Gasification stove with multi nozzle, and gasification method

A gasifier and multi-nozzle technology, which is used in the gasification of granular/powdered fuel, combined combustion mitigation, etc., can solve the problems of short residence time of reactants, unsatisfactory conversion rate of gasification reaction, etc. The effect of prolonging residence time and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

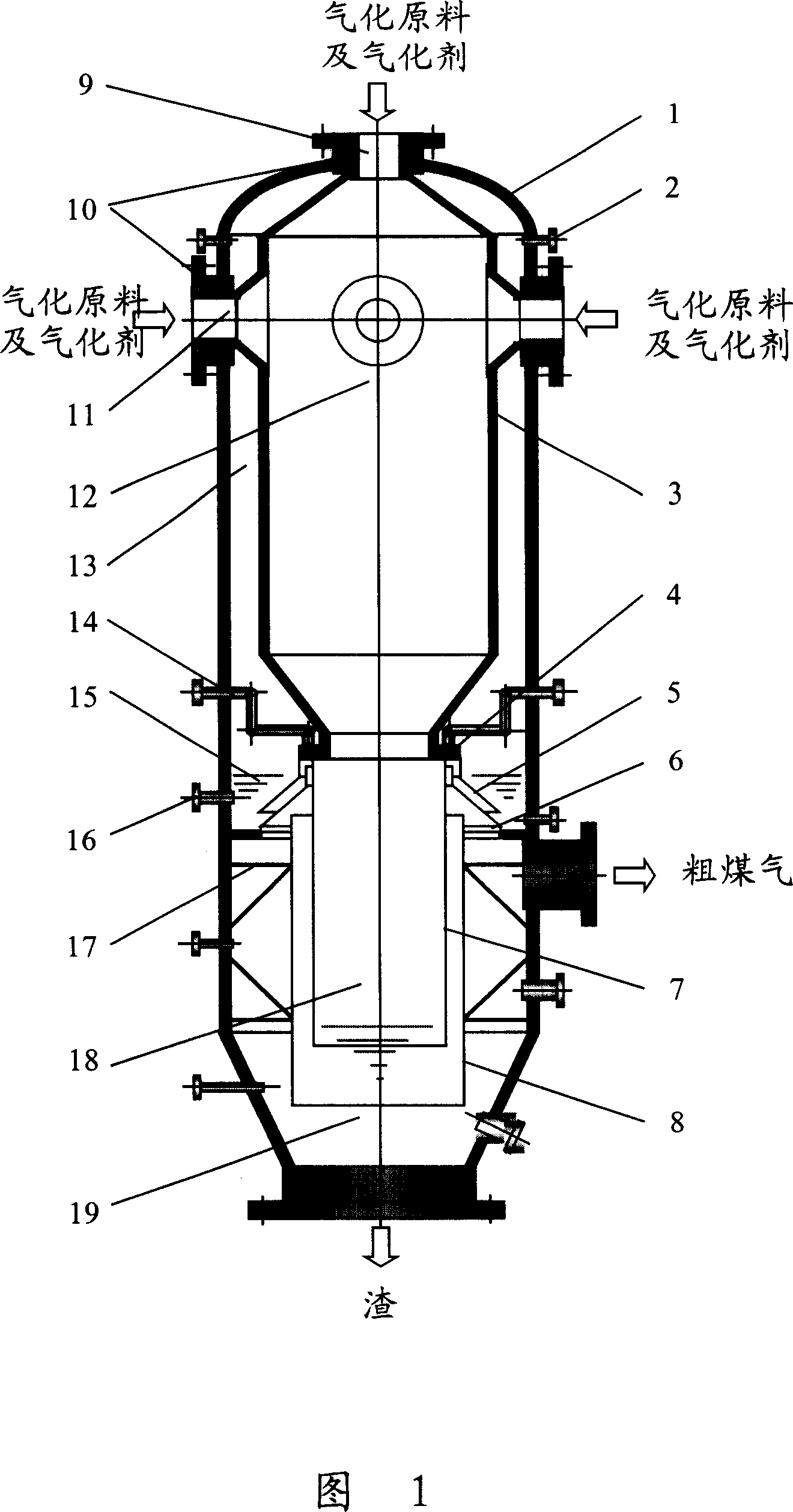

[0032] Figure 1 shows a cantilever-type multi-nozzle gasification furnace, which mainly includes the following components: furnace shell 1, furnace liner 3, chilling ring 4, water seal tank 15, guide tube 7, deflector tube 8, Top nozzle 9, side nozzle 11. The furnace gall, chilling ring, water seal groove, deflector tube, and baffle tube are arranged inside the furnace shell from top to bottom, and the above-mentioned components are preferably arranged coaxially from top to bottom, and are preferably arranged with the The furnace shell is set coaxially. The interior of the furnace is a gasification chamber 12 where the gasification raw material and the gasification agent fully contact to carry out the gasification reaction. The annular space formed between the furnace gall and the furnace shell is a thermal insulation chamber 13, and the space below the water seal groove 15 is a quenching chamber 18 for reactant flow.

