Plate blank electroslag furnace

An electroslag furnace and slab technology, applied in the field of slab electroslag furnace, can solve the problems of incomplete controlled rolling equipment, low rolling pressure, steel plate flaw detection, etc. The effect of melting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

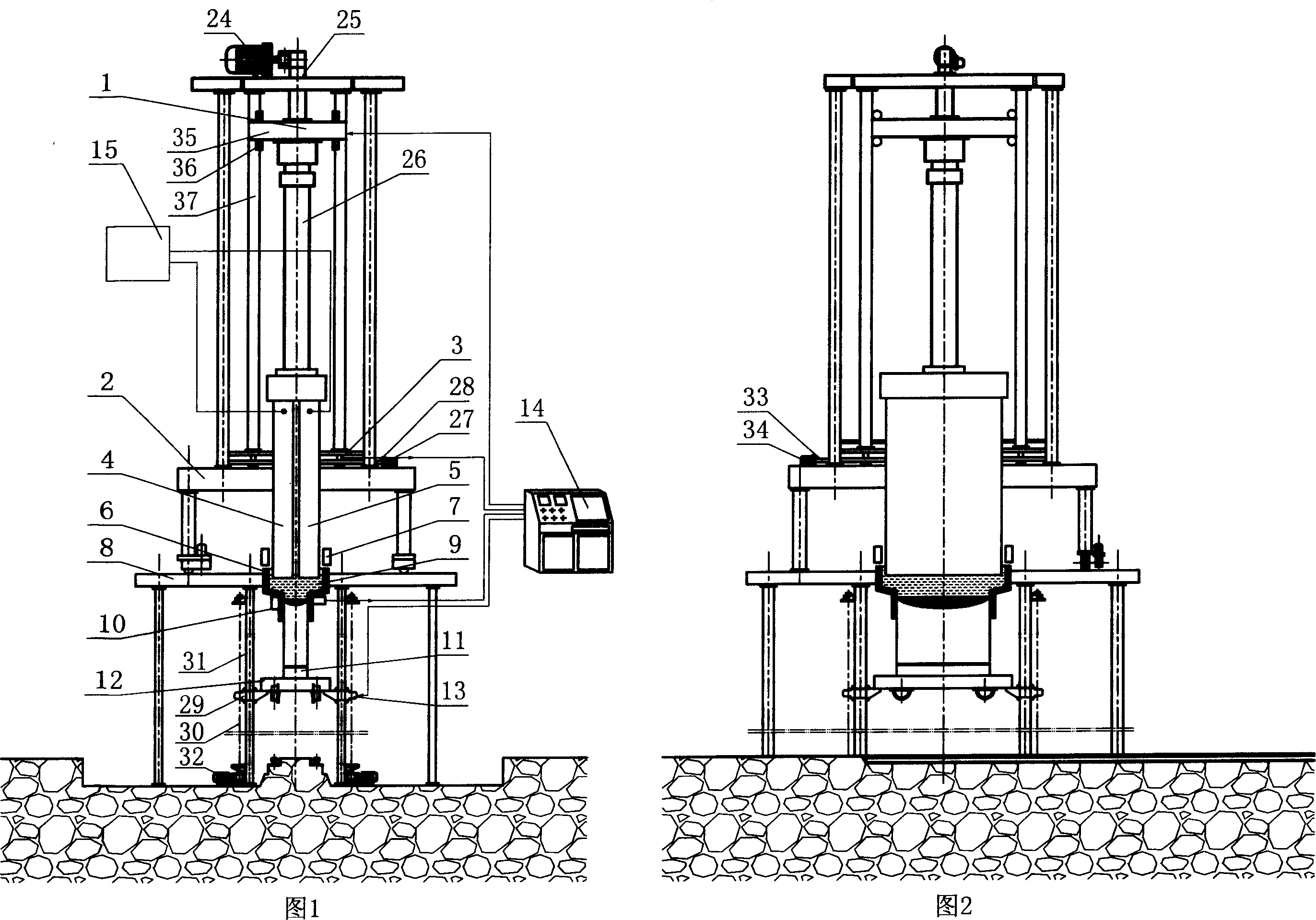

[0046] Embodiment 1: The crystallizer in the present invention adopts a T-shaped crystallizer, the power supply is AC, and the power supply mode of bipolar series. As shown in Figure 1 and Figure 2, it includes an AC power supply 15, an electrode lifting mechanism 1, a rotating frame 2, a load cell 3, an electrode I4, an electrode II5, a T-shaped crystallizer 6, a supporting platform 8, and an ingot pulling mechanism 13, Dummy device 11, ingot transport trolley 12, molten steel liquid level detection device 10 and control system 14, crystallizer 6 is fixed on the support platform 8, on the support platform 8 is fixed a rotating frame 2, the rotating frame 2 can move along the support platform The fixed track on 8 rotates, and an adjustment mechanism is installed on the rotating frame 2, which is used for adjusting the electrode lifting mechanism in the horizontal X and Y directions. The electrode lifting mechanism 1 is placed on the frame platform 18 in the rotating frame 2, an...

