Admixture of active powder of ball milling steel slag tailing slurry and application thereof in preparing concrete

A technology for steel slag tailings and admixtures, applied in the fields of environmental protection and building materials, can solve problems such as insufficient resources of concrete admixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0009] The preparation method of the ball mill steel slag tailings active powder admixture of the present invention, the steps are as follows:

[0010] (1) Break the large ball mill steel slag tailings cake with high water content to 50-100cm, and let the water content of the ball mill steel slag tailings reach 9-10%.

[0011] (2) Use a jaw crusher to crush the ball milled steel slag tailings obtained in step (1) to 9 to 10 cm, and perform drying and heat treatment at a temperature of 100° C. to 120° C. to reduce the moisture content of the ball milled steel slag tailings to below 4%. , cooled to 28 ~ 30 ℃.

[0012] The above-mentioned drying heat treatment at a temperature of 100° C. to 120° C. uses the steam produced by a metallurgical waste heat boiler as a heat source.

[0013] (3) Crushing the natural gypsum to 5-10 mm, taking natural gypsum according to 5-8%wt of the ball mill steel slag tailings weight, and sending it into a ball mill for grinding with the crushed ball...

specific Embodiment approach

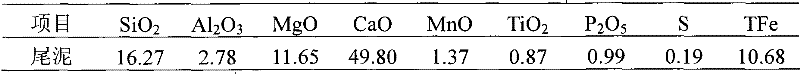

[0026] The present invention will be further described below in conjunction with the examples, but not limited thereto. The ball mill steel slag tailings used in the examples are produced by the resource utilization branch of Laiwu Iron and Steel Taidong Industrial Co., Ltd. The converter steelmaking steel slag is treated by open-air water quenching. Accounting for more than 95%, the sludge produced by wet washing ball mill grinding, washing and iron selection. The chemical composition of the steel slag tailings from ball milling is shown in Table 1.

[0027] Table 1 Analysis results of main chemical components of ball mill steel slag tailings

[0028]

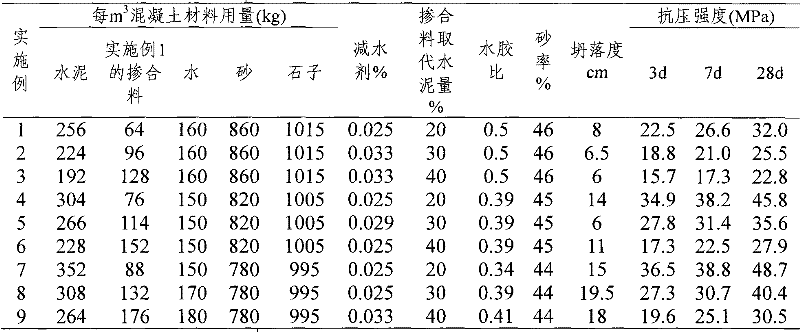

[0029] The raw material of the concrete in the embodiment is as follows:

[0030] P.O 42.5 cement is selected as the cement adhesive; the selected particle size is 5-31.5mm, the mud content is 0.6%, the mud content is 0.3%, the needle-like particle content is 8%, and the crushing index value is 17%. The apparent density ...

Embodiment 1

[0031] Example 1: Ball milled steel slag tailings active powder as concrete admixture and its application in the preparation of concrete

[0032] The active powder of ball-milled steel slag tailings is used as concrete admixture, and the parts by weight are as follows: 100 parts of steel slag tailings and 5 parts of natural gypsum. The preparation method is as follows:

[0033] (1) After simply crushing the large piece of wet ball mill steel slag tailings cake with high water content to 50-100cm, use sunlight and natural wind to dry naturally, so that the water content of the ball mill steel slag tailings reaches 10%;

[0034] (2) The above-mentioned ball-milled steel slag tailings after natural cooling, adopt jaw crusher to crush the large pieces of tailings to below 10cm, and use the steam produced by waste heat boilers in iron and steel enterprises as a heat source to treat the steel slag tails with a water content of 10% The sludge is dried and heat-treated at a temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com