Steel-scoria and mine-scoria cement by using steel-scoria ball milled waste mud and its production method

A technology for steel slag tailings and slag cement, applied in the field of building materials, can solve the problems that steel slag cement is difficult to be widely recognized and affects the volume stability of steel slag cement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0010] 2. Preparation method of steel slag tailings slag cement

[0011] The preparation method of steel slag tailings slag cement of the present invention, the steps are as follows:

[0012] (1) Use the steam produced by waste heat boilers in iron and steel enterprises as a heat source to heat-treat wet steel slag tailings at a temperature of 100°C-120°C, keep the water content of steel slag tailings below 4%, and break large pieces of gypsum to below 10mm ; Send the crushed steel slag tailings into the ball mill for grinding until the Blaine specific surface area is 450-470m 2 / kg;

[0013] (2) Grind silicate clinker, blast furnace slag and natural gypsum to Blaine specific surface area of 450-470m 2 / kg;

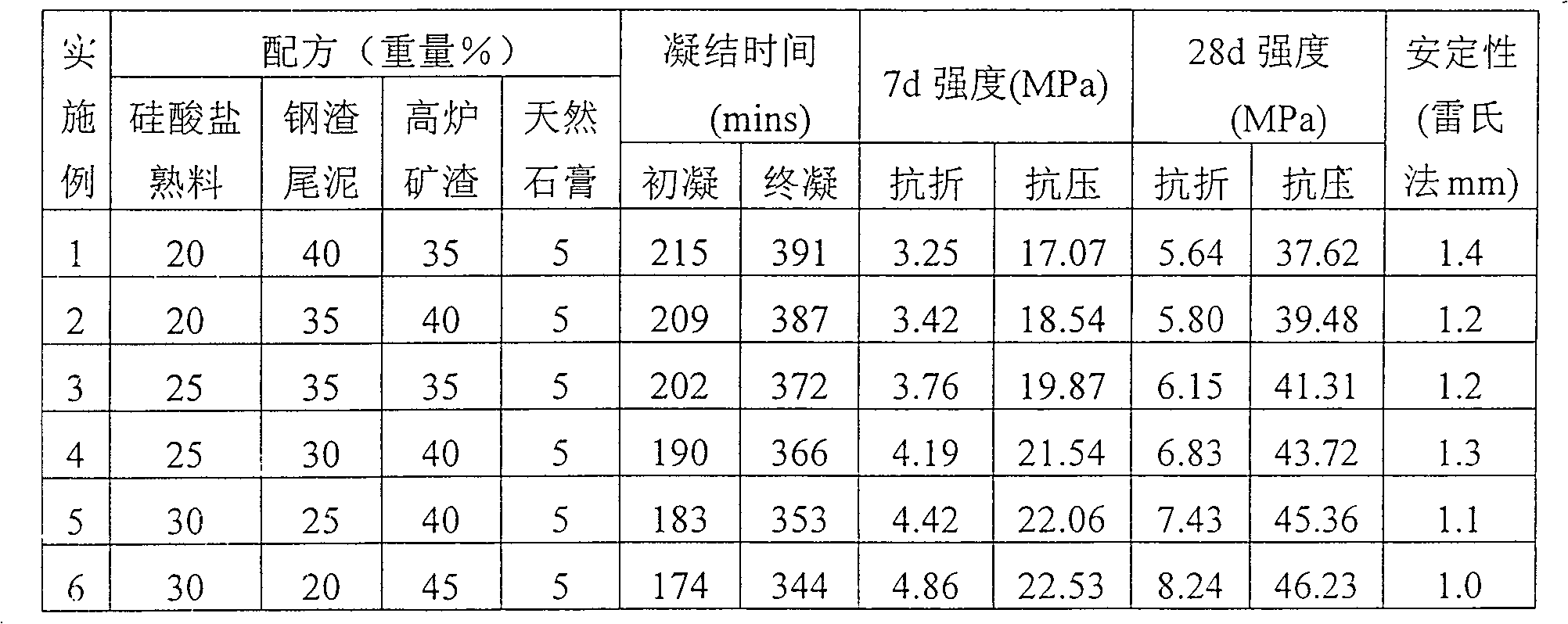

[0014] (3) The steel slag tailings processed in step (1) and the silicate clinker, blast furnace slag and natural gypsum processed in step (2) are dosed according to the following weight ratio: 20% to 40% of steel slag tailings, blast furnace slag 35% to 45%, silica...

specific Embodiment approach

[0020] The present invention will be further described below in conjunction with the examples, but not limited thereto.

[0021] The steel slag tailings used in the examples are the sludge produced by the converter steelmaking steel slag after wet ball mill grinding, water washing and iron selection, the silicate clinker is 525# ordinary Portland cement clinker, and the blast furnace slag is Blast furnace slag treated by granulation and water quenching, natural gypsum is ordinary natural dihydrate gypsum. The chemical composition of each raw material is shown in Table 1.

[0022] Table 1 raw material chemical composition table (mass percentage %)

[0023] raw material

Embodiment 1

[0024] Embodiment 1: steel slag tailings slag cement and preparation method thereof, the steps are as follows:

[0025] (1) Use the steam produced by the waste heat boiler of the iron and steel enterprise as a heat source to heat-treat the wet steel slag tailings at a temperature of 105°C, so that the water content of the steel slag tailings is about 3%, and the large pieces of gypsum are broken to below 10mm; The final steel slag tailings are sent to a ball mill for grinding until the Blaine specific surface area is 460m 2 / kg;

[0026] (2) Grind silicate clinker, blast furnace slag and natural gypsum to Blaine specific surface area of 460m 2 / kg;

[0027] (3) The steel slag tailings, silicate clinker, blast furnace slag and natural gypsum processed through steps (1) and (2) are proportioned according to the following weight ratio: 40% of steel slag tailings, 35% of blast furnace slag, silicate 20% of clinker and 5% of natural gypsum are mixed in a mixer. Product proper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com