Heat-sensitive digital level transducer

A sensor and thermal technology, applied in the field of thermal digital level sensor, can solve the problems of corrosion of the induction electrode and the influence of conductivity, and achieve the effect of enhancing the anti-interference ability, solving the installation, and improving the stability and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

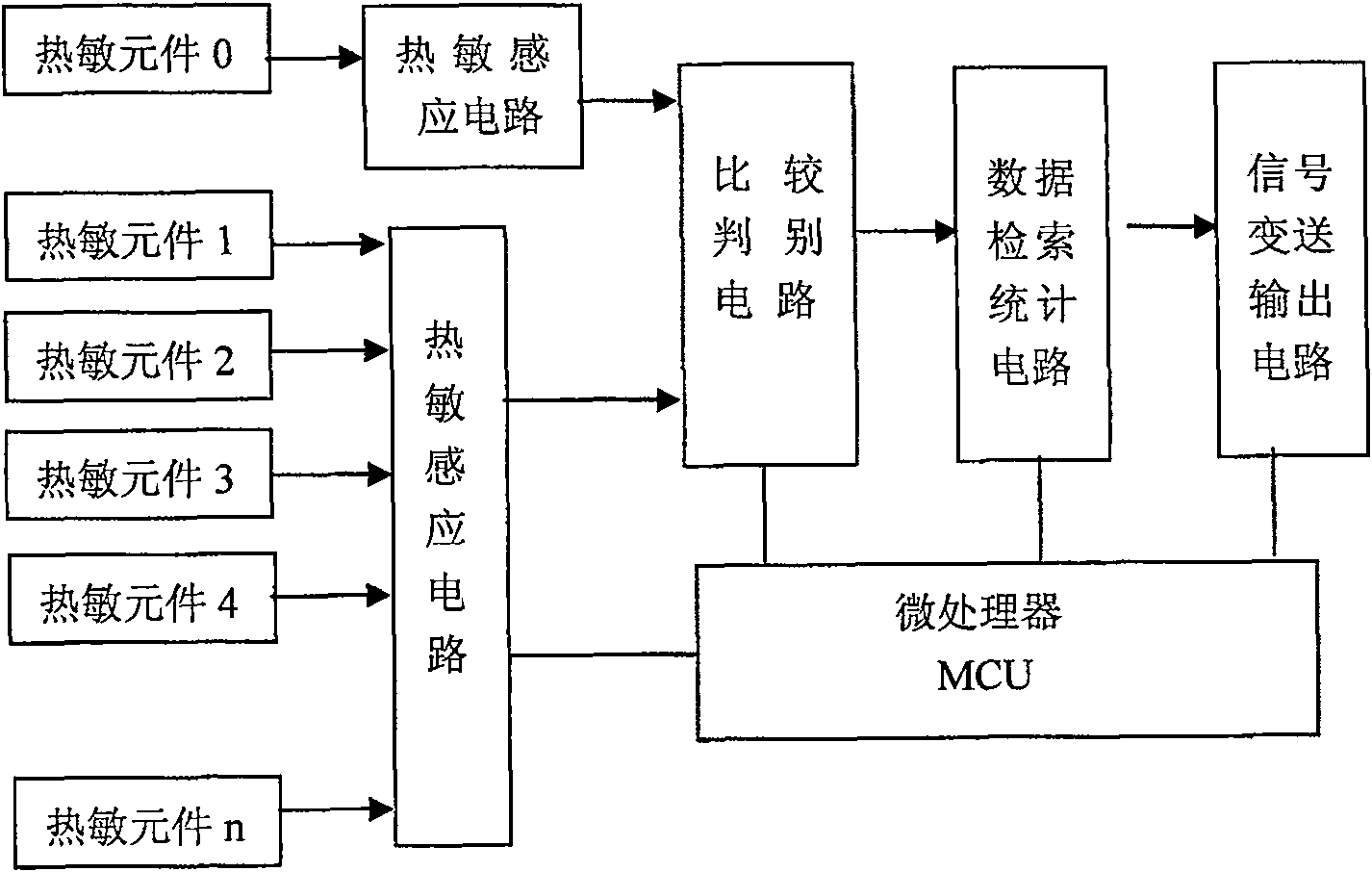

[0026] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, so that those skilled in the art can make the thermal digital level sensor of the present invention according to the specific embodiments, and can also use the thermal digital level sensor of the present invention. The sensitive digital level sensor measures the level and displays it digitally.

