Method for preparing dimethyl ether by dehydration of methanol

A technology for dehydration reaction and dimethyl ether, which is applied in the dehydration of hydroxyl-containing compounds to prepare ether, ether preparation, chemical industry and other directions, and can solve the problems of small operation flexibility, unfavorable catalyst stability, and high equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

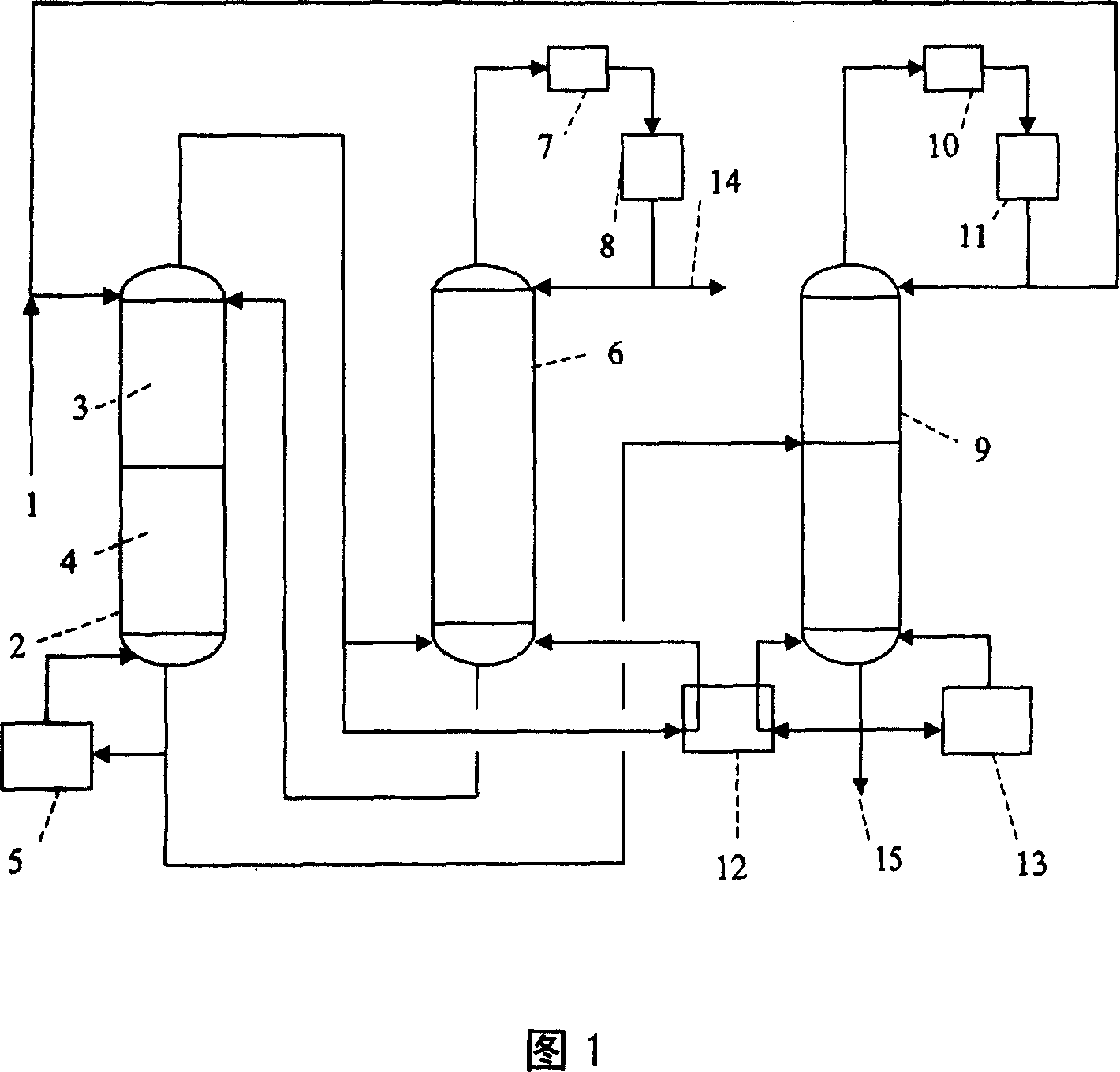

[0054] Dehydration of Methanol by Catalytic Distillation to Produce Dimethyl Ether

[0055] The catalytic distillation column includes a top condensation reflux device, a rectification section, a reaction section, a stripping section and a tower still. The inner diameter of the tower body is 50mm, and the effective height of the reaction section is 0.97m. Mix 364ml of catalyst with 1360ml of Φ5×5mm stainless steel θ mesh ring and put it into it; Φ3×3 mm stainless steel θ mesh ring, the tower kettle is heated by a resistance furnace, and industrial methanol with a purity of 99.96% by weight is used as the reaction raw material.

[0056] The catalyst is a strip-shaped particle with a diameter of 2 mm and a length of 5-10 mm. The active component is HZSM-5, the molecular ratio of silicon to aluminum is 38, and it contains 20% by weight of alumina binder. Hour.

[0057] Feed from the upper end of the reaction section 8 cm down, at a feed rate of 1.09 liters per hour, the operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com