Oil gas field waste drilling fluid drill chip innocent treatment agent and method

A technology of harmless treatment and drilling fluid, which is applied in chemical instruments and methods, sludge treatment, climate change adaptation, etc. It can solve the problems of multiple treatments, occupying cultivated land, and large amount of treatment agent, so as to facilitate plant growth , treatment cost control, and the effect of loose drilling cuttings structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

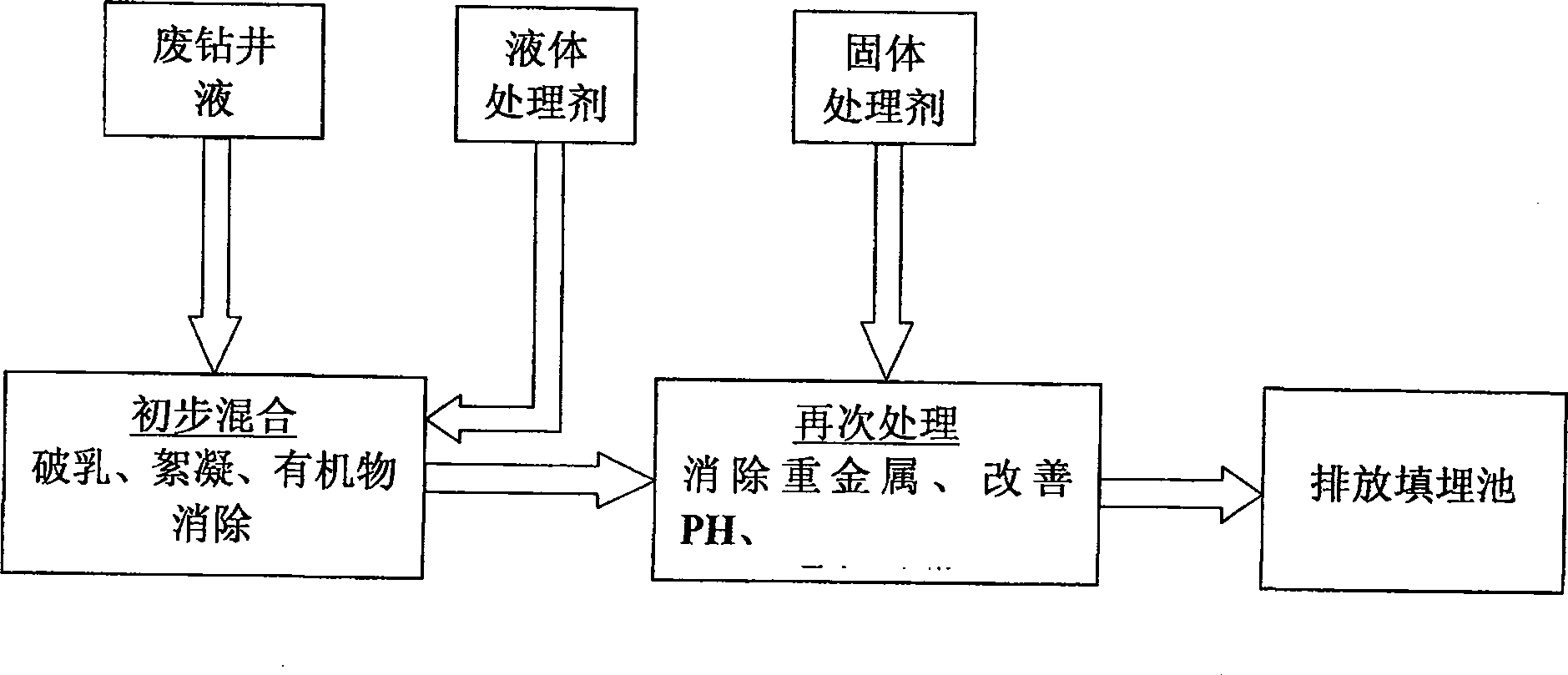

Method used

Image

Examples

Embodiment

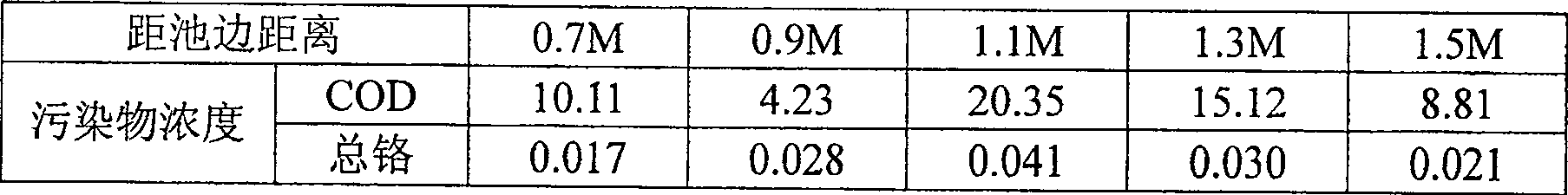

[0033] Example: the data of harmless treatment in a certain well.

[0034] (1): The drilling fluid system used in drilling is polymer dispersed drilling fluid, and the completion depth is 2114 meters. The drilling fluid includes 76.5 tons of barite powder, 1.5 tons of sodium carbonate, 0.5 tons of chromium-free lignin, 0.29 tons of CMC, 0.5 tons of K-PHP, 2.5 tons of FT-881, 3 tons of caustic soda, and 4.8 tons of iron-chromium lignosulfonate 15.7 tons of RT-001, 0.357 tons of MA-871, 0.2 tons of safflower powder, and a total of about 600 tons of drilling cuttings and waste drilling fluid.

[0035] (2): The addition ratio of liquid treatment agent is 8%, and the addition ratio of solid treatment agent is 4% (Note: According to the prior inspection, this amount can ensure that after treatment, the product meets GB5085.1-1996 "Hazardous Waste Identification Standard" -Leach Toxicity Identification", GB5085.3-1996 "Identification Standard for Hazardous Waste-Corrosive Identifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com