Catalyst for synthesizing methanol and preparation method thereof

A technology for synthesizing methanol and catalysts, applied in catalyst activation/preparation, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of high heat sensitivity and rapid activity decline, and achieve the effects of high methanol selectivity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

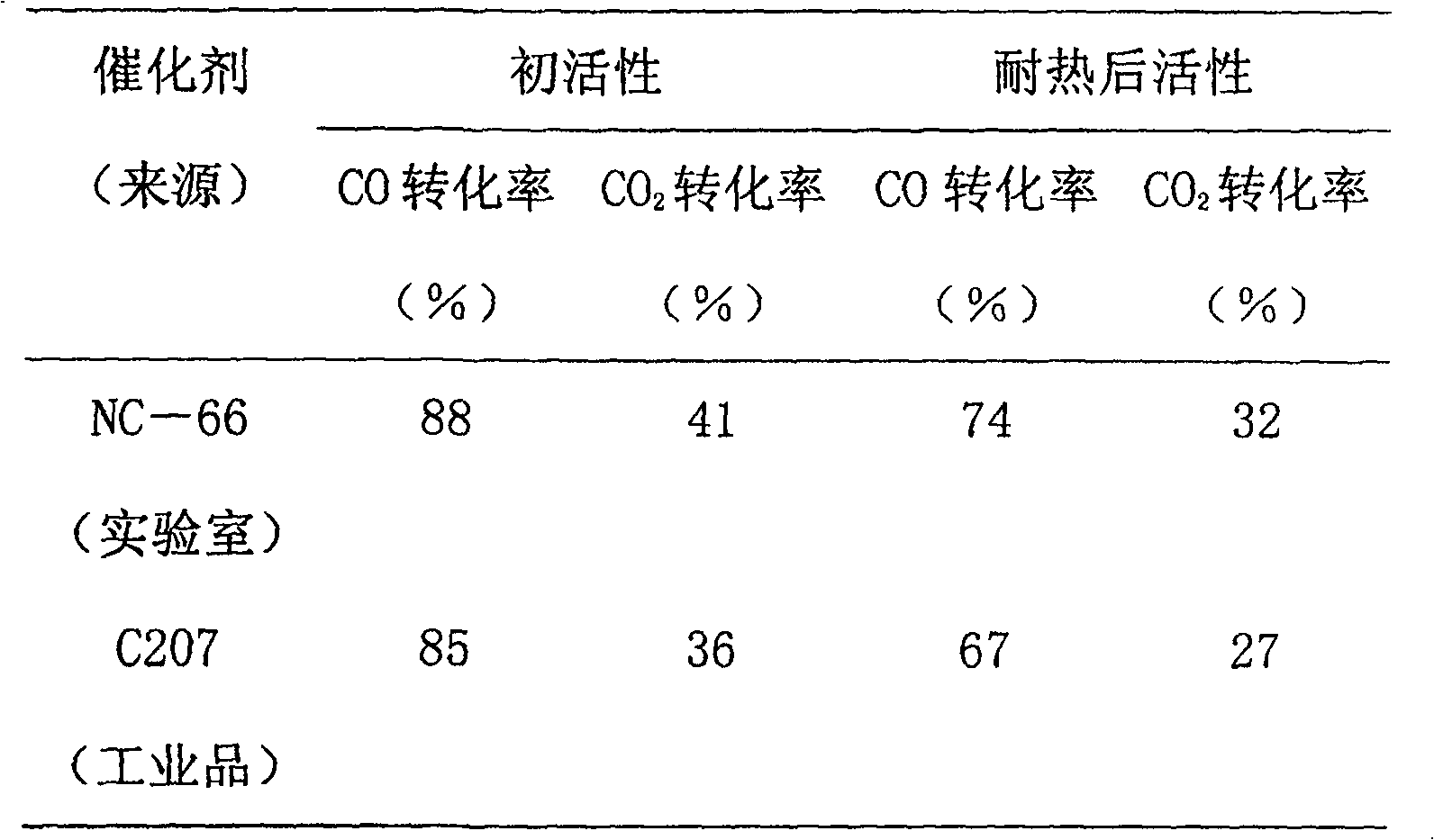

Examples

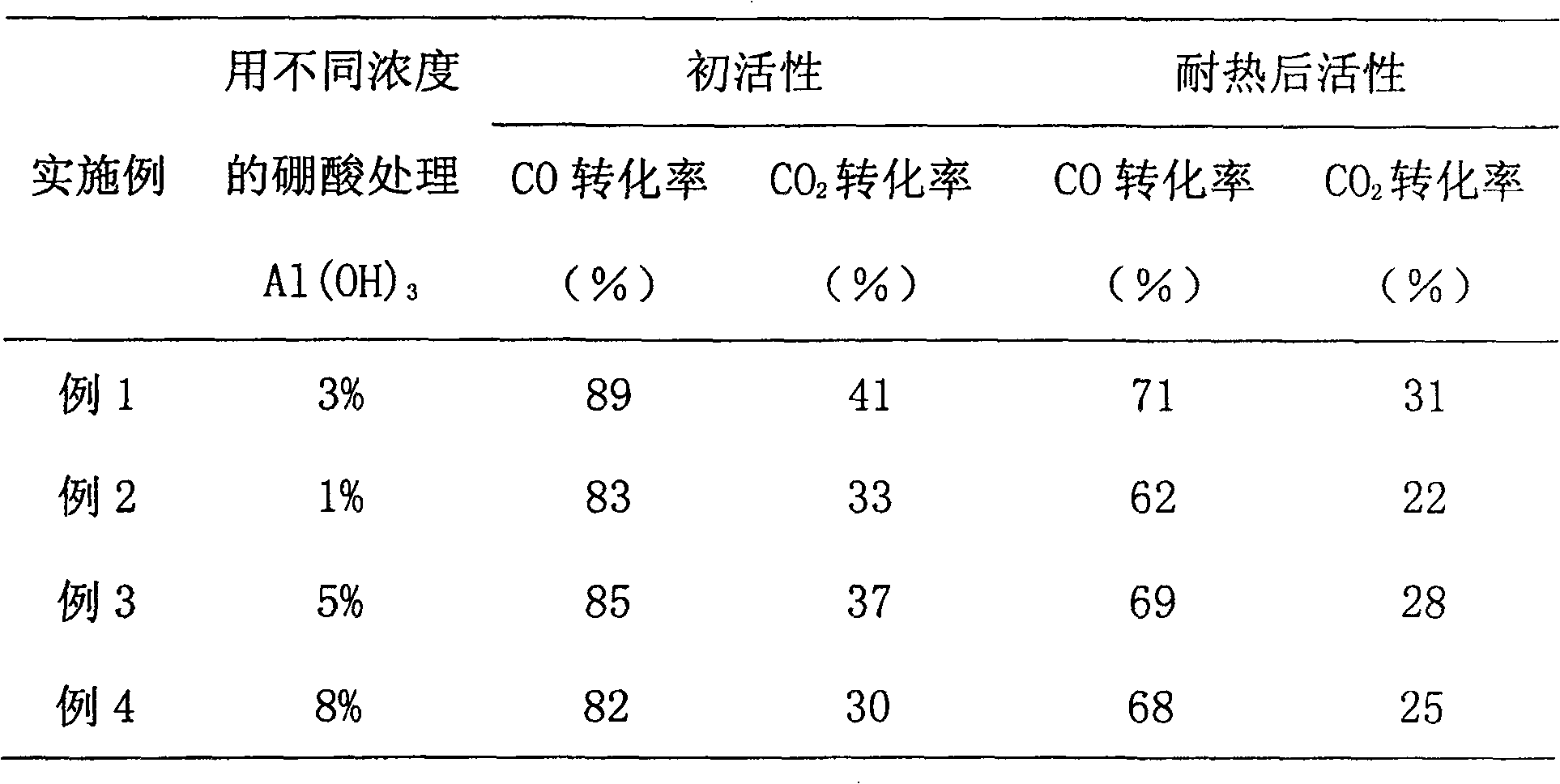

Embodiment 1

[0018] (1) With mixed solution. Take 1.0M Cu(NO 3 ) 2 750ml, 1.0M Zn(NO 3 ) 2 750ml is mixed in a 2000ml beaker.

[0019] (2) neutralization. Take 3000ml 0.25M Na 2 Put the CO solution in a 5000ml beaker and heat it to 80°C, and add the (1) mixture to Na at a rate of 200ml / min under stirring 2 CO 3 In the solution, when the pH=7.2 is the end point, stop heating and stirring after aging for 0.5 hours.

[0020] (3) Washing. After (2) precipitation, wash the precipitate with tilting method (using 70°C deionized water) until there is no NO 3 - .

[0021] (4) Put 12.5g Al(OH) 3 The powder is first activated with 3% boric acid solution, then poured into the precipitate and stirred for 20 minutes.

[0022] (5) Suction filtration, drying at 110°C, crushing, and calcining at 350°C for 2 hours.

[0023] (6) Tablet molding. Add a small amount of graphite and water to the mixed oxide obtained in (4), mix well, and press into tablets. Crushed and sieved into 16 mesh to 40 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com