Combined shaping mold

A combined molding and mold technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of metal not being uniformly compressed, compression mold design increases, etc., to achieve less metal cutting, weight reduction, lower machine The effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

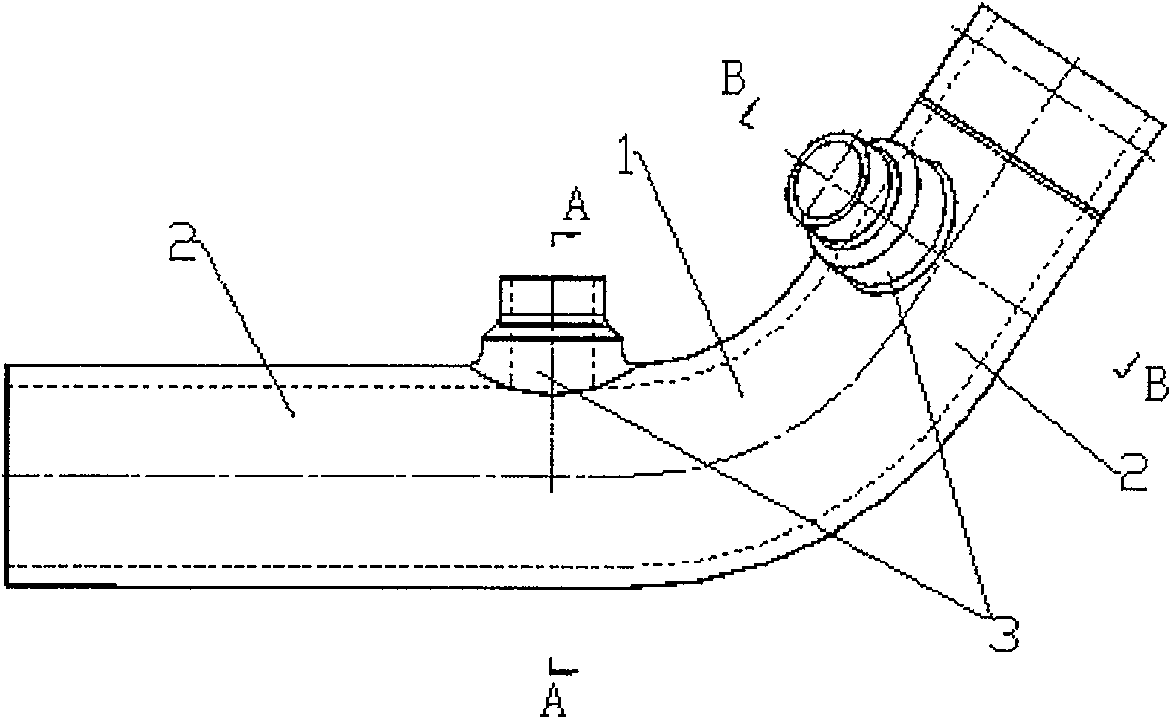

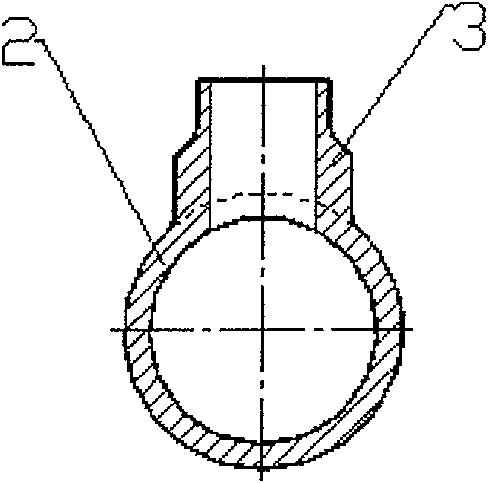

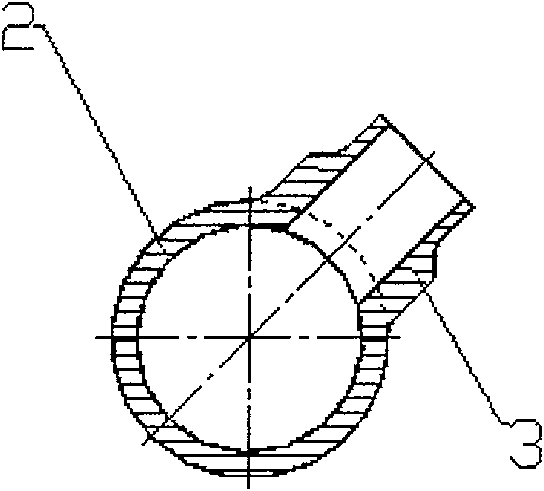

[0039] Embodiment 1: combined forming mold of the present invention is used for making Figure 1~Figure 3 In the hot section elbow of the reactor main pipe shown, the bending radius R of the curved section 1 on the pipe body of the elbow is R=1.5D, and a straight pipe section 2 is arranged at both ends of the curved section 1, and the straight pipe section 2 is close to the curved section 1 The two nozzles 3 are arranged at the position, and the two nozzles 3 are respectively arranged on the straight pipe section 2 at both ends of the curved section 1, the axes of the two nozzles 3 are not on the same plane, and D is the outer diameter of the pipe. The pipe body adopts the integrated structure of the integral forging made of ultra-low carbon stainless steel, and the straight pipe blank is made according to the structural shape of each part of the pipe body. Adopt the combined forming mold of the present invention to process the pipe blank, the filling rate of the core mold fil...

Embodiment 2

[0040] Embodiment 2: combined forming mold of the present invention is used for making Figure 4 In the hot section elbow of the reactor main pipe shown, the bending radius R of the curved section 1 on the pipe body of the elbow is R=1.5D, and a straight pipe section 2 is arranged at both ends of the curved section 1, and the straight pipe section 2 is close to the curved section 1 The two nozzles 3 are arranged at the position, and the two nozzles 3 are respectively arranged on the straight pipe section 2 at both ends of the curved section 1, the axes of the two nozzles 3 are on the same plane, and D is the outer diameter of the pipe. The pipe body adopts the integrated structure of the integral forging made of ultra-low carbon stainless steel, and the straight pipe blank is made according to the structural shape of each part of the pipe body. Adopt the combined forming mold of the present invention to process the pipe blank, the filling rate of the core mold filling the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com