Process for preparing 4-vinyl epoxycyclohexane

A technology of vinyl cyclohexene and epoxy ring, applied in the direction of organic chemistry, can solve the problems of low product content, low product selectivity, and many by-products, and achieve high economic value, high yield, and good quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: The preparation method of 4-vinyl epoxy cyclohexane, the main raw materials for preparing 4-vinyl epoxy cyclohexane are 4-vinyl cyclohexene and hydrogen peroxide.

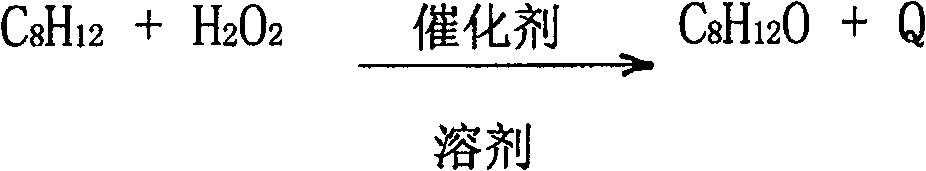

[0037] The chemical formula for preparing 4-vinyl epoxycyclohexane is:

[0038]

[0039] In the above formula, Q is heat.

[0040] The weight percent of the raw material of preparing 4-vinyl epoxy cyclohexane is:

[0041] 4-Vinylcyclohexene 24%, H 2 o 2 15%, catalyst 0.8%, solvent 60.2%.

[0042] The preparation method of 4-vinyl epoxy cyclohexane comprises the following technical process:

[0043] a. Measure 4-vinylcyclohexene, catalyst, and solvent in proportion, place them in the reactor, and stir;

[0044] b. Slowly add hydrogen peroxide, and control the reaction temperature at 50°C. After the hydrogen peroxide has completely reacted, cool the solution to 25°C;

[0045] c, filter the cooled solution to separate the catalyst;

[0046] d, carry out a rectification to the solution after...

Embodiment 2

[0048] Example 2: The preparation method of 4-vinyl epoxy cyclohexane, the main raw materials for preparing 4-vinyl epoxy cyclohexane are 4-vinyl cyclohexene and hydrogen peroxide.

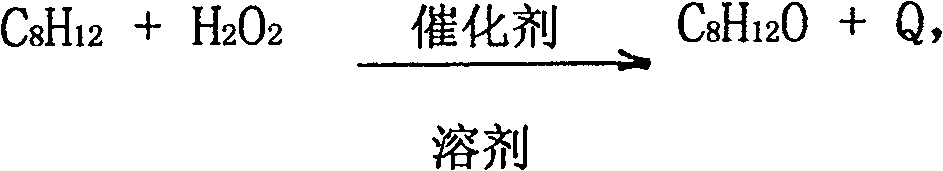

[0049] The chemical formula for preparing 4-vinyl epoxycyclohexane is:

[0050]

[0051] In the above formula, Q is heat.

[0052] The weight percent of the raw material of preparing 4-vinyl epoxy cyclohexane is:

[0053] 4-Vinylcyclohexene 21%, H 2 o 2 17%, catalyst 0.7%, solvent 61.3%.

[0054] The preparation method of 4-vinyl epoxy cyclohexane comprises the following technical process:

[0055] a. Measure 4-vinylcyclohexene, catalyst, and solvent in proportion, place them in the reactor, and stir them;

[0056] b. Add hydrogen peroxide slowly, and control the reaction temperature at 65°C. After the hydrogen peroxide has completely reacted, cool the solution to 23°C;

[0057] c, filter the cooled solution to separate the catalyst;

[0058] d, carry out a rectification to the solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com