Method for preparing mine filling concrete from wet-ground steel slag pulp

A technology of mine filling and concrete, which is applied in the field of energy-saving building materials, can solve the problems of not considering the stability of steel slag, numerous manufacturing processes, and potential safety hazards, so as to reduce the poor stability of steel slag volume, promote the strength of filling body, and promote the flow sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

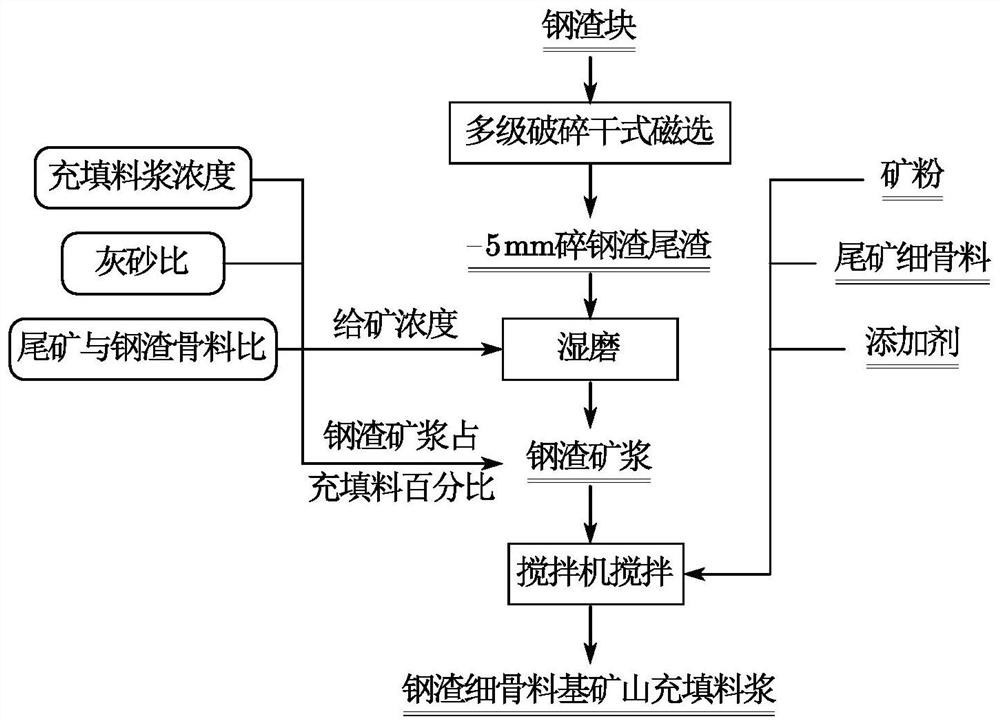

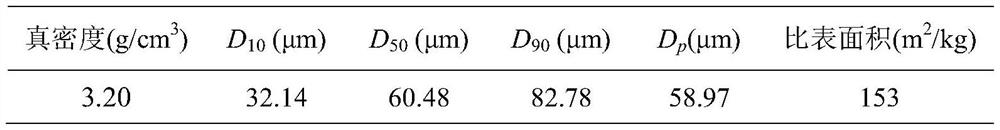

[0032] A method of preparing mine filling concrete by using wet grinding steel slag slurry in this embodiment, such as figure 1As shown, the steel slag raw material is first crushed by a jaw crusher, so that the particle size of the steel slag is less than 15mm, and then the crushed steel slag is crushed by a high-pressure roller mill. After multi-stage crushing, the steel slag has a particle size of -5mm, and then The crushed steel slag is subjected to dry magnetic separation to obtain three kinds of products: steel slag tailings, magnetic separation powder and iron particles, and then the -5mm steel slag tailings after magnetic separation are wet-milled.

[0033] During wet grinding, calculate and set the feeding concentration of wet grinding steel slag according to the slurry concentration, lime-sand ratio of mine filling material, tailings fine aggregate weight and wet grinding steel slag dry weight ratio, and calculate the proportion of steel slag ore slurry in filling mat...

Embodiment 2

[0051] Embodiment 2: Wet grinding steel slag filtrate replaces tap water.

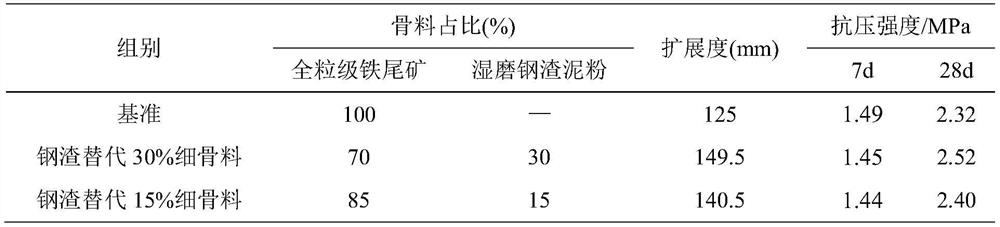

[0052] On the basis of the benchmark group, the filling water was replaced by the wet milled steel slag filtrate to prepare the filling material. The results are shown in Table 3.

[0053] Table 3 Filling properties of wet grinding steel filtrate instead of water

[0054]

[0055]

[0056] After testing, Ca 2+ 、Al 3+ 、Si 4+ The concentrations were 952.57mg / L, 2.28mg / L, and 19.41mg / L, respectively.

[0057] It can be seen from Example 2 that the wet grinding filtrate not only increases the fluidity of the filling slurry, but also enhances the strength of the filling body, because the wet grinding filtrate contains ions that are conducive to promoting the activation of steel slag and other cementitious materials. Therefore, the moisture in the wet-ground steel slag slurry has considerable value, and using it to prepare mine filling concrete is not only environmentally friendly, but also reduces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com