Variable plunger pump system for drilling machine

A plunger pump, variable technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of troublesome pipeline connection and dismantling, oil pump and valve failure damage, and many connecting pipelines, etc., to achieve good controllability and stability, Start and stop without impact, compact and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

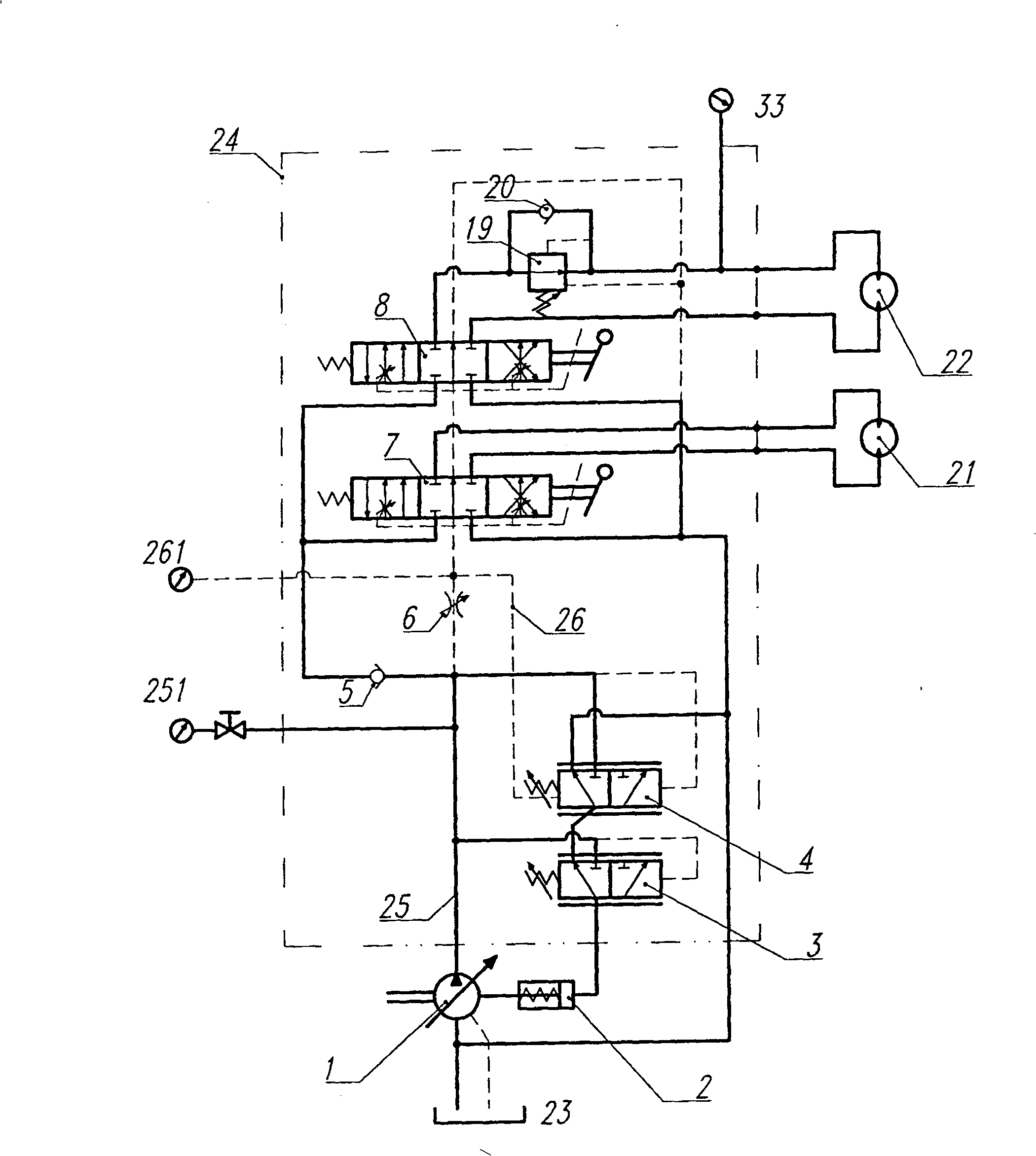

[0037] see figure 1 , 2 As shown, the present invention is combined with a slice valve and then connected with a plunger pump to form a whole. , Rotary motor control valve 7, upper and lower motor control valve 8, pressure reducing valve 19, check valve 20, rotary motor 21 and upper and lower motor 22.

[0038] Wherein, the pressure limiting valve 3 and the flow control valve 4 are installed in the pressure limiting flow valve body 34, the pressure limiting valve 3 is composed of a pressure limiting spool 31 and a return spring 32; the flow control valve 4 is composed of a flow control spool 41 and a return spring 42; the non-return one-way valve 5 and the regulating valve 6 are installed in the one-way regulating valve body 56; the pressure reducing valve 19 and the one-way valve 20 are installed in the one-way pressure reducing valve body 18;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com