Bipolar transistor and method of fabricating the same

A bipolar transistor and base technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of increasing the number of manufacturing steps and increasing manufacturing costs, so as to reduce series resistance and improve high-frequency performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The figures are not drawn to scale. Generally, like parts are indicated by like reference numerals in the drawings.

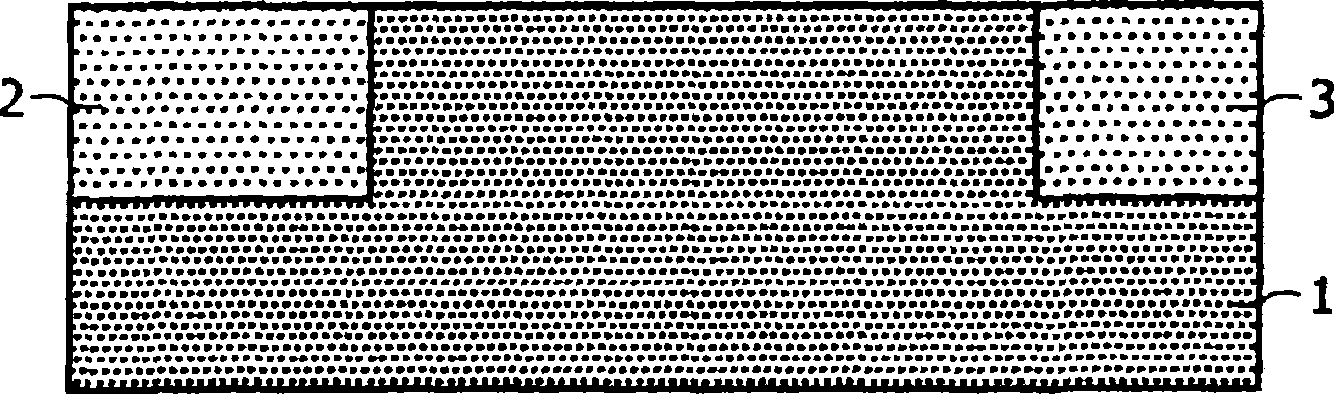

[0017] figure 1 An initial structure is shown comprising a silicon substrate 1 provided with two shallow trench isolation regions 2 and 3 fabricated using standard CMOS fabrication techniques. The shallow trench isolation regions 2 and 3 may include silicon dioxide or any other insulating material.

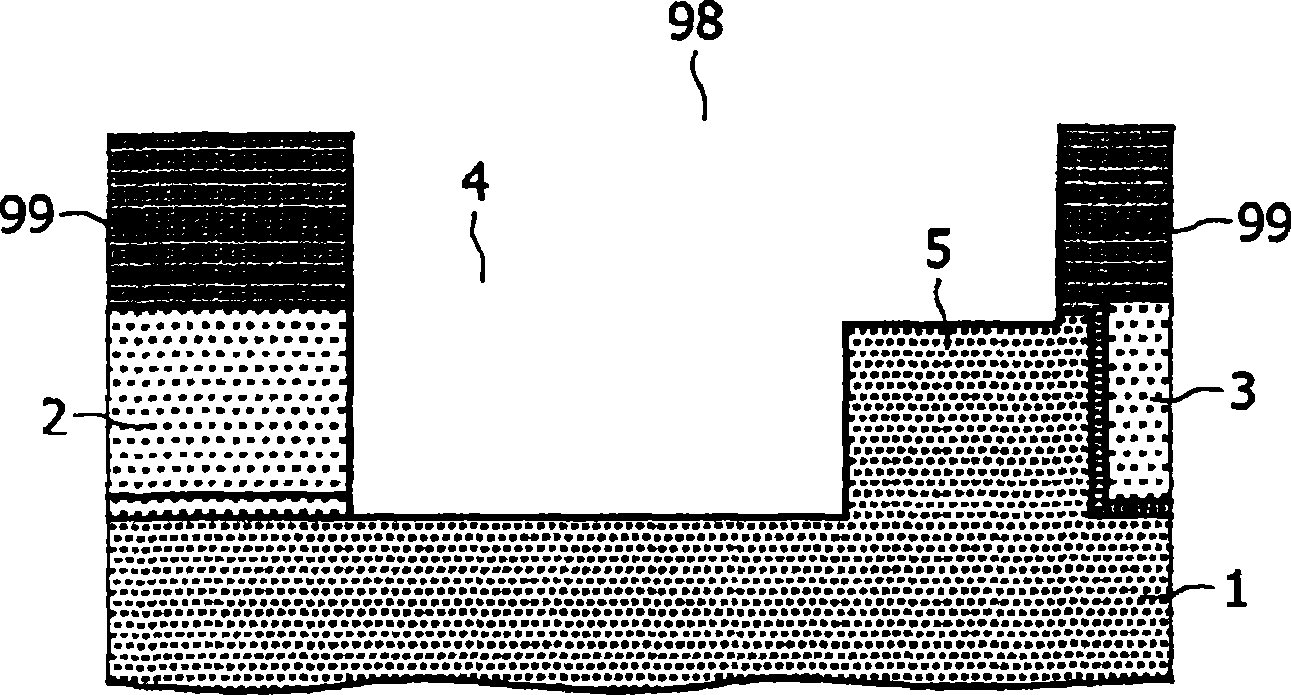

[0018] Next, if figure 2 As shown, a resist layer 99 is formed, and a transistor opening region 98 is formed by photolithography, exposing a part of the shallow trench isolation region 2 and a part of the silicon substrate 1 . The exposed portion of the shallow trench isolation region 2 is selectively etched with respect to the silicon substrate 1 . At this time, grooves 4 and protrusions 5 are formed, and protrusions 5 contain silicon substrate 1 . The trench 4 has a first sidewall adjacent to the shallow trench isolation region 2 , a second sidewall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com