Embodiment 2

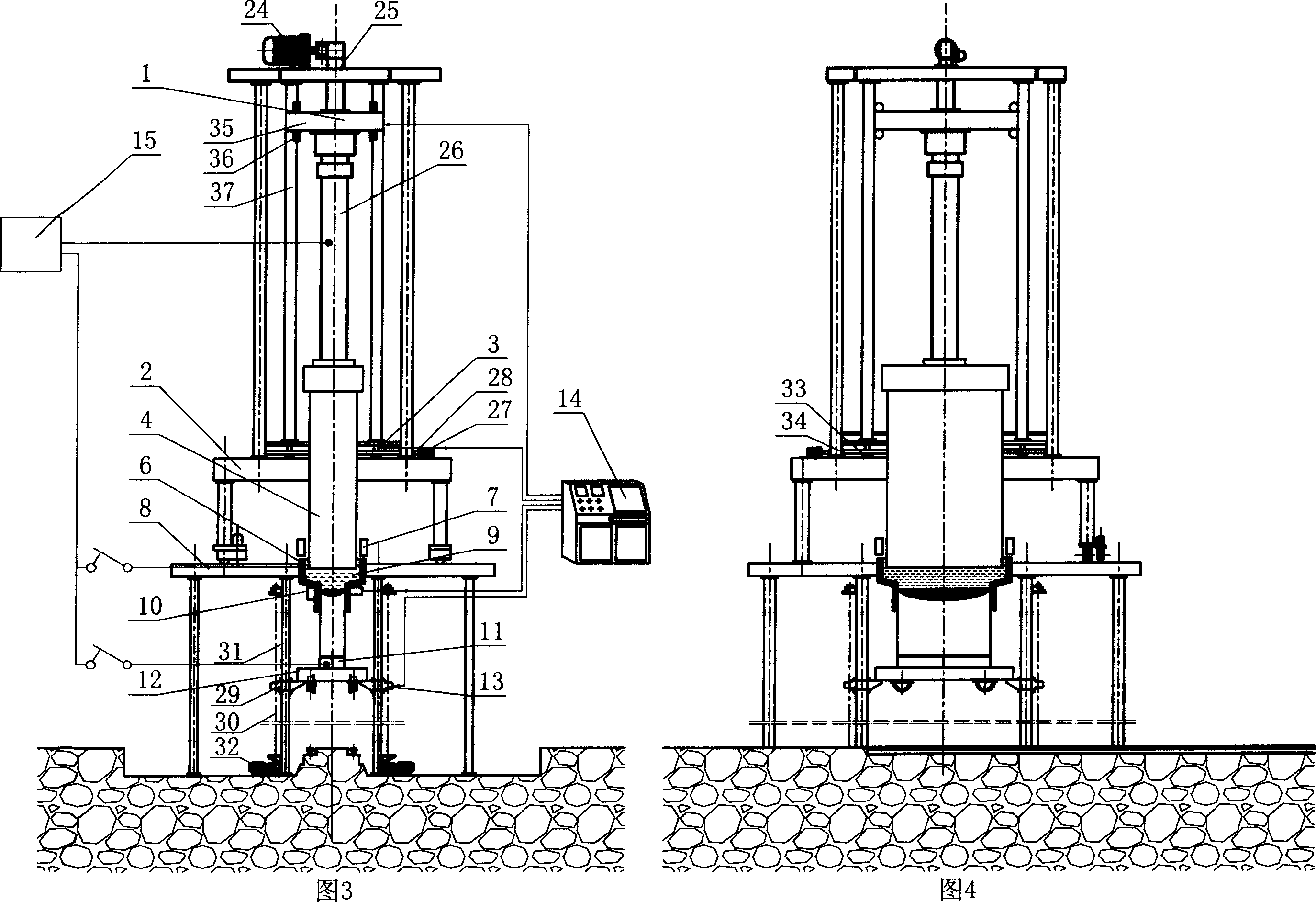

[0063] Example 2: The crystallizer in the present invention adopts a unipolar, T-shaped conductive crystallizer. The T-shaped conductive crystallizer used is a conductive ring placed between the upper part of the crystallizer and the lower part of the crystallizer, and the upper part of the crystallizer and the conductive ring are Insulators are respectively arranged between the lower part of the crystallizer and the conductive ring; the insulator is made of ceramic material, and the conductive ring is made of copper. The power supply is AC, and the power supply mode is single-electrode, T-shaped mold conductive. As shown in Figures 3 and 4, it includes an AC power supply 15, an electrode lifting mechanism 1, a rotating frame 2, a load cell 3, an electrode 14, a mold 6, a supporting platform 8, an ingot pulling mechanism 13, a dummy device 11 and The control system 14, the crystallizer 6 is fixed on the supporting platform 8, the rotating frame 2 is fixed on the supporting pla...

