Technique for prevention and control of stored grain by using ozone technology

An ozone technology and pest technology, applied in the field of stored grain pests, can solve problems such as increased residues, decreased hygienic quality, and damage to the health of employees, and achieve the effects of preventing heat and mildew in stored grains and good bactericidal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Its main control steps of the present invention are as follows:

[0027] A. The insecticidal season for stored grains is from April to June in the Gregorian calendar. This period of time is chosen in consideration of the temperature of the upper layer>middle layer>lower layer of the grain pile during this period. Generally, stored grain pests are thermotropic, and the temperature difference also promotes the accumulation of pests upwards. , easy to kill insects;

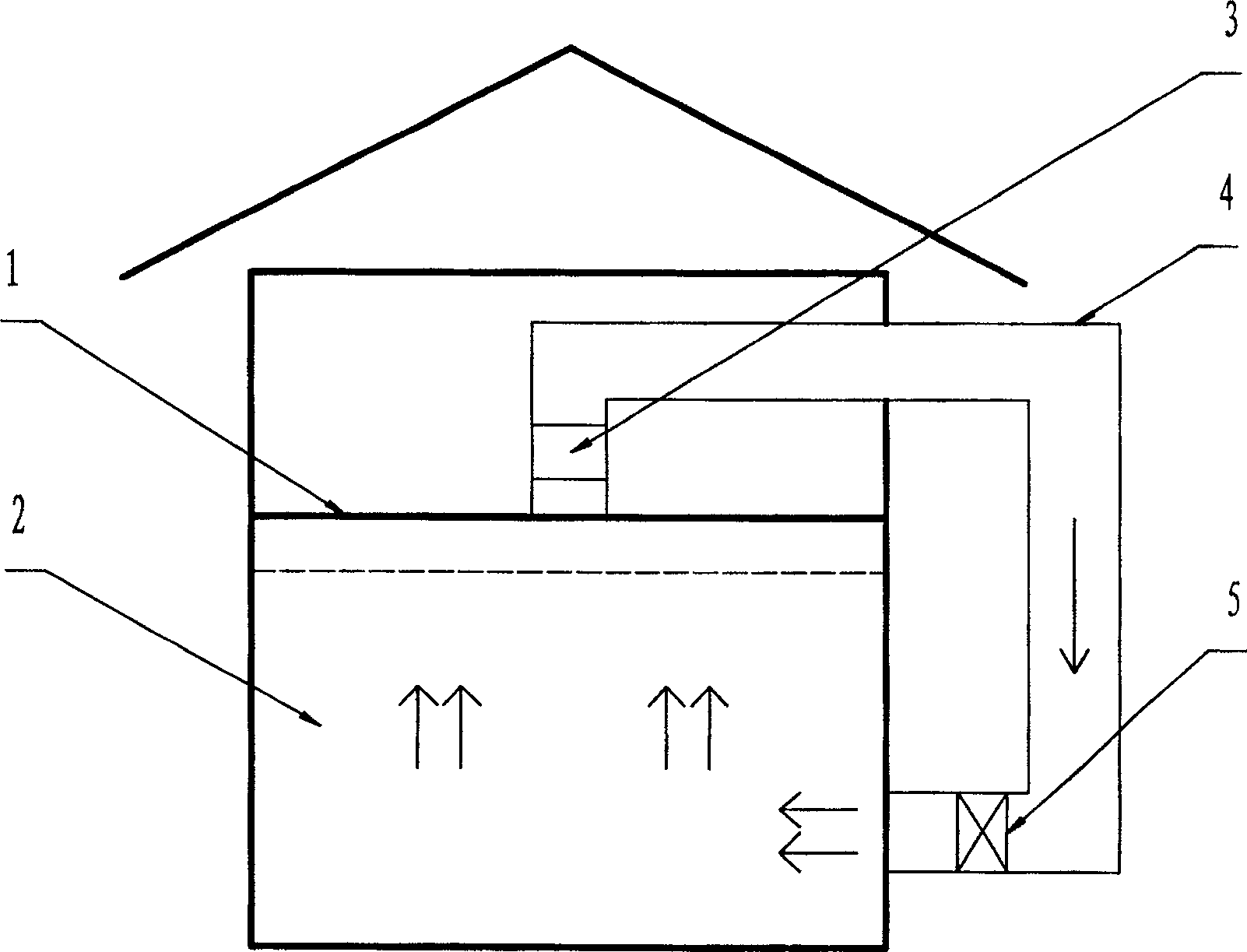

[0028] B. Use a polyvinyl chloride film 1 with a thickness of 0.2 microns to seal the surface of the grain pile 2 for 18 days. At this time, the grain pile 2 is in a sealed state, due to the respiration of the grain, microorganisms and pests, gradually consume part of the grain pile Oxygen and increase the content of carbon dioxide. Because the specific gravity of carbon dioxide is greater than that of air, it sinks slowly. In addition, the plastic film has allowed micropores, so the oxygen concentration in th...

