Little oil gasification and burning lateral-igniting center coal powder-feeding swirling burner

A swirl burner and burner technology, which can be used in the burner, burner, combustion ignition and other directions of burning powder fuel, and can solve problems such as wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

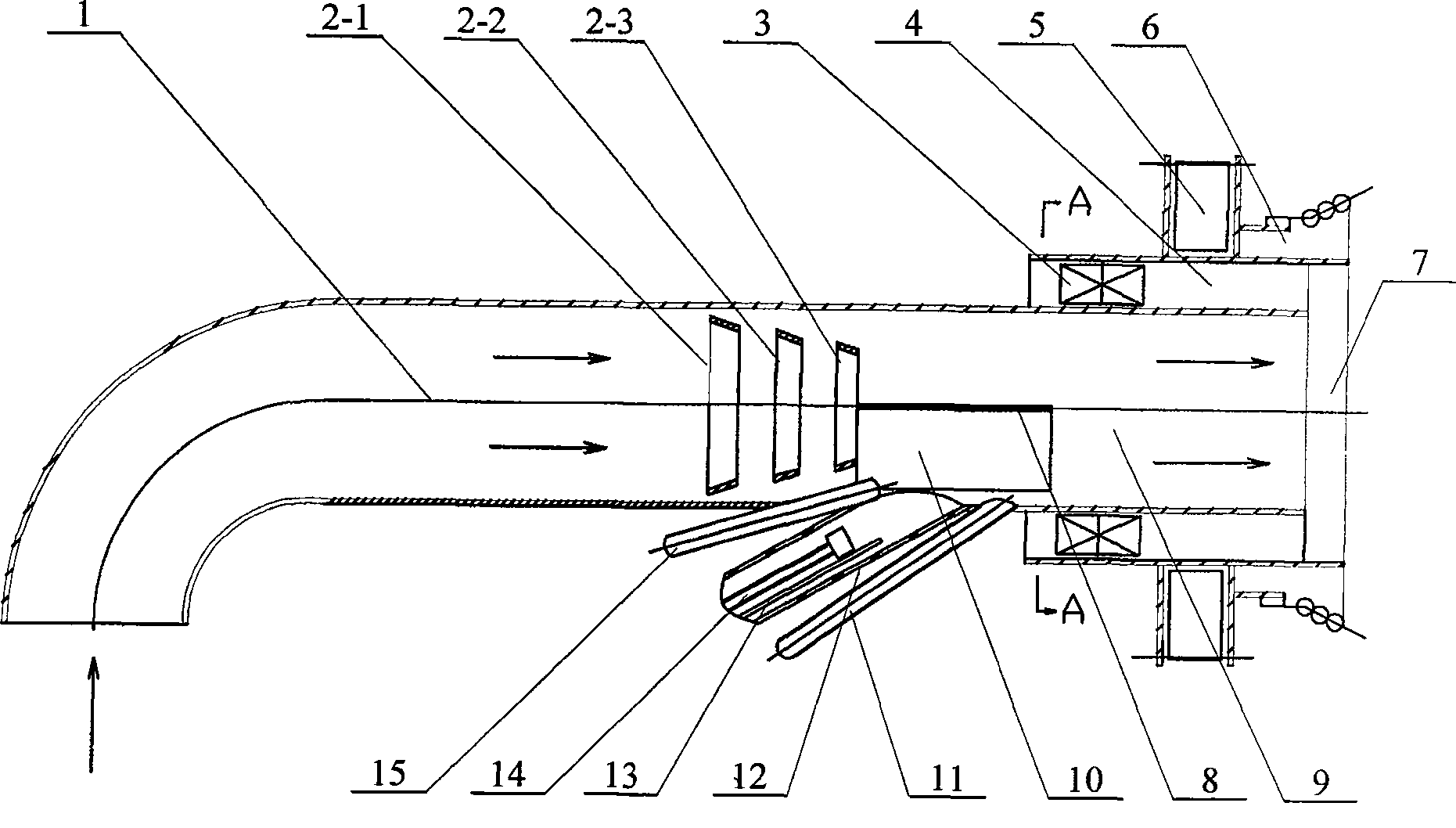

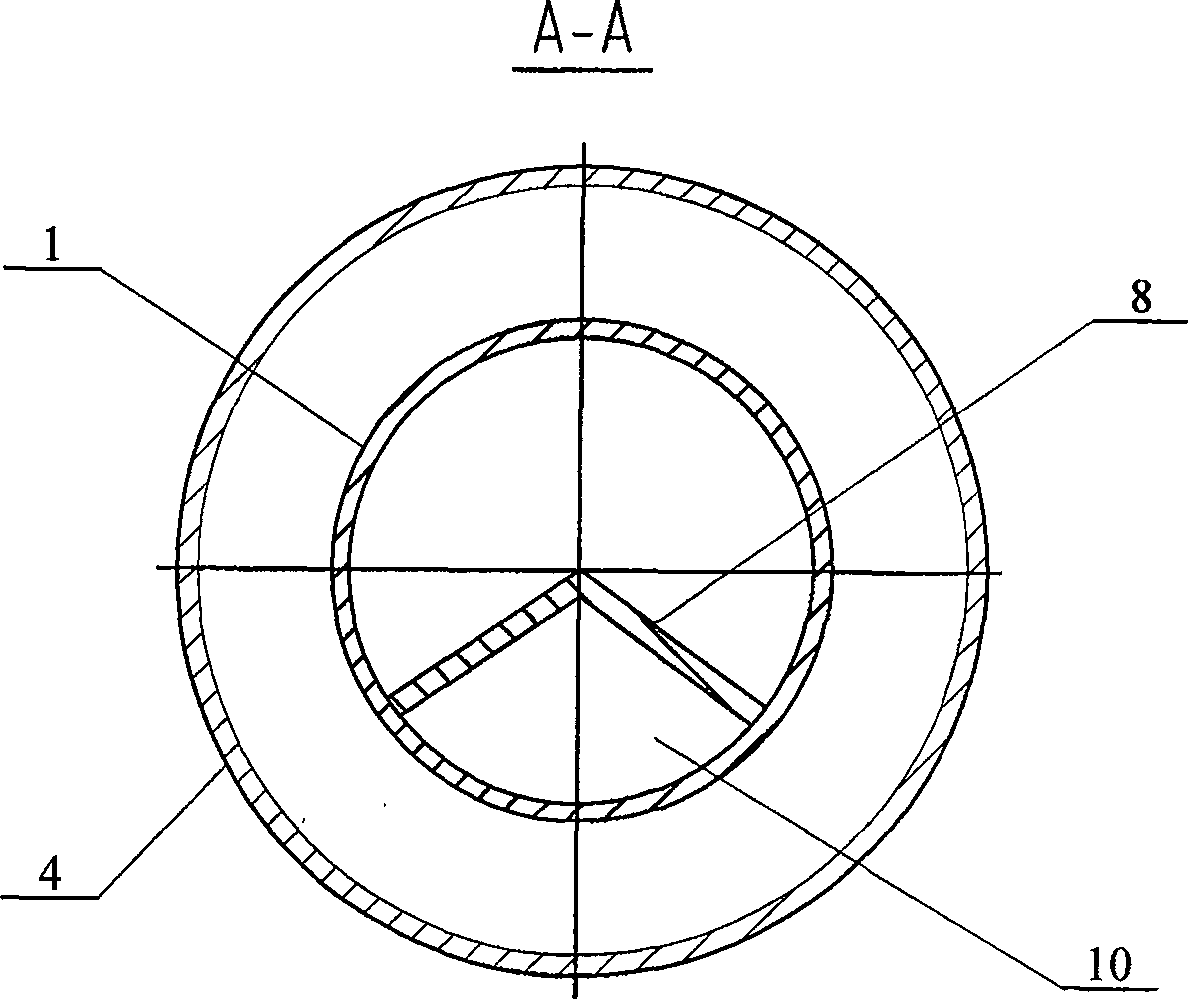

[0006] Specific implementation mode one: (see figure 1 , figure 2 ) This embodiment consists of a burner primary air duct 1, a first truncated conical separating ring 2-1, a second truncated conical separating ring 2-2, a third truncated conical separating ring 2-3, an inner swirler 3, and a burner Inner secondary air duct 4, external swirler 5, burner outer secondary air duct 6, burner 7, inverted "V"-shaped partition 8, secondary combustion chamber 9, primary combustion chamber 10, auxiliary oil gun 11. The main oil gun casing 12, the ignition gun 13, the main oil gun 14 and the flame detection tube 15. The outlet end of the primary air duct 1 of the burner is the burner 7, and the secondary air duct 4 in the burner is fixed on the burner On the outer surface of the outlet end of the primary air duct 1, the inner swirler 3 is fixed between the primary air duct 1 of the burner and the secondary air duct 4 inside the burner, and the outer swirler 5 is fixed on the secondary ...

specific Embodiment approach 2

[0007] Specific implementation mode two: (see figure 1 ) The heads of the main oil gun 14, auxiliary oil gun 11, ignition gun 13 and main oil gun casing 12 of this embodiment are arranged in the direction of the burner nozzle 7 of the primary air duct 1 of the burner. On one side, the afterbody of main oil gun 14, auxiliary oil gun 11, ignition gun 13 and main oil gun sleeve pipe 12 is warped outwards, and main oil gun 14, auxiliary oil gun 11, ignition gun 13 and main oil gun sleeve pipe 12 and The included angle of the center line of the burner is 55°~65°. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0008] Specific implementation mode three: (see figure 1 ) The included angles between the main oil gun 14, the auxiliary oil gun 11, the ignition gun 13 and the main oil gun casing 12 of this embodiment and the centerline of the burner are all 60°. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com