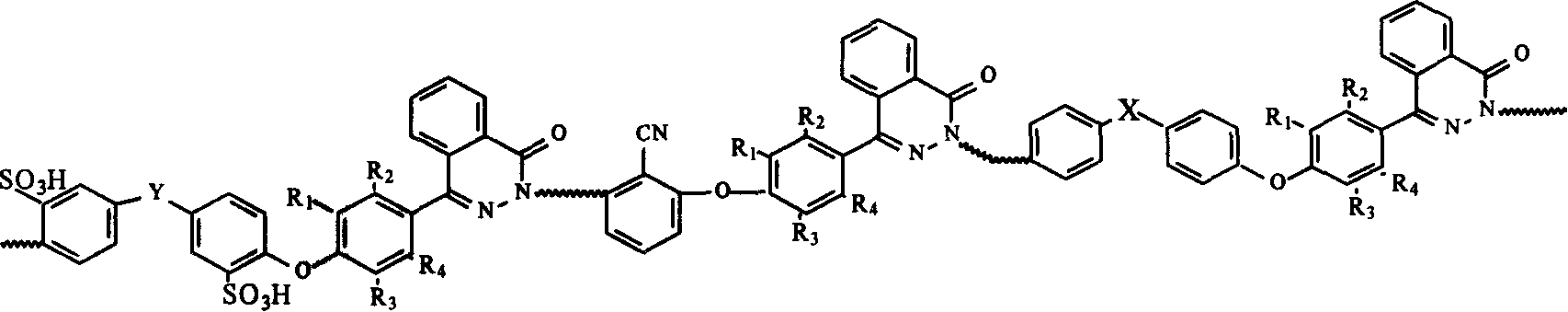

Method of preparing diazanaphthalene biphenyl type sulphonation polyarylethernitrile electrolyte film material

A phthalazine-type, electrolyte membrane material technology, applied in solid electrolyte fuel cells, secondary batteries, secondary battery components, etc., can solve the problem of high membrane swelling rate, poor high temperature oxidation resistance, and loss of mechanical strength and other problems, to achieve the effect of high proton conductivity, good chemical stability and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

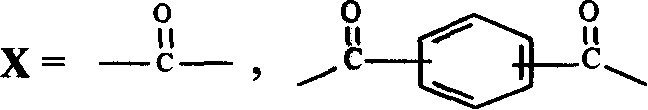

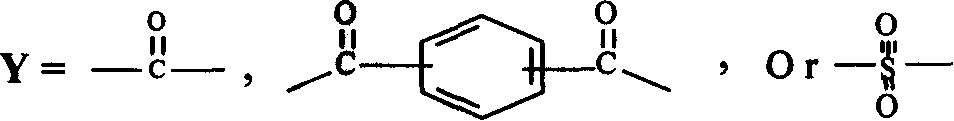

Embodiment 1

[0041] With 4.7650g (20mmol) compound 2, wherein R 1 , R 2 , R 3 , R 4 is H atom, 3.3782g (8mmol) of compound 4, wherein Y is -CO-, L is F atom, and 0.6880g (4mmol) of dichlorobenzonitrile is added to the condensing reflux device connected to the water separator and the nitrogen tube of 100mL In the three-necked flask, under electromagnetic stirring, add 4.19g of potassium carbonate, 16mL of NMP as a solvent, and 8mL of toluene as a water-carrying agent. First react at 120°C, continuously distill out toluene and water. Then the temperature was raised to 170°C for 3h. Then add 1.7456g (8mmol) of compound 3, wherein X is -CO-, L is F atom, bring water at 140°C, and then raise the temperature to 180°C for about 8-12 hours to reach the predetermined viscosity. Cool, dilute with a small amount of NMP, and pour the polymer slowly into 1:1 volume ratio methanol-water. The fibrous polymer was collected by filtration. Vacuum dry for 48 hours. Polymer intrinsic viscosity 2.0dLg ...

Embodiment 2

[0043] In a 500mL three-necked flask equipped with a stirrer, nitrogen tube, water separator and condenser tube, add 11.9125g (50mmol) of compound 2, wherein R 1 , R 2 , R 3 , R 4 H atom, 15.1306g (20mmol) compound 4, wherein Y is 4,4'-dibenzoylbenzene, L is fluorine atom, 0.2602g (10mmol) dichlorobenzonitrile, 10.36g (75mmol) potassium carbonate, 30mL NMP, 50ml toluene, heated to reflux with water for 2h. Raise the temperature to 180°C for prepolymerization for 3 hours. Add 6.9266g (20mmol) of compound 3, wherein X is 4,4'-dibenzoylbenzene, L is a fluorine atom, and 10mL of toluene is refluxed with water. After the completion of bringing water, the temperature was raised to 180°C for 20 hours of polymerization. Cool, dilute with a small amount of NMP, and pour the polymer slowly into 1:1 volume ratio methanol-water. The polymer was collected by filtration and vacuum-dried for 24 hours to obtain the target product with an intrinsic viscosity of 1.17dLg -1 (NMP, 25°C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com