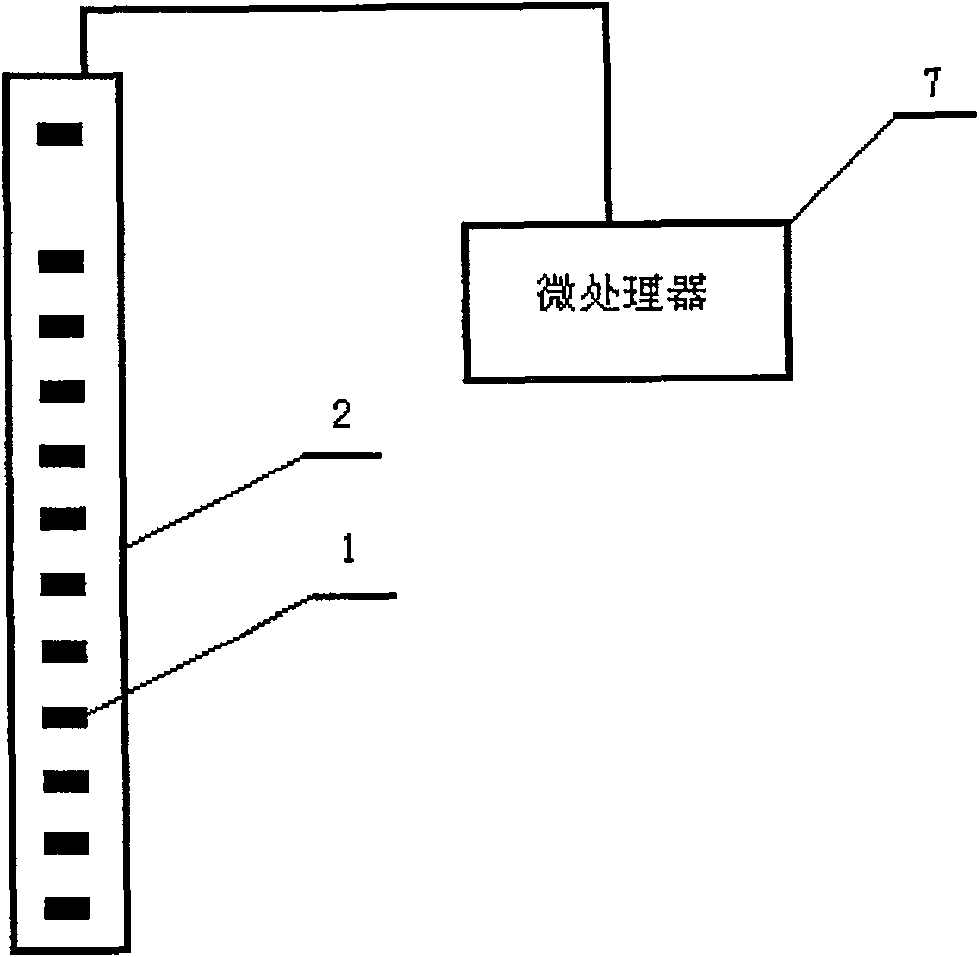

[0027] The structure of the elongated insulator 2 described in the specific embodiment of the present invention can be a rectangular parallelepiped shape, a cylindrical shape, or other types that can be provided with a heat-sensitive element 1 and a heat-sensitive circuit 3, and are made of epoxy resin. The long insulator 2 is connected to the long body of the microprocessor 7 and the power supply.

