Method for coating LED excited fluorescence powder

A technology of LED light source and phosphor powder, which is applied in the direction of coating, device for coating liquid on the surface, electrical components, etc., can solve the problems of increasing the thickness of the backlight source, which is not conducive to the production of the backlight source, and achieves good stability and light mixing. Uniform, precise color control results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Select a transparent ceramic plate 2 with good thermal conductivity, and use mechanical processing, chemical corrosion or sintering to make a cuboid phosphor filling hole 3, and fill the YAG phosphor 4 directly into the phosphor filling by methods such as filling, depositing, sintering or vapor deposition. In the hole 3, it is directly packaged into a flat phosphor screen structure, and then packaged into a single-chip white LED ( Figure 5 ) or multi-chip white LED ( Image 6 ).

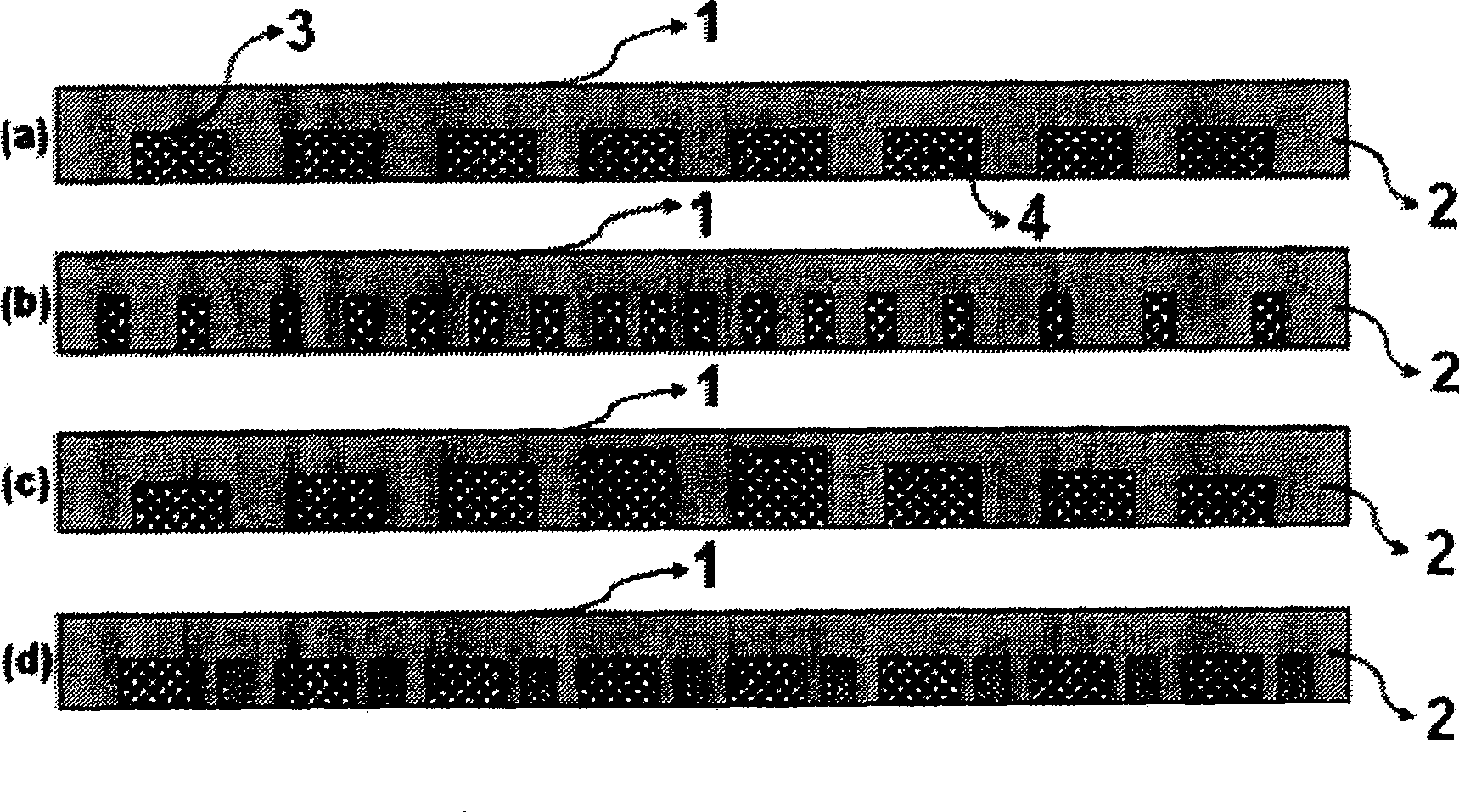

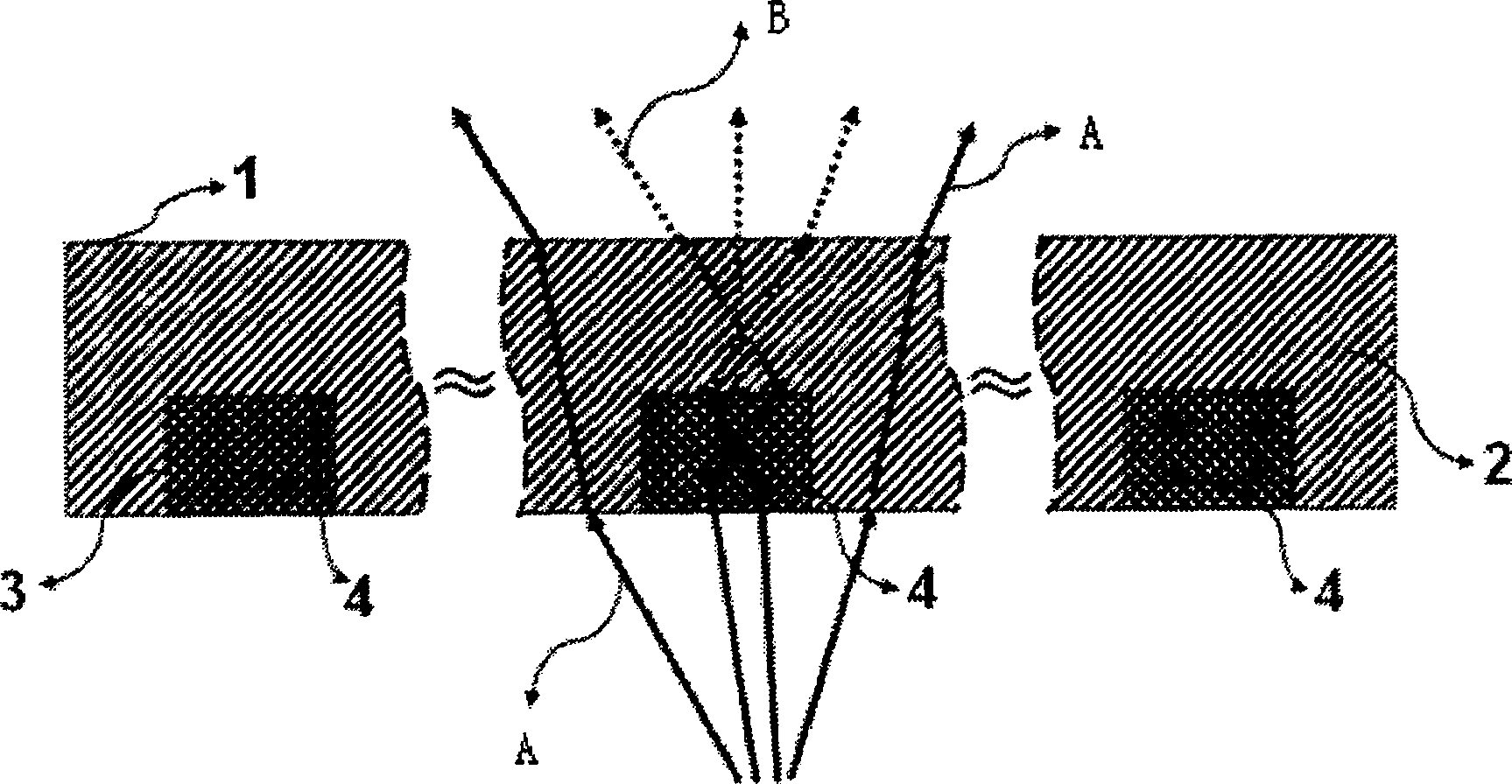

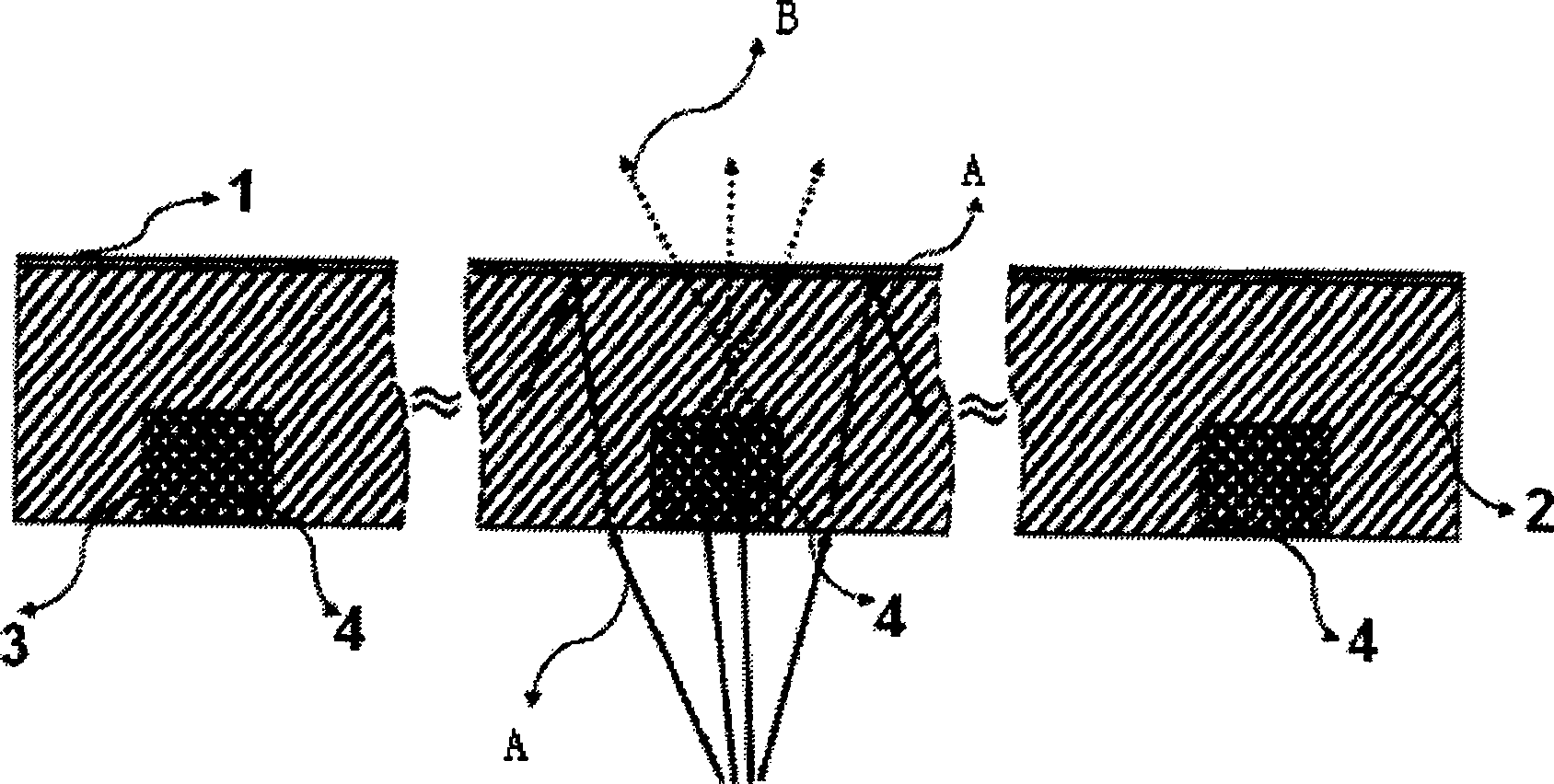

[0025] Since the LED is excited with uniform light intensity, according to the light field distribution, phosphors with uniform depth, uniform size and uniform arrangement are used to fill the holes ( figure 1 a). Such as figure 2 As shown, part of the blue light A excited by the LED is excited by YAG phosphor to produce yellow-green light B, and the other part passes through the area without phosphor to reach the outside, which is still blue light A, and some colors are mixed to form whi...

Embodiment 2

[0028] For LEDs with non-uniform light intensity, according to the distribution of the light field, the arrangement of phosphor powder filled holes 3 can adopt an arrangement of uniform depth, uniform width, and uneven arrangement ( figure 1 b); or use an arrangement with inconsistent depth, uniform width, and uniform arrangement ( figure 1 c); or adopt an arrangement method with consistent depth, inconsistent width, and uniform arrangement ( figure 1 d). Color control is achieved through this arrangement.

Embodiment 3

[0030] In order to be used for ultraviolet LED excitation, a layer of ultraviolet reflection film (1) can also be coated on the upper part of the fluorescent powder screen, so as to avoid the leakage of ultraviolet light in the device. The reflected UV light is either absorbed or re-excited. See image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com