Tobacco leaf automatically boxing storage method

A cigarette box and tobacco leaf technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of high space development of difficult workshops, reduced equipment utilization rate, intricate conveying paths, etc., to achieve simple and clear connection methods and conveying paths, and improve stability. reliability and reliability, the effect of simplifying the automation control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

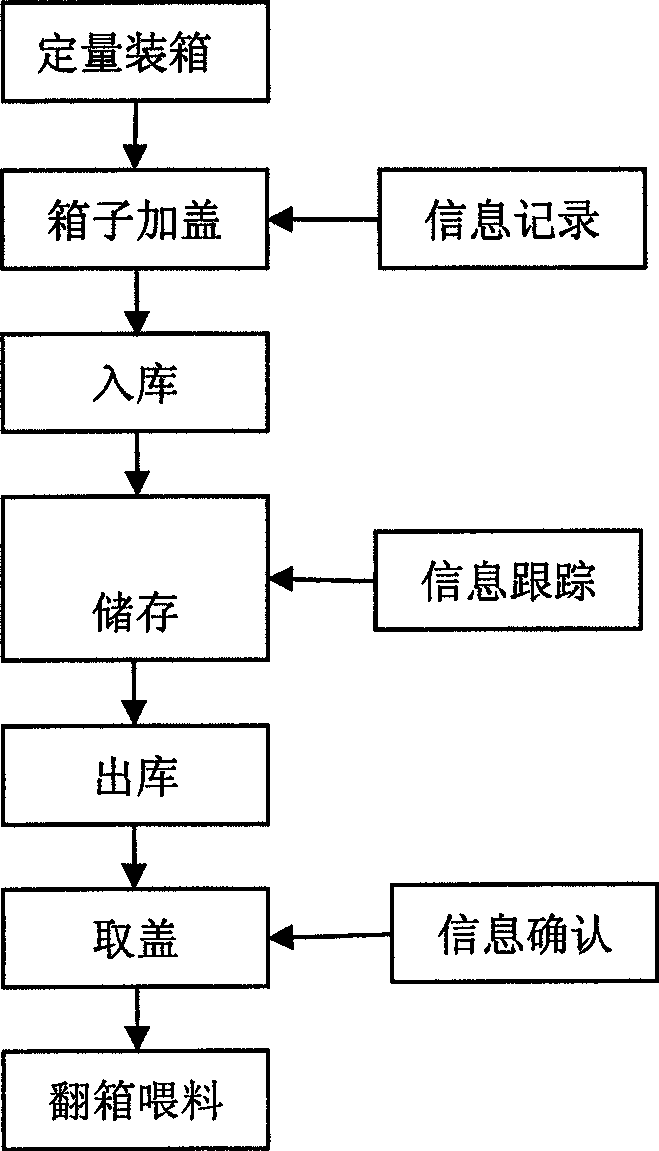

[0026] Using the method of the present invention, it is necessary to construct a box-type storage system consisting of a tobacco box for storing tobacco leaves, a three-dimensional warehouse, a conveying device, a capping and capping device, a weighing device, and an information management system, and according to the following procedures: figure 1 The process flow shown to carry out leaf storage, the method is as follows:

[0027] (1) Quantitative boxing: the tobacco leaves are packed into the smoke box continuously sent from the conveying line according to the set amount;

[0028] (2) Box capping, weighing and recording information: Cover the cigarette box loaded with tobacco leaves on the conveying line and weigh it with an electronic weighing device connected to the information management system, and the information management system automatically records the electronic weighing The information transmitted by the device and write the information into the electronic label o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com