Method for preparing lanthanum subcarbonate nana-/micro-crystal by double hydrolysis regulation

A technology of sodium lanthanum carbonate and double hydrolysis, applied in chemical instruments and methods, rare earth metal compounds, inorganic chemistry, etc., can solve the problems of rational application of unfavorable environmental protection resources, difficult control of product morphology, and high production cost, and is convenient for industrialization. The operation and product processing are convenient and concise, and the environmental pollution is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: prepare helical rod-shaped lanthanum hydroxycarbonate

[0025] (1) Add 1×10 -3 mol of La 2 o 3 , 3×10 -2 mol glycine, after adding deionized water to make the filling degree of the reactor reach 60-80%, seal the reactor;

[0026] (2) Transfer the reaction kettle to a temperature-controlled furnace, control the reaction temperature to 200° C., and heat at this temperature for 8, 15, 24, 32, and 48 hours respectively.

[0027] (3) After the reaction was completed, the reactor was taken out and cooled to room temperature naturally.

[0028] (4) Take out the precipitate obtained in the reaction, wash it three times with deionized water and absolute ethanol alternately, and centrifuge after each washing to obtain the desired product.

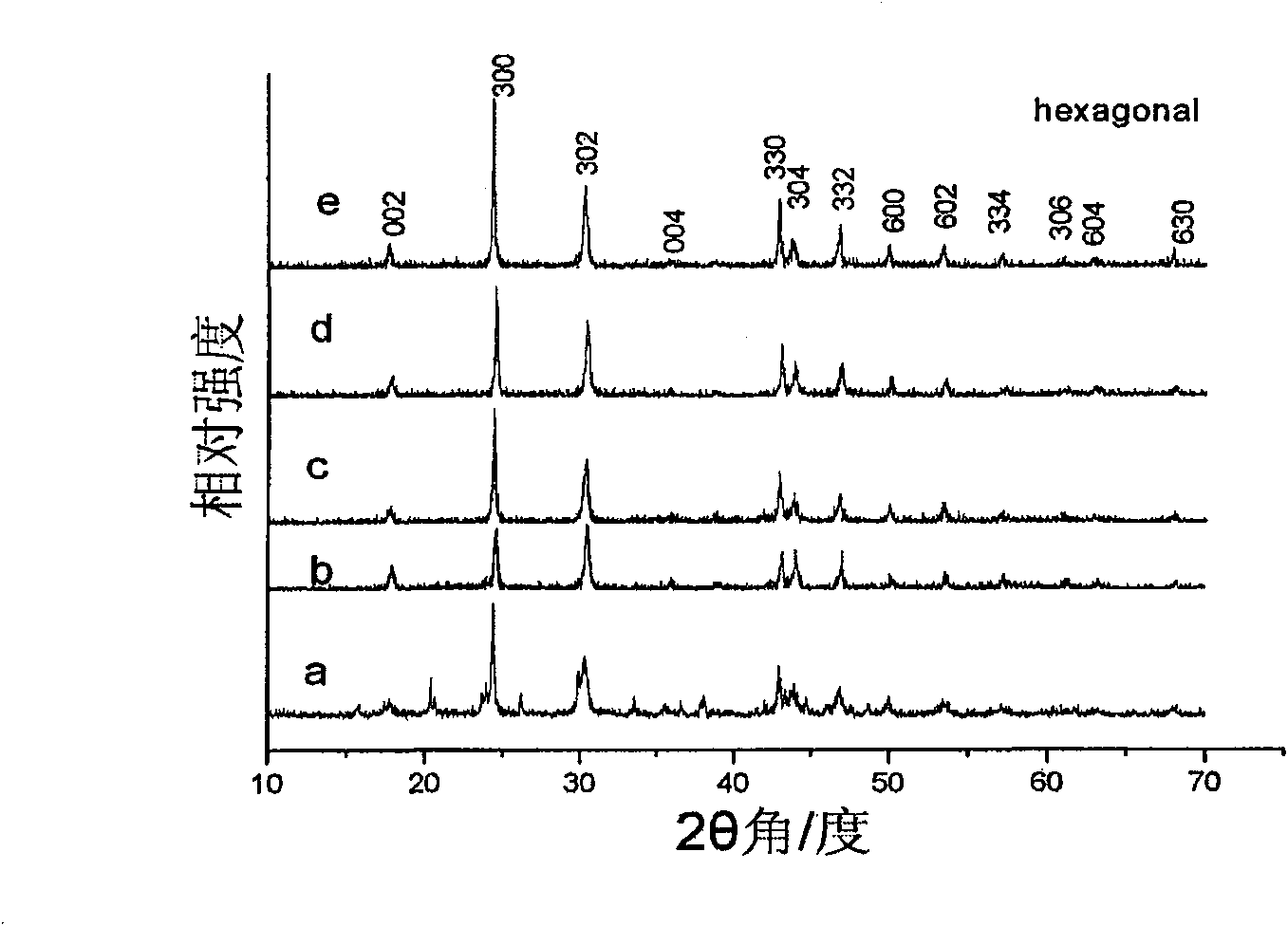

[0029] figure 1 The X-ray powder diffraction patterns (a-e are 8, 15, 24, 32, 48h) of the products obtained at different reaction times are given respectively. It can be seen that the crystal form of the obtained product i...

Embodiment 2

[0030] Embodiment 2: prepare round cake shape and spiral bar shape lanthanum carbonate basic

[0031] (1) Add 1×10 -3 mol of La 2 0 3 , 3×10 -2 mol glycine, after adding deionized water to make the filling degree of the reactor reach 60-80%, seal the reactor;

[0032] (2) Transfer the reactor to a temperature-controlled furnace, and control the reaction temperature to 160, 180, and 200° C. for 32 hours, respectively.

[0033] (3) After the reaction was completed, the reactor was taken out and cooled to room temperature naturally.

[0034] (4) Take out the precipitate obtained in the reaction, wash it three times with deionized water and absolute ethanol alternately, and centrifuge after each washing to obtain the desired product.

[0035] image 3 Shown are the SEM photos of the products generated by controlling the reaction temperature at 160, 180, 200, and 220°C (A-D) for a reaction time of 32 hours. It can be seen from the figure that the product obtained with the inc...

Embodiment 3

[0036] Embodiment 3: prepare helical rod-shaped lanthanum hydroxycarbonate

[0037] (1) Add 1×10 -3 mol of La 2 o 3 , 4×10 -2 mol glycine, after adding deionized water to make the filling degree of the reactor reach 60-80%, seal the reactor;

[0038] (2) Then, the reaction kettle was transferred to a temperature-controlled furnace, and the reaction time was controlled to be 32 hours, and the reaction temperatures were respectively controlled to be 160, 180, and 200° C. under the reaction time.

[0039] (3) After the reaction was completed, the reactor was taken out and cooled to room temperature naturally.

[0040] (4) Take out the precipitate obtained in the reaction, wash it three times with deionized water and absolute ethanol alternately, and centrifuge after each washing to obtain the desired product. The SEM photo of the product shows that the product is in the shape of a micron-sized spiral rod. The average length of the product obtained at 160° C. is about 1.5 μm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com