Circulating multi-stage ultrasonic scattering method

An ultrasonic and circulating technology, applied to chemical instruments and methods, dissolving, mixing machines, etc., can solve the problems of uneven particle size, low dispersion efficiency, and large floor space, and achieve reduced energy consumption, simple maintenance, and occupied space. small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention converts the 220V, 50Hz alternating current into an ultrasonic frequency electrical oscillation signal, and the transducer converts the electrical oscillation signal output by the ultrasonic generator into an ultrasonic frequency mechanical vibration; the horn amplifies the longitudinal vibration of the transducer and transmits it to the A tool in a liquid to disperse solid particles or biological tissues in a liquid.

[0031] The dispersion of ultrasonic waves in the liquid depends entirely on the cavitation of the liquid. However, if the acoustic wave intensity is lower than the cavitation threshold, or the cavitation is deliberately controlled, cavitation will not occur. In the final analysis, ultrasonic dispersion relies on the basic mechanism of "cavitation".

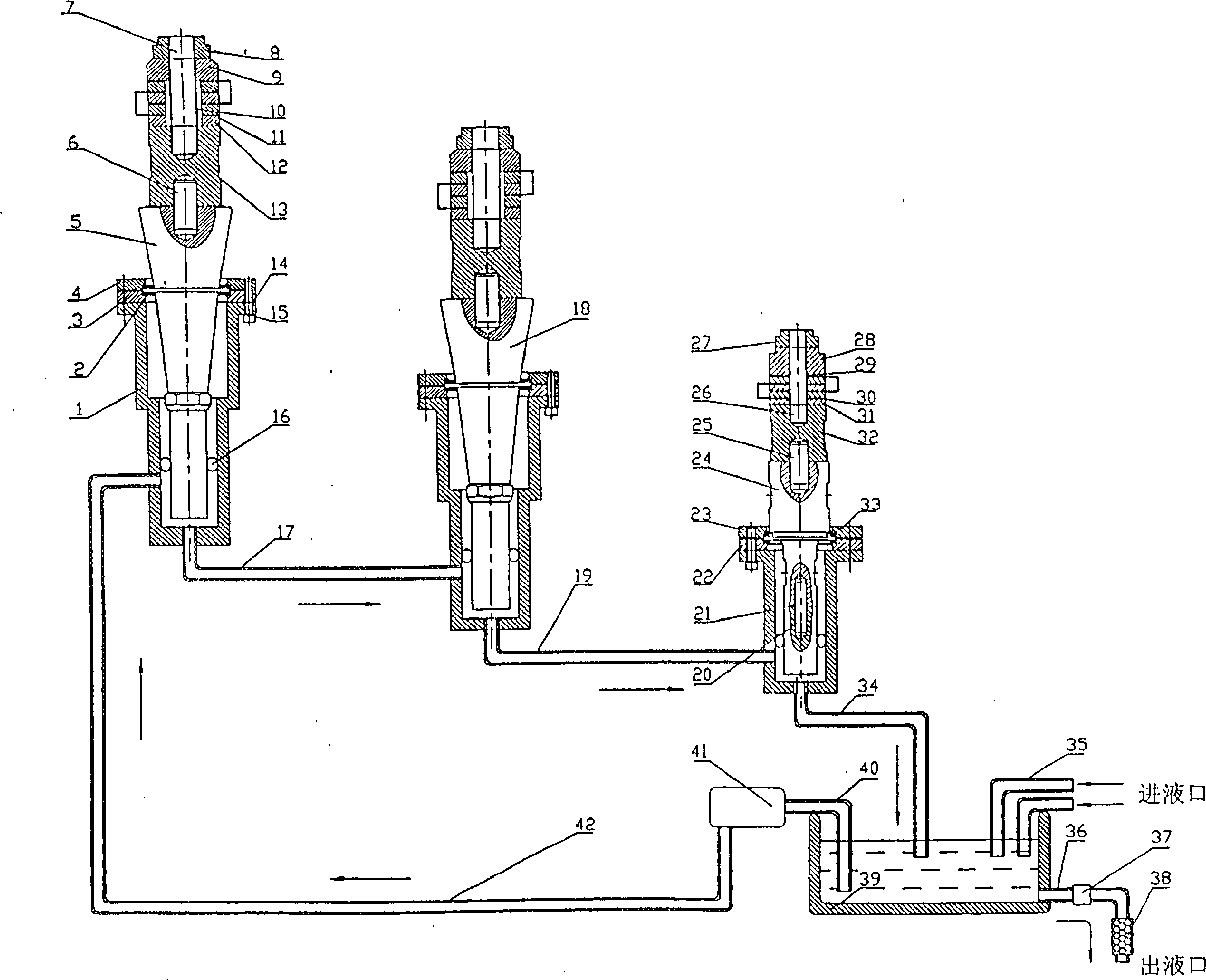

[0032] The present invention proposes a circulating multi-stage ultrasonic dispersing machine, in which multiple sets of ultrasonic dispersing devices of different power and frequency are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com