Composition of nitrile rubber and polyformaldehyde and preparation method thereof

A technology of nitrile rubber and polyoxymethylene, which is applied in the field of the composition of nitrile rubber and polyoxymethylene and its preparation, can solve the problems of not involving the processing performance of the composition, scorch of the rubber material, lack of glue, etc., and achieve the elimination of sticking rollers Phenomenon, eliminate product pad height, improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

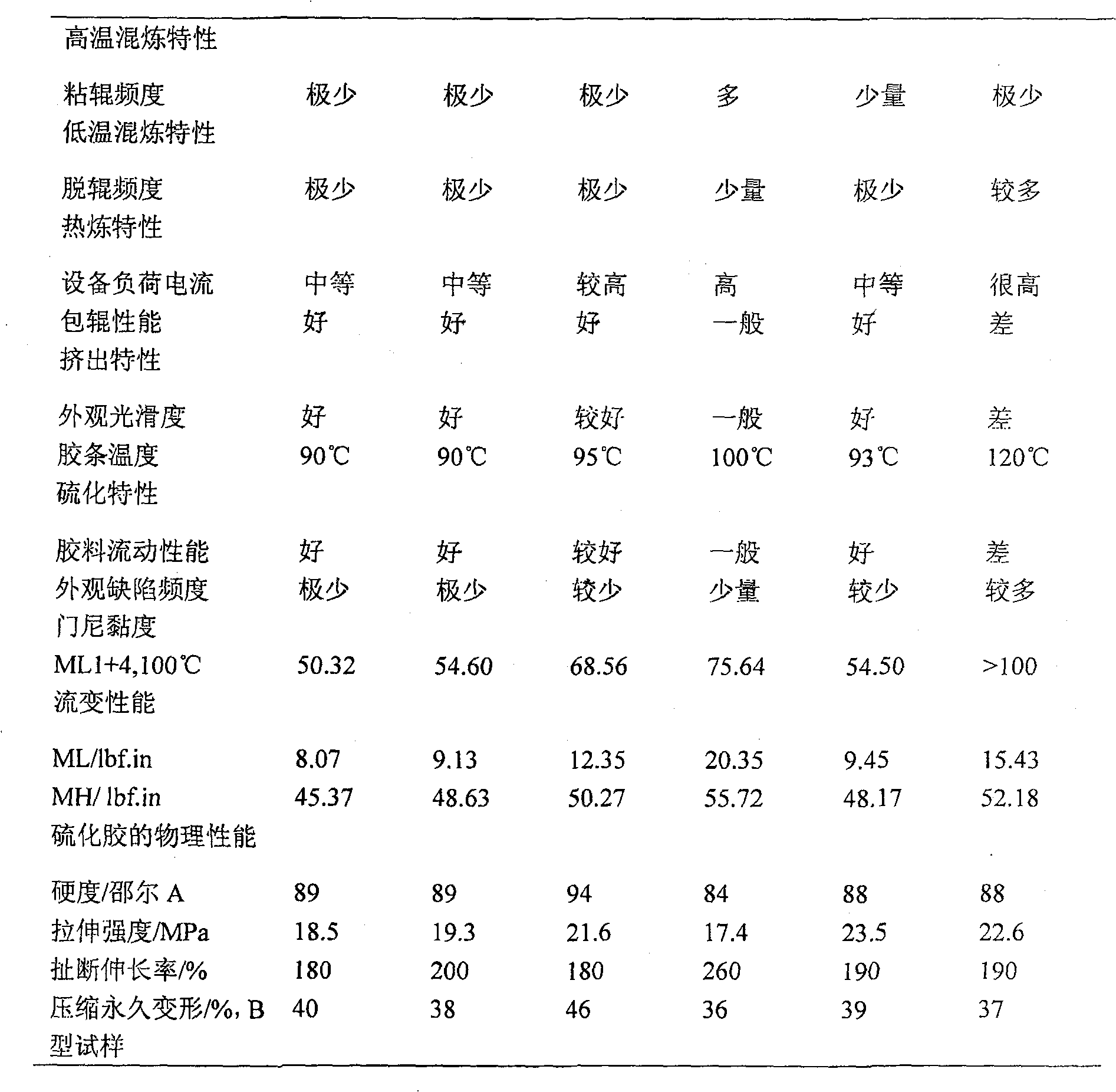

Examples

Embodiment 1

[0029] (1) Preparation of polyoxymethylene masterbatch

[0030] Prepare materials according to the following formula (parts by weight): 300 parts of Perbunan NT 3480 (German Lanxess nitrile rubber, 34% ACN content, ML1+4 is 80 at 100°C), M90-44 (polyoxymethylene copolymer of Japan Polyplastics) 100 2 parts, 2 parts of dicyandiamide, 4 parts of anti-aging agent RD, 4 parts of paraffin.

[0031] First, add anti-aging agent, NBR, and dicyandiamide into the normal temperature open mill and mix evenly at about 60°C for later use; then raise the temperature of the high temperature open mill to 175°C, with a roll distance of 1mm, add POM, paraffin wax, and fully plasticize Evenly, adjust the roll distance to 3mm, add the nitrile rubber containing anti-aging agent that is uniformly mixed, mix evenly at 175°C, adjust the roll distance to 0.5mm, and then pass it thinly for 3 times, and then cool the sheet to obtain polyoxymethylene Masterbatch.

[0032] (2) Preparation of the composit...

Embodiment 2

[0037] (1) Preparation of polyoxymethylene masterbatch

[0038]Prepare raw materials (parts by weight) according to the following formula: 300 parts of N230SH (Japan JSR company, 35% ACN content, ML1+4 is 85 at 100 DEG C), 100 parts of Delrin 100 (U.S. DuPont homopolyoxymethylene), 3 dicyandiamide 6 parts, 6 parts of anti-aging agent RD, 3 parts of paraffin.

[0039] First, add anti-aging agent, NBR, and dicyandiamide into the normal temperature open mill and mix evenly at about 60°C for later use; then raise the temperature of the high temperature open mill to 180°C, the roller distance is 2mm, add POM, paraffin wax, and fully plasticize Evenly, adjust the roll distance to 5mm, add the above-mentioned nitrile rubber containing anti-aging agent that is uniformly mixed, mix evenly at 180°C, adjust to 1.5mm roll distance, and then thin pass 6 times, and the sheet is cooled to obtain polyoxymethylene Masterbatch.

[0040] (2) Preparation of the composition of nitrile rubber and...

Embodiment 3

[0045] The present embodiment is the same as Example 1 except the following features: the preparation of polyoxymethylene masterbatch is prepared according to the following formula (parts by weight): Nipol N-31 (Nipol N-31 (Nipol NBR of Zeon Corporation of Japan, 33% ACN content, at 100° C. ML1+4 is 78) 300 parts, M90-44 (polyoxymethylene copolymer) 100 parts, dicyandiamide 4 parts, anti-aging agent RD 8 parts, paraffin wax 2 parts; the composition of nitrile rubber and polyoxymethylene The preparation is prepared according to the following formula (parts by weight): 27 parts of Perbunan NT 3430 (nitrile rubber from Lanxess Corporation of Germany, 34% ACN content, ML1+4 is 30 at 100°C), 100 parts of POM masterbatch, 3 parts of zinc oxide , 0.5 parts of stearic acid, 1 part of anti-aging agent MB, 55 parts of N330 carbon black, 15 parts of oligoester, 3 parts of dicumyl peroxide, 4 parts of accelerator DTDM, 2.5 parts of accelerator DM, 0.5 parts of accelerator CBS , 0.3 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com