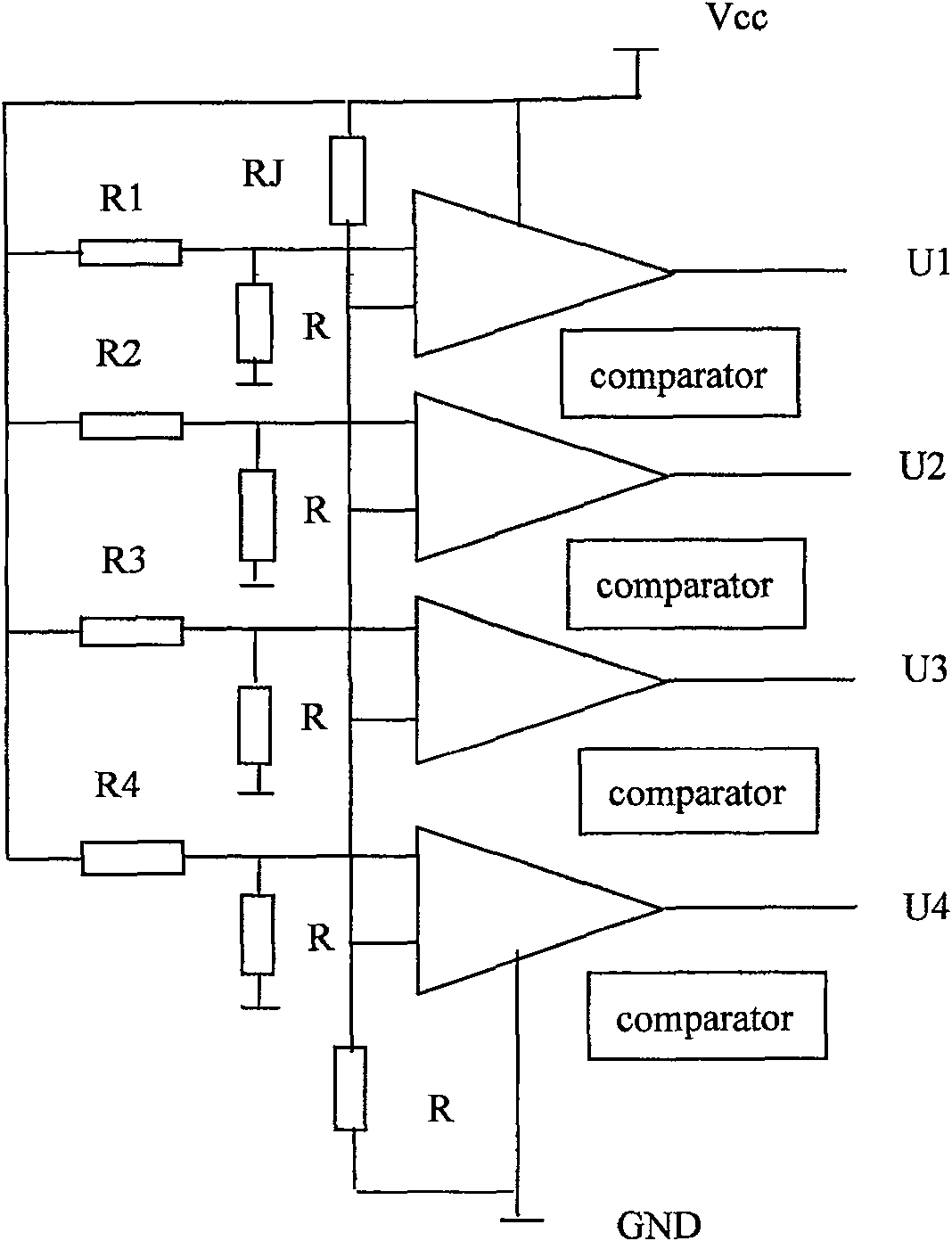

[0028] In the embodiment of the present invention, at least two heat-sensitive elements 1 arranged longitudinally on the elongated insulator 2 desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com