Preparation method of rare earth composite oxides coating Pt-supported catalyst

A technology of oxide coating and rare earth compounding, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., which can solve the problem of easy peeling off of coating and thermal stability of coating In order to achieve the effects of high effective utilization rate, environmental protection and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation of coating: Weigh out 1.08 g of self-made Ce(OH) 3 , 0.32g Y 2 O 3 and 1.78g of citric acid, after mixing, add an appropriate amount of deionized water to dissolve, to obtain a coating liquid. The size is 50mm×25mm×40mm, and the aperture rate is 195cell / in 2 , after the cordierite honeycomb ceramic with a mass of 25.81g is immersed in the coating solution, take it out, blow out the residual liquid in the honeycomb channel, air the cordierite honeycomb ceramic at room temperature until the surface is dry, then dry at 120 ° C for 1 hour, and then put it in a muffle furnace calcined at 500 °C for 4 hours to obtain Ce 0.8 Y 0.2 O 1.9 coating.

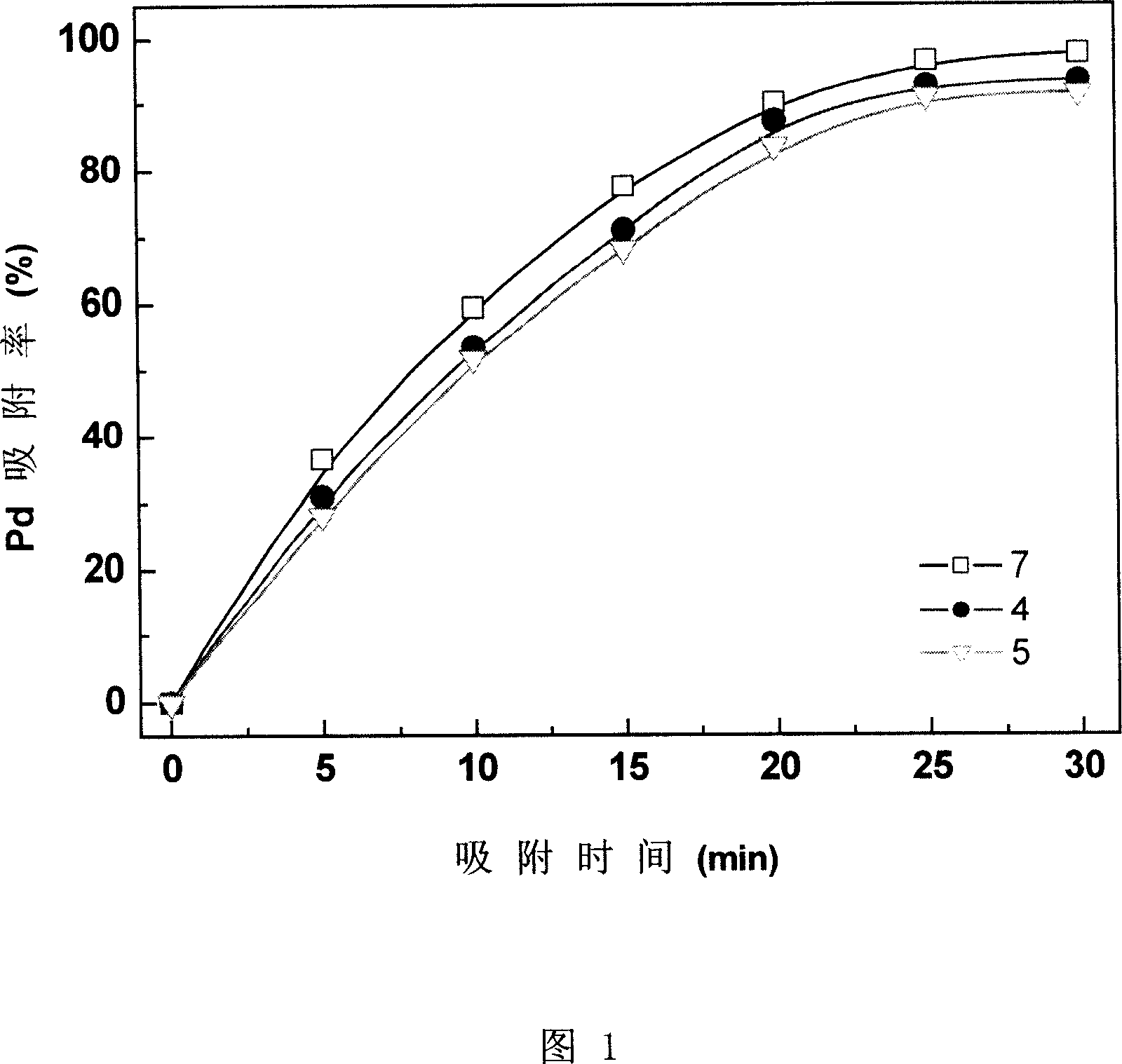

[0019] Pd loading: prepare H with a concentration of 8.9 gPd / L solution 2 PdCl 4 Aqueous solution 100mL is used as the impregnation solution of precious metal active components. Measure 1.5mL H 2 PdCl 4 The aqueous solution is diluted with deionized water until the honeycomb ceramic carrier is just immersed, an...

Embodiment 2

[0022] Preparation of coating: Weigh 1.30g Ce(OH) 4 , 0.36g Y 2 O 3 and 1.97g of citric acid, add an appropriate amount of deionized water after mixing, and stir evenly to obtain a coating solution. The size is 50mm×25mm×40mm, and the aperture rate is 195cell / in 2 , after the cordierite honeycomb ceramic with a mass of 28.66g is immersed in the coating solution, take it out, blow out the residual liquid in the honeycomb channel, air the cordierite honeycomb ceramic at room temperature until the surface is dry, then dry it at 120 ° C for 1 hour, and then put it in a muffle furnace calcined at 500 °C for 4 hours to obtain Ce 0.8 Y 0.2 O 1.9 coating.

[0023] Loading of Pd: measure 1.6 mL of H according to the method of implementation 1 2 PdCl 4 Aqueous solution, adsorption, drying and calcination to obtain Pd / Ce 0.8 Y 0.2 O 1.9 catalyst.

[0024] Performance evaluation of the catalyst: according to the method of Example 1, the T of the catalyst 95 250℃

Embodiment 3

[0026] Preparation of coating: Weigh 1.47g La(OH) 3 , 0.17g CeO 2 and 1.83g of citric acid, after mixing, add an appropriate amount of deionized water to dissolve, to obtain a coating solution. The size is 50mm×25mm×40mm, and the aperture rate is 195cell / in 2 , after the cordierite honeycomb ceramic with a mass of 28.54g is immersed in the coating solution, take it out, blow out the residual liquid in the honeycomb channel, air the cordierite honeycomb ceramic at room temperature until the surface is dry, then dry at 120 ° C for 1 hour, and then put it in a muffle furnace calcined at 500 °C for 4 hours to obtain Ce 0.2 La 0.8 O 1.6 coating.

[0027] Loading of Pd: measure 1.6 mL of H according to the method of implementation 1 2 PdCl 4 Aqueous solution, adsorption, drying and calcination to obtain Pd / Ce 0.2 La 0.8 O 1.6 catalyst.

[0028] Performance evaluation of the catalyst: according to the method of Example 1, the T of the catalyst 95 is 280°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com