[0033] In the gasifier, the top nozzle 9 is arranged on...

Embodiment approach 2

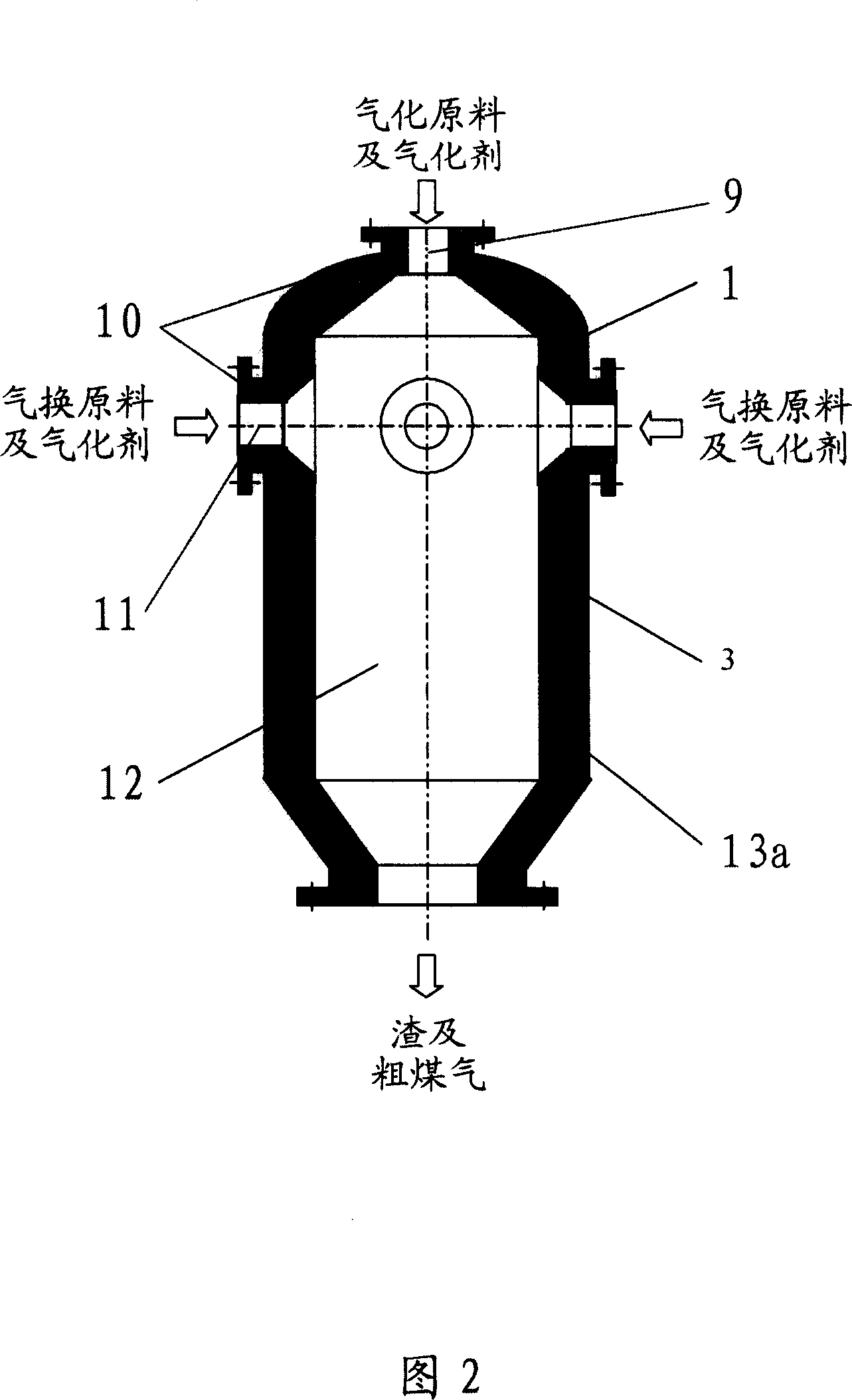

[0046] The gasifier shown in Fig. 2 is another implementation form of the present invention. It is a furnace structure filled with refractory insulation materials. The top nozzle 9 is arranged on the top of the gasification chamber 12, and the central axis of the top nozzle coincides with the central axis of the gasification chamber. The upper part of the gasification chamber 12 is provided with a layer of side nozzles 11 arranged according to the axial deflection angle and radial deflection angle required by the present invention. The refractory insulation material 13a is filled between the furnace 3 and the gasifier shell 1. The upper and lower heads of the furnace 3 and the nozzle installation interface adopt a coil structure, and the straight part adopts a coil structure or a membrane Type water wall structure. Gasification raw materials and gasification agents enter the gasification chamber 12 from the top nozzle 9 and the side nozzle 11 of the gasification furnace, and...