Embodiment 2

[0032] Its main control steps of the present invention are as follows:

[0033] A. The season for storing grain and killing insects is September in the Gregorian calendar;

[0034] B. use the polyvinyl chloride film 1 that thickness is 0.15 micron to seal the grain pile 2 surface layer for 20 days;

[0035] C. If figure 1 As shown, the ozone generator 3 is poured into the grain pile 2 with a concentration of 10 ppm ozone for 18 hours from the bottom of the grain pile 2 through the circulating pipe 4, and the ozone is accelerated by the wind force of the blower fan 5 and enters the grain pile 2 from bottom to top, thereby deterring pests. Drive to the upper layer of the grain pile 2, and the situation of the pests can be observed through the observation port 8 left on the film 1;

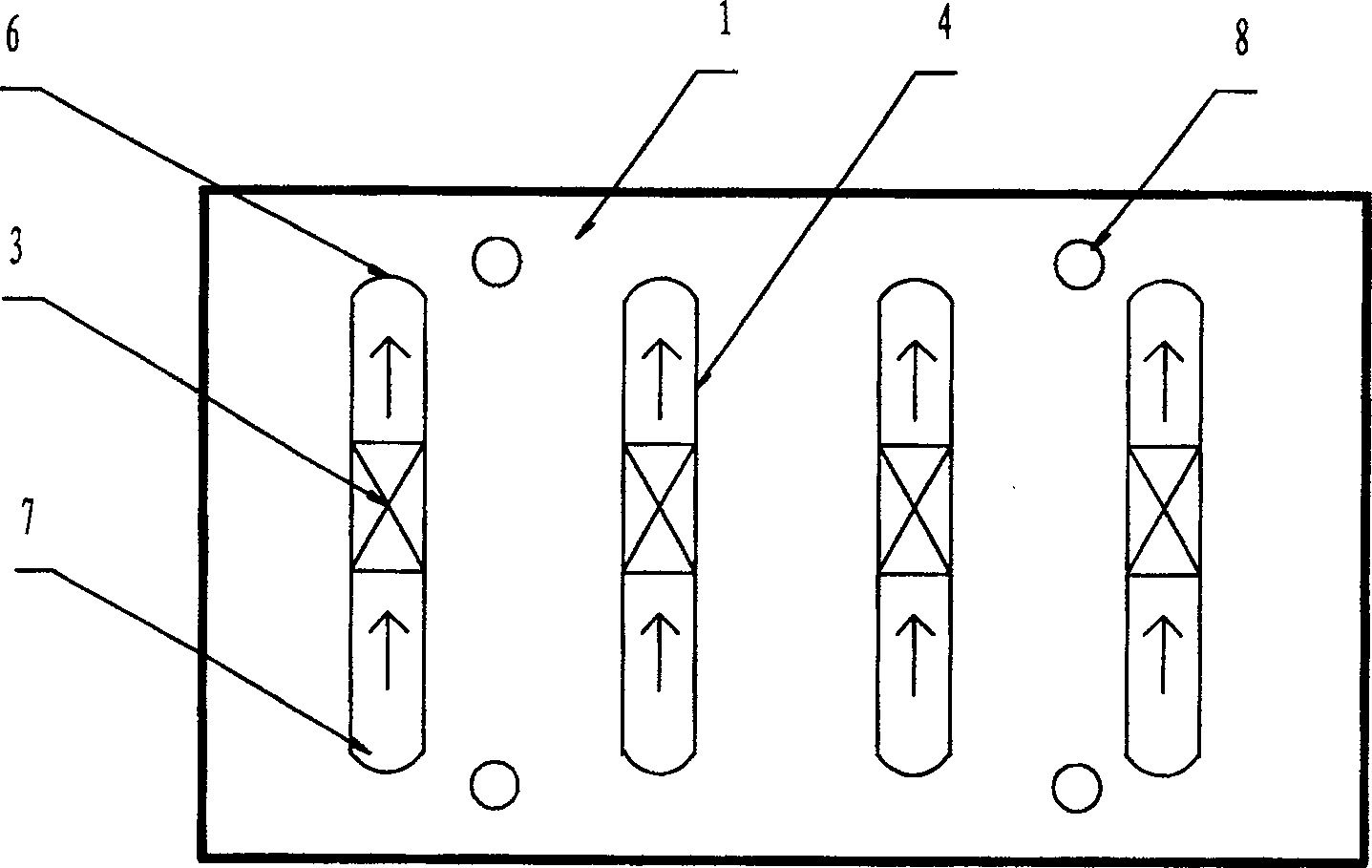

[0036] D. If figure 2 Shown, now with four ozone generators 3 ozone through circulation tube 4 docking eight bell mouths reserved on the film 1, the concentration that ozone generator 3 produces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com