Electrostatic chuck

一种静电卡盘、电极的技术,应用在电路、电气元件、应用静电吸引力的保持装置等方向,能够解决电介质层绝缘破坏等问题,达到提高均热性、缩短饱和温度的时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

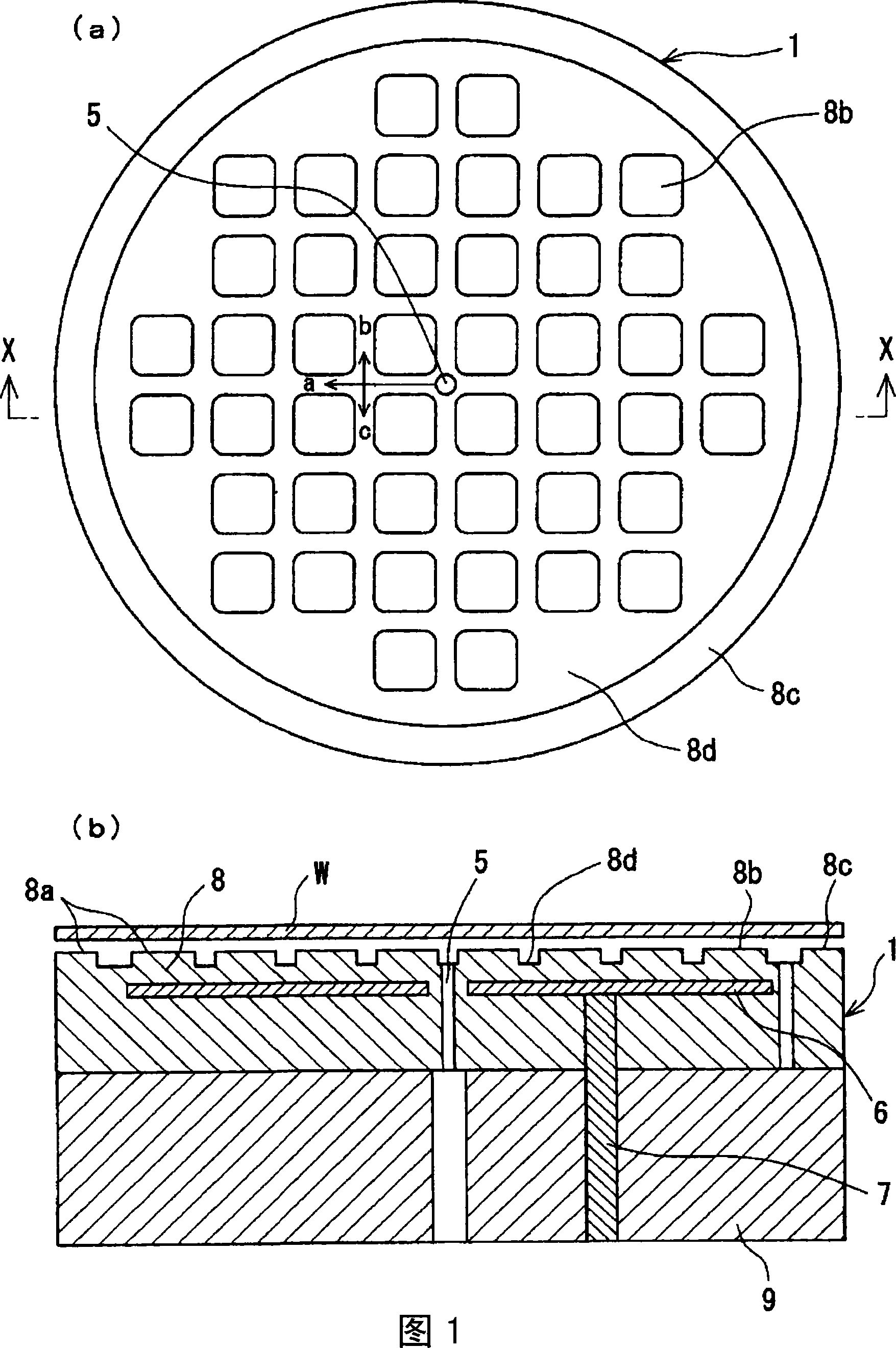

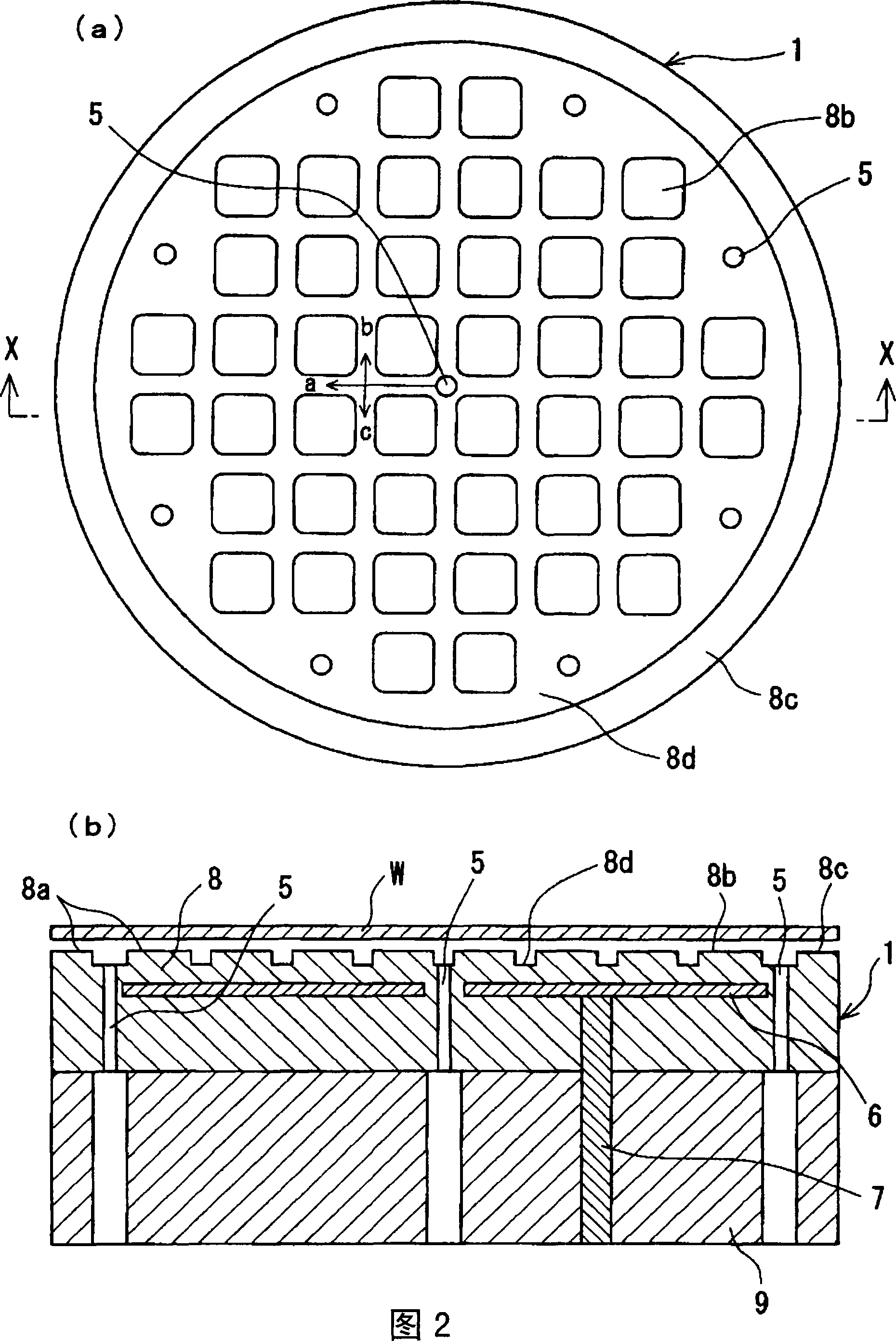

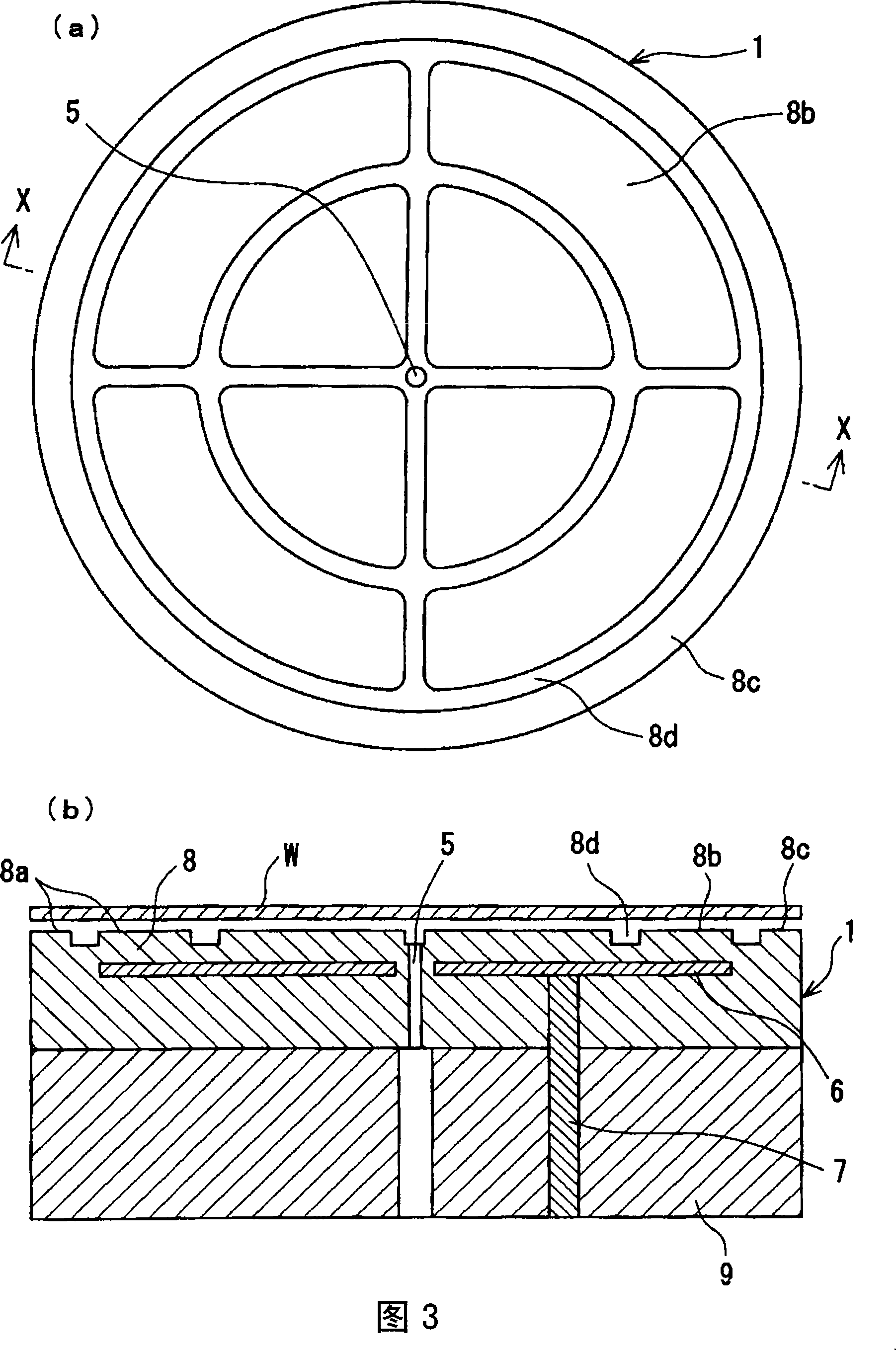

[0097] Specific examples of the present invention will be described below using an electrostatic chuck as an example.

[0098] First of all, the aluminum oxide Al 2 o 3 The formed plate-shaped body will be described as an example. Al with a purity of 99.9% by mass at an average particle size of 1.0 μm 2 o 3 0.2% by mass of CaO and SiO2 are added to the powder as a sintering aid, and a binder and a solvent are added to make a slurry, which is then formed into multiple green sheets of alumina by the doctor blade method.

[0099]On one of the alumina green sheets, a metal paste of molybdenum, which is an electrode for adsorption, was printed in a predetermined electrode pattern by a screen printing method. Further, the remaining alumina green