Embodiment 3

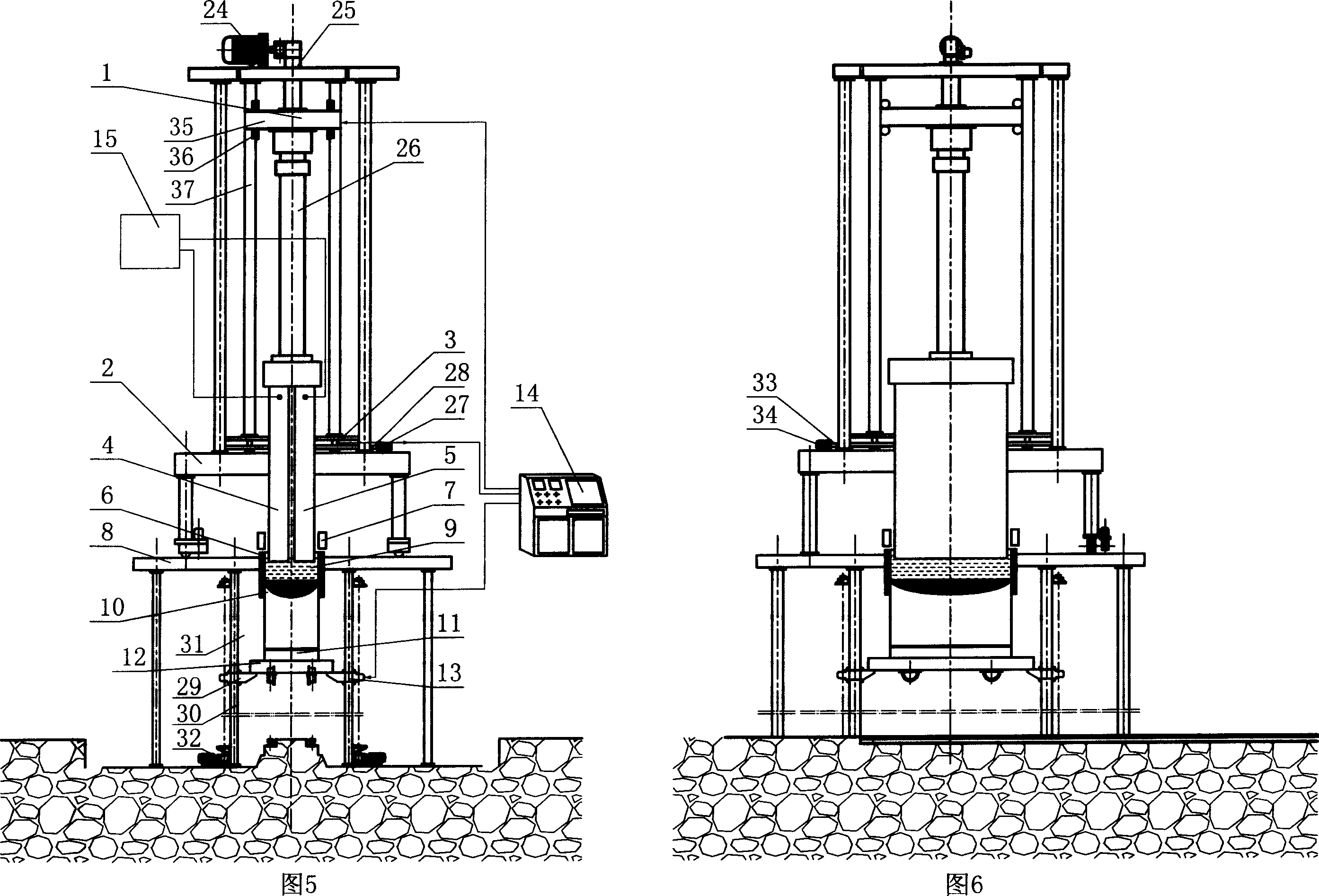

[0066] Example 3: The crystallizer in the present invention adopts a barrel type crystallizer, the power supply is DC, and the bipolar power supply mode is connected in series. As shown in Figures 5 and 6, it includes an AC power supply 15, an electrode lifting mechanism 1, a rotating frame 2, a load cell 3, an electrode I4, an electrode II5, a T-shaped mold 6, a support platform 8, an ingot pulling mechanism 13, The dummy device 11, the ingot transporting trolley 12, the molten steel level detection device 10 and the control system 14, the mold 6 is fixed on the support platform 8, the rotating frame 2 is fixed on the support platform 8, and the rotating frame 2 is mounted on the rotating frame 2. Adjustment mechanism, the electrode lifting mechanism 1 is placed on the frame platform 18 in the rotating frame 2, and a load cell 3 is placed between the contact surface of the electrode lifting mechanism 1 and the frame platform 18, the model is 1-RTNAED9301A, electrode I4 and ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com