Process of preparing polymer/imvite nano composite material by surface controlling polymerization

A nano-composite material, montmorillonite technology, applied in the field of polymer preparation, can solve the problems of lack of good correlation in the polymerization reaction, difficult to insert, and difficult to polymerize.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

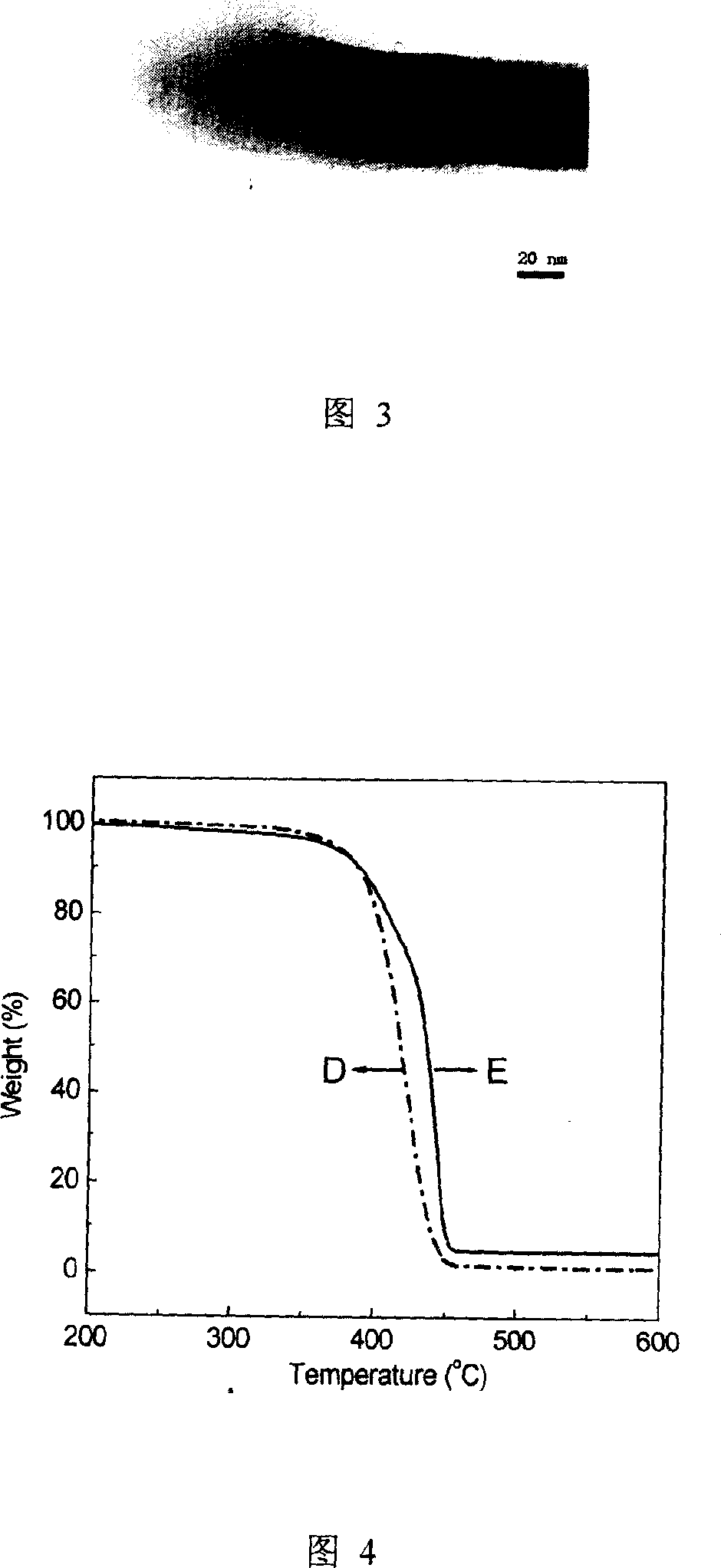

[0022] Embodiment 1. Preparation of polystyrene / montmorillonite nanocomposite

[0023] Synthesis of the reversible addition-fragmentation chain transfer reagent 10-acid-10-dithiobenzyl ester-decyltrimethylammonium bromide:

[0024] Weigh 265 grams (1 mole) of bromoundecanoic acid, dissolve it in 400 grams of tetrahydrofuran, and prepare a solution with a mass concentration of 40%. Take by weighing 540 grams of mass concentration and be that 30% trimethylamine aqueous solution is slowly dripped in 150 grams of sodium hydroxide, and the about 3 moles of trimethylamine gas produced are slowly passed into the above-mentioned bromoundecanoic acid solution, and after reacting for 24 hours, will form Suction filtration of the precipitate. The precipitate was washed and dried in vacuo to obtain 318 g of white powder with a yield of 98%.

[0025] Weigh 324 grams of white powder and 160 grams of liquid bromine (1 mole) prepared by the above method, use 5 grams of phosphorus trichlorid...

Embodiment 2

[0033] Embodiment 2. Preparation of polymethyl acrylate / montmorillonite nanocomposite

[0034] First change the reaction conditions to prepare the reversible addition-fragmentation chain transfer reagent 6-acid-6-dithiobenzyl ester-hexyltrimethylammonium chloride: 164.5 grams (1 mole) of chloro-n-heptanoic acid were dissolved in 1480 grams of acetone In the solution, it is prepared into a solution with a mass concentration of 10%; 900 grams of a mass concentration of 30% trimethylamine aqueous solution is slowly dropped into 200 grams of sodium hydroxide, and about 5 moles of trimethylamine gas produced are slowly passed into the above-mentioned n-heptyl chloride After reacting in acid solution for 24 hours, the resulting precipitate was filtered. The precipitate was washed and vacuum-dried to obtain 221 g of white powder with a yield of 99%.

[0035] Take by weighing 223.5 grams of powder and 240 grams (1.5 moles) of liquid bromine prepared by the above method, 10 grams of p...

Embodiment 3

[0040] Embodiment 3. Preparation of polyacrylic acid / montmorillonite nanocomposite

[0041] Synthesis of reversible addition-fragmentation chain transfer reagent 24-acid-24-dithiobenzyl ester-hexyltrimethylammonium chloride: Weigh 508 grams (1 mole) of iodopentacic acid and dissolve it in 340 grams of ether 180 grams of a mass concentration of 30% trimethylamine aqueous solution is slowly dropped into 50 grams of sodium hydroxide, and about 1 mole of trimethylamine gas is slowly passed into the above-mentioned iodine 20 After reacting in the five-acid solution for 24 hours, the resulting precipitate was filtered; the precipitate was washed and vacuum-dried to obtain 510 g of white powder.

[0042] Take by weighing 567 grams of powder and 208 grams (1.3 moles) of liquid bromine prepared by the above method, use 5 grams of phosphorus trichloride as a catalyst, react at 40 ° C for 18 hours, and remove unreacted bromine in a vacuum to obtain 583 grams of light yellow powder. Yiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com