Embodiment approach 3

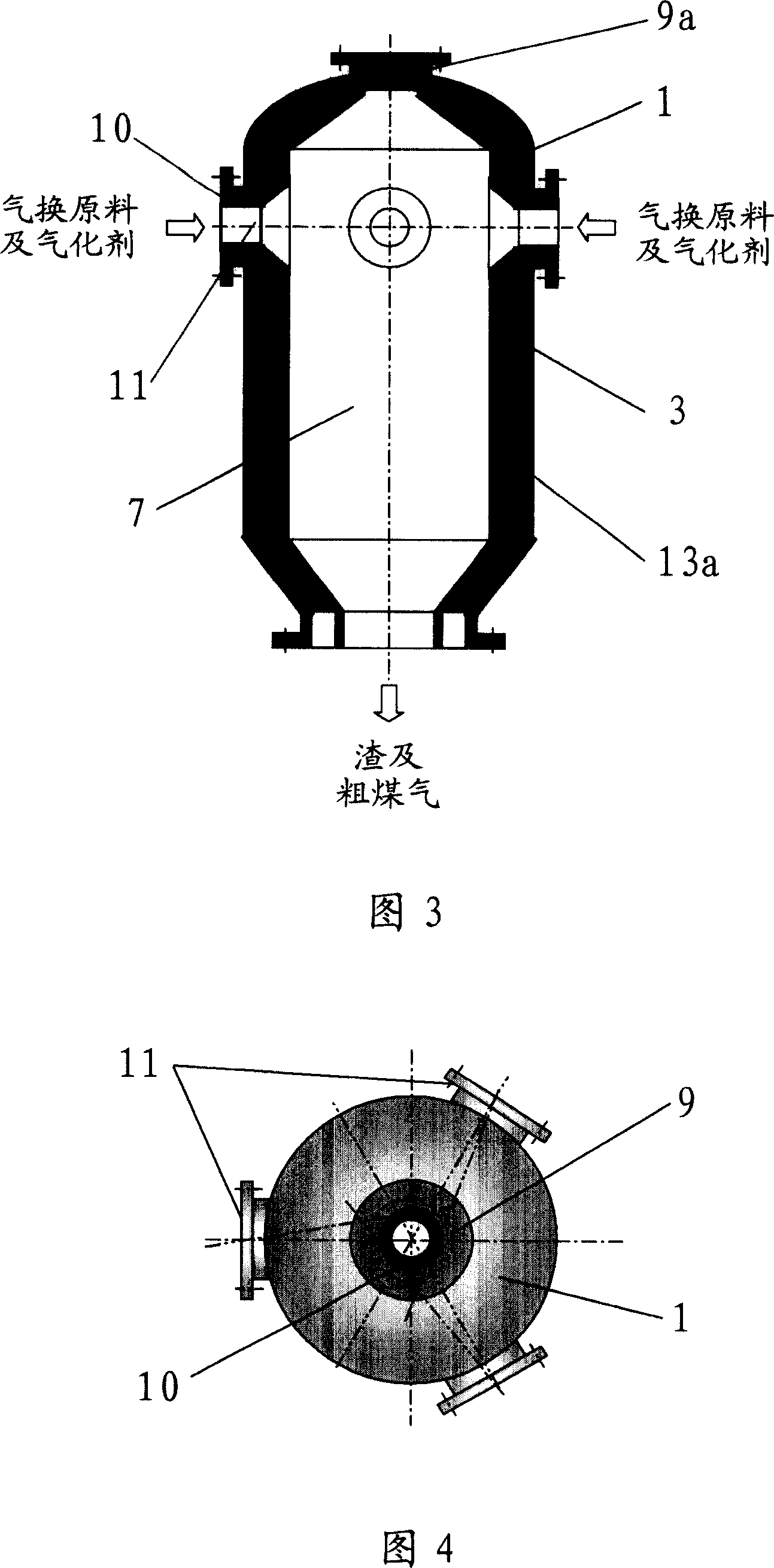

[0048] As shown in Figure 3, in the third embodiment of the present invention, the main structure of the gasification furnace is basically the same as that of the second embodiment, the only difference is that the gasification furnace does not have top nozzles for gasification raw materials and gasification agents , and only the side nozzle 11 is provided. A manhole 9a is provided on the top of the gasification chamber 12 to facilitate installation and maintenance of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com