Fogger, reactor using same and method for preparation of oxime

A sprayer and reactor technology, applied in chemical instruments and methods, chemical/physical/physical-chemical nozzle reactors, oxime preparation, etc., can solve problems such as not following the target, and achieve the effect of inhibiting direct contact and inhibiting decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

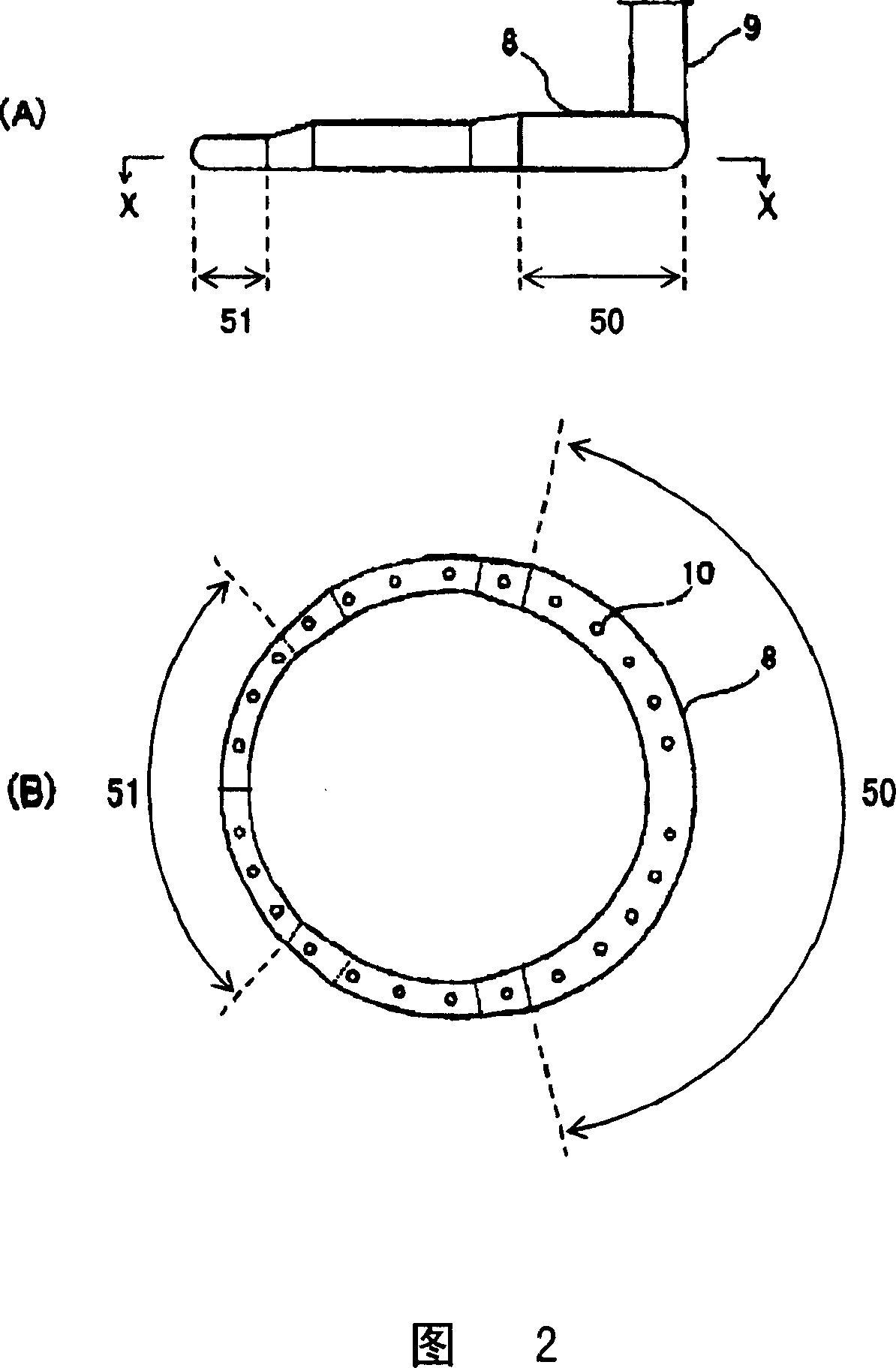

Method used

Image

Examples

Embodiment 1

[0058] Put the catalyst in the transparent vinyl chloride pipe, let water flow in, and find the minimum flow rate required for the catalyst to discharge.

[0059] As a catalyst, use a maximum particle size of 150 μm or less, an average particle size of 38 μm, and a density of 2.2 g / cm 3 titanium silicate catalyst.

[0060] Place the catalyst at a position 400mm away from the other end of the pipe (length 600mm) closed at one end, and supply water from the other end through a flow meter so that the water flows from the position 500mm away from the other end (about 100mm away from the catalyst). The hole of 2mmΦ in the lower part flows out.

[0061] Change the pipe diameter and flow rate of water. The results are shown in Table 1.

[0062] By setting the flow velocity to 0.12 m / sec or more, the catalyst can be easily discharged.

[0063] Table 1

[0064] No.1

No.2

25A piping (inner diameter: 27.6mmφ)

Catalyst amount: 4.4g

15A piping (inner diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com