sheets were laminated on the surface opposite to the surface on which the metal paste was applied. On the other hand, a plurality of alumina green sheets on which the metal paste was not printed were stacked, and power feeding holes wit...

Embodiment 2

[0117] An electrostatic chuck was produced in the same manner as in Example 1. The groove is machined by a Machining Center, so that the dimensions of the R shape connecting the groove and the curved surface of the convex part are 0.005, 0.01, 0.05, and 0.1mm, respectively, and the dimensions of the R shape connecting each side of the convex part are 0.5mm. Accordingly, an electrostatic chuck was fabricated in the same manner as No. 3 of Example 1. However, in making the dimension of the R-shape connecting the groove and the curved surface of the convex part 0.1 mm, the depth of the groove was made 0.1 mm. This was evaluated in the same manner as in Example 1. The results are shown in Table 2.

[0118] (Table 2)

[0119] Sample No.

Dimensions of R shape (mm)

Wafer temperature distribution (°C)

up to the saturation temperature

time (seconds)

7

0.005

0.8

2.4

8

0.01

0.7

2.2

9

0.05

0.6

2.2...

Embodiment 3

[0123] An electrostatic chuck was produced in the same manner as in Example 1. Make the R of the corner of the convex portion 2 be 0.5mm, and change the abrasive grains of sandblasting, make the arithmetic mean roughness Ra of the groove 4 be 0.3, 0.5, 1.0, 2.0, 2.5, and others are the same as in Example 1 Make an electrostatic chuck. And it evaluated similarly to Example 1. The results are shown in Table 2.

[0124] (table 3)

[0125] Sample No.

Arithmetic mean of groove

Roughness Ra(μm)

Wafer temperature distribution

(℃)

up to saturation temperature

time (seconds)

12

0.3

0.4

2.0

13

0.5

0.5

2.1

14

1.0

0.6

2.3

15

2.0

0.7

2.4

16

2.5

1.2

3.2

[0126] The temperature distribution of the wafers of sample Nos. 12 to 15 in which the arithmetic mean roughness Ra of